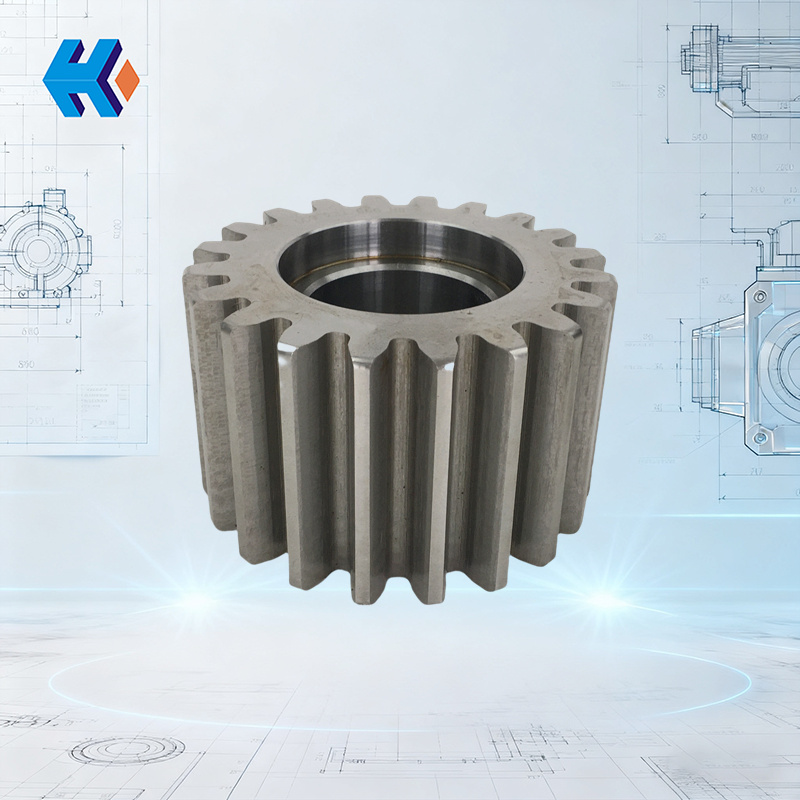

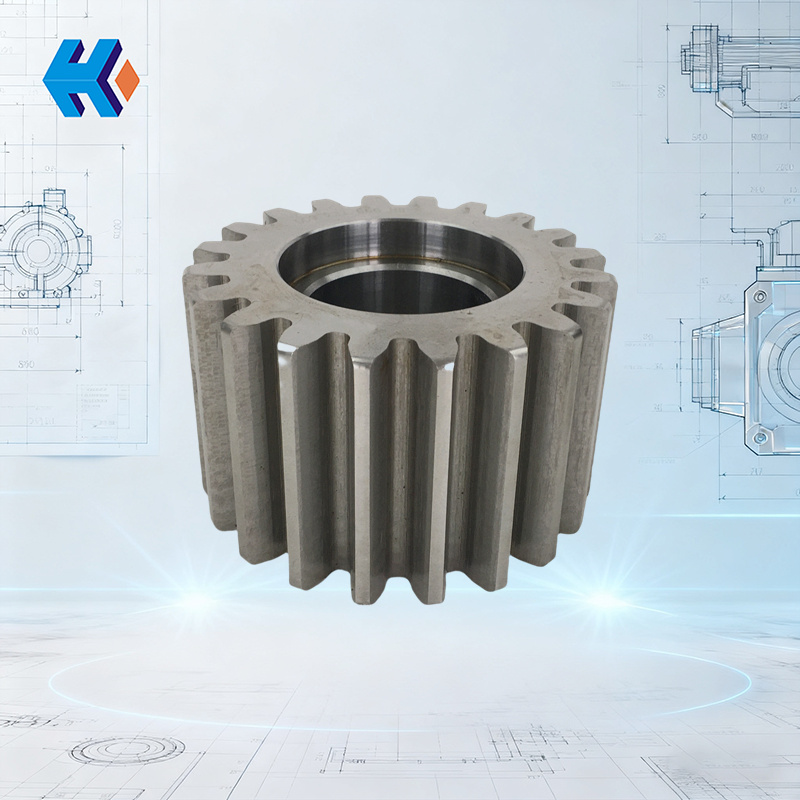

Steam Turbine Turning Gear Swinging Pinion

Product Overview

The steam turbine turning gear swinging pinion is a core functional component of the turning gear transmission system. As a crucial link connecting the turning gear drive mechanism and the rotor turning gear, it achieves low-speed rotational control of the rotor before the steam turbine starts, after it shuts down, and during standby through precise swinging engagement and automatic disengagement. This gear directly determines whether the turning gear can smoothly turn the rotor and also ensures reliable disengagement from the rotor when the steam turbine is brought up to speed. It is the core transmission element that ensures uniform heating/cooling of the rotor and prevents bending deformation.

