Dongfang SRI Engineering Co., Ltd

zq-zhang@hksri.com

Call Us

+86 838 2303231

Products

Dongfang SRI Engineering Co., Ltd

-

Product Overview-ZGM Pulverizer Coupling Pin 20MG40.11.02.J

The is a specialized core spare part for the main reducer coupling of ZGM-type medium-speed roller coal pulverizers. Its primary functions include torque transmission¥ 0.00Buy now

-

ZGM113N Mill Hinge Shaft 20MG40.11.11.02 High-Toughness Transmission Pivot

The Hinge Shaft 20MG40.11.11.02 is a core transmission spare part for the ZGM113N medium-speed coal mill.¥ 0.00Buy now

-

Maintenance Guide and Technical Specifications for 20MG42.11.09 ZGM Coal Mill Grinding Roller Sleeve

The roller sleeve 20MG42.11.09 for Bowl-Type Medium-Speed Coal Mills is a core grinding component of the ZGM series.¥ 0.00Buy now

-

20MG60.11.12.06.02 ZGM Medium-speed Pulverizer Upper Seal Sleeve

In the sealing and protection system of the ZGM Medium-speed Pulverizer, the Upper Seal Sleeve (Part No. 20MG60.11.12.06.02) is a critical component located in the upper grinding zone.¥ 0.00Buy now