Core Functions and Working Characteristics

Precise Engagement and Disengagement Control

As a movable transmission mechanism, the swinging pinion is connected to the piston rod of the pneumatic actuator and the operating handle via a rocker arm. It achieves precise swinging rotation around the active gear shaft as the center. When the rocker arm rotates clockwise to a set position, it can quickly engage with the rotor turning gear, transmitting the drive torque. When the steam turbine's rotor speed exceeds the turning gear speed after it is brought up to speed, it automatically swings counter-clockwise and disengages under the action of the reaction torque, ensuring interference-free operation. The engagement and disengagement processes are responsive and without jamming.

Bidirectional Transmission Adaptability

- When the steam turbine is turned off, the swinging pinion acts as the driving wheel. It rotates clockwise to drive the turning gear, and the reaction torque keeps the engagement stable, ensuring the rotor rotates at a uniform speed.

- When the steam turbine is brought up to speed, the turning gear becomes the driving wheel, causing the swinging pinion to rotate passively. The resulting counter-clockwise torque causes it to automatically disengage, achieving safe separation without power intervention.

Technical Parameters

- Transmission Adaptability: Precisely engages with the turning gear and the small gear on the active shaft to transmit the motor's driving torque.

- Motion Characteristics: The swinging angle is precisely controllable. The gap with the turning gear is uniform during engagement, and there is no interference after disengagement.

- Operating Speed: Matches the 1.5 r/min turning speed and can withstand the instantaneous impact load during startup.

- Interlock Adaptability: Interlocks with the jacking oil system and the turning gear motor travel switch to ensure safe operation.

- Material Selection: Made of high-strength alloy structural steel, which is tempered and has its tooth surface strengthened to combine wear resistance and toughness.

Product Advantages

- Ensures Rotor Safety: Ensures the rotor rotates uniformly at low speed through stable transmission, preventing bending caused by uneven temperatures or gravity and reducing the risk of rubbing between dynamic and static parts.

- Reliable Automatic Clutch: Can automatically disengage during startup and engage during shutdown without manual intervention, adapting to the "automatic engagement/disengagement" feature of the turning gear device.

- Compatible with Multiple Operation Modes: Perfectly adapts to both manual and automatic operation needs. Even with abnormal jacking oil pressure, it can cooperate with system interlocks to ensure safety.

- Long-Term Stable Operation: The structural design is optimized for low-speed turning conditions. The material and manufacturing process meet the requirements for frequent startup and shutdown, giving it a long service life.

- Strong System Synergy: Works precisely with components such as the turning gear motor, pneumatic actuator, and travel switch, integrating into the overall safety control logic of the unit.

Application Scenarios

Used in the transmission system of the steam turbine turning gear device. It is a core component for turning operations before steam turbine startup for preheating, after shutdown for cooling, and during long-term standby. It ensures the rotor remains straight under various operating conditions, providing a crucial guarantee for the unit's safe startup and stable operation.

Custom Fabrication per Drawings

We provide precision manufacturing of steam turbine turning gear swinging pinions strictly based on your technical drawings. Our production complies with your specified material standards, key parameters, tooth surface treatment requirements, and interlock matching specifications. We also conduct torque and engagement/disengagement tests to ensure each pinion integrates seamlessly with your turning gear system, whether for maintenance replacement or new unit assembly.

Protect Rotor Safety—Trust Our Turning Gear Swinging Pinion!

Our swinging pinions deliver reliable automatic clutch, stable low-speed transmission, and long service life. Contact us now for a customized quote,performance test reports. We guarantee on-time delivery and after-sales support to keep your turbine's turning gear system running safely.