-

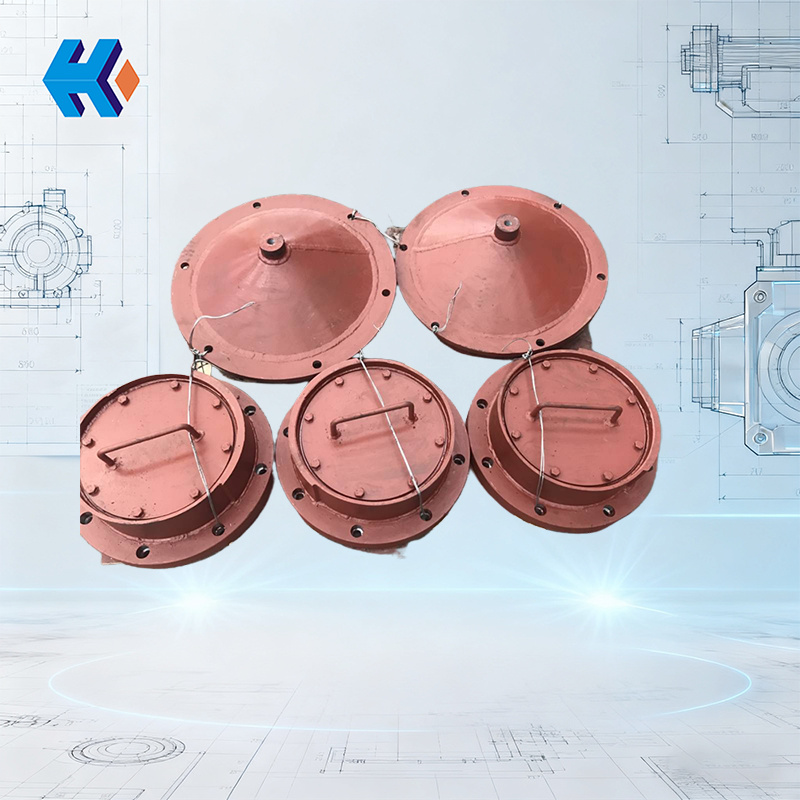

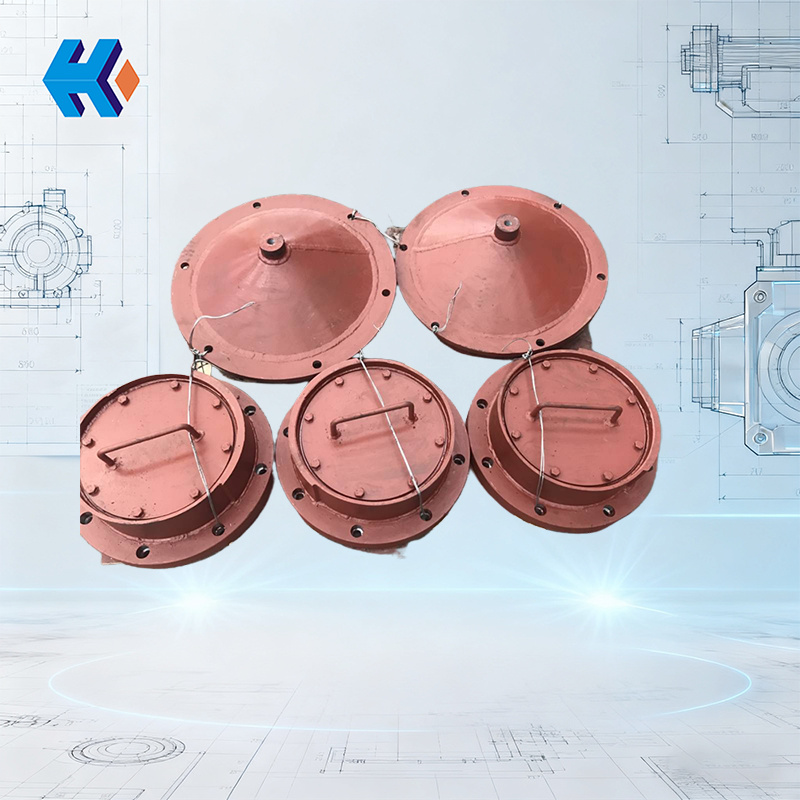

Protective Cover 20MG30.11.09.03J-Ensuring Structural Integrity of ZGM Coal Mill Roller Assemblies

The Protective Cover (Part No. 20MG30.11.09.03J) is a critical safety and shielding component of the roller assembly, responsible for isolating moving parts, blocking dust infiltration, and ensuring maintenance safety.¥ 0.00Buy now

-

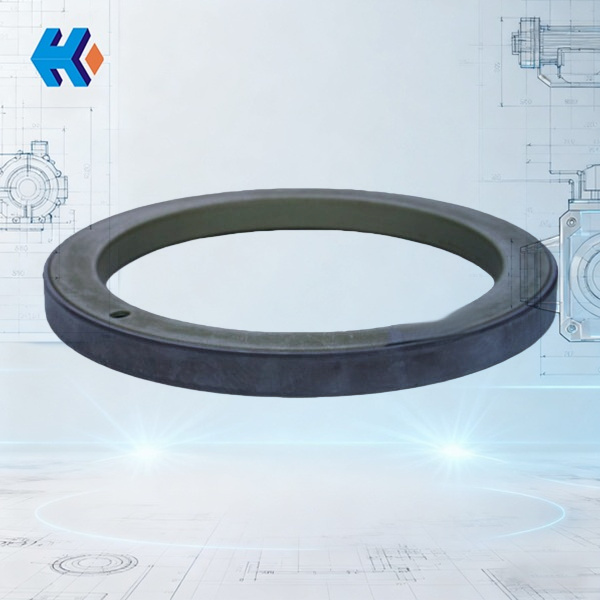

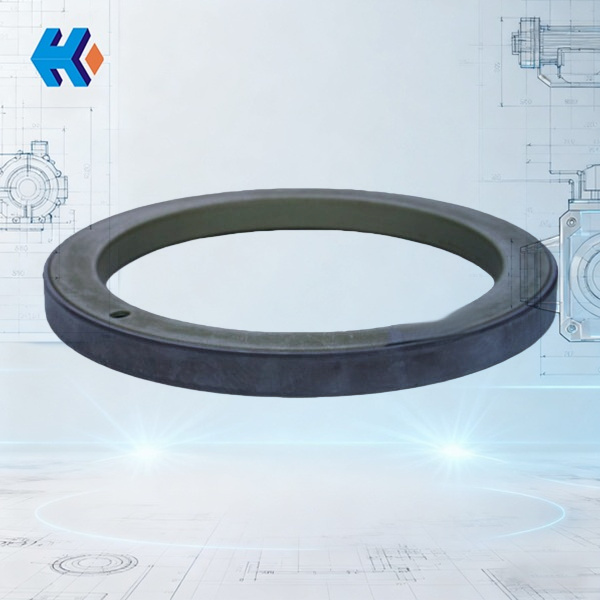

Oil Seal Bracket 20MG43.11.09.37: Core Positioning Component for ZGM Medium-Speed Coal Mill Sealing Systems

In the sealing system of ZGM-type medium-speed roller coal mills, the Oil Seal Bracket (Part No. 20MG43.11.09.37) serves as the core positioning and load-bearing component.¥ 0.00Buy now

-

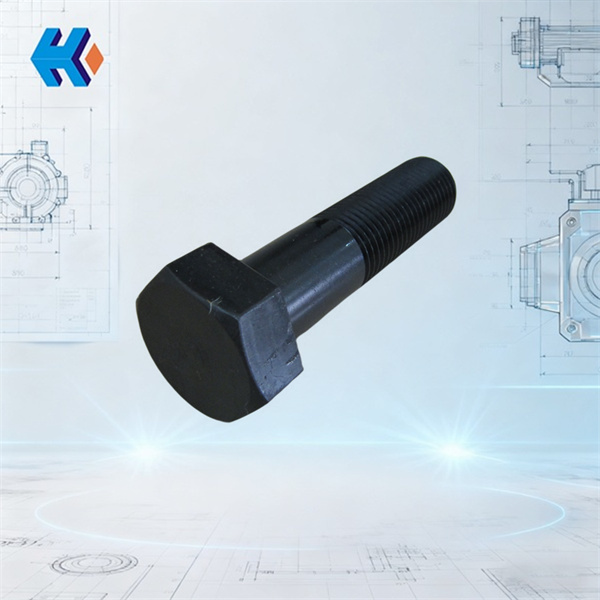

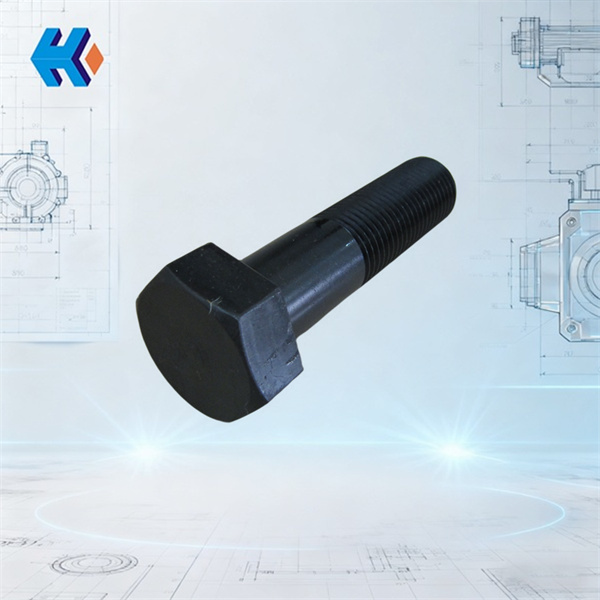

200MG41.11.09.77 Fastening Bolt for ZGM123G Coal Mill Roller Assembly

The Fastening Bolt 200MG41.11.09.77 is a high-strength specialized fastener designed for the roller assemblies of medium-speed coal mills.¥ 0.00Buy now

-

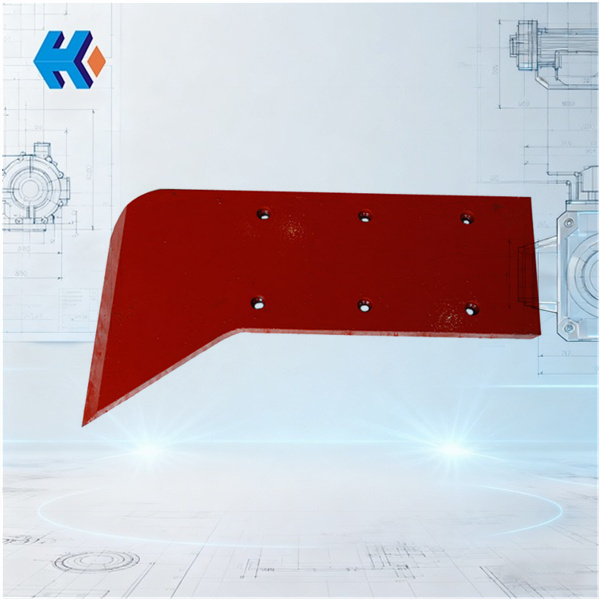

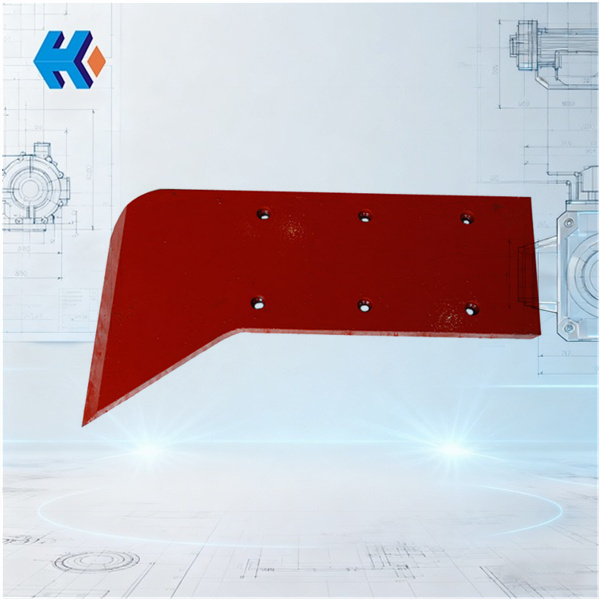

Technical Specifications: 200MG41.11.09.71 Roller Assembly Wear Plate

The Wear Plate 200MG41.11.09.71 is a specialized protective spare part designed for the roller assembly of ZGM95G medium-speed pulverizers.¥ 0.00Buy now

-

20MG42.11.09.01 ZGM Medium-Speed Pulverizer Roller Breather

In the operational protection system of the ZGM medium-speed pulverizer roller assembly, the breather serves as a critical pressure regulation and dust-proof sealing component.¥ 0.00Buy now

-

Technical Profile-Fastening Bolt 200MG41.11.09.77

The Fastening Bolt 200MG41.11.09.77 is a high-strength specialized component engineered specifically for the grinding roller assembly of medium-speed coal pulverizers.¥ 0.00Buy now

-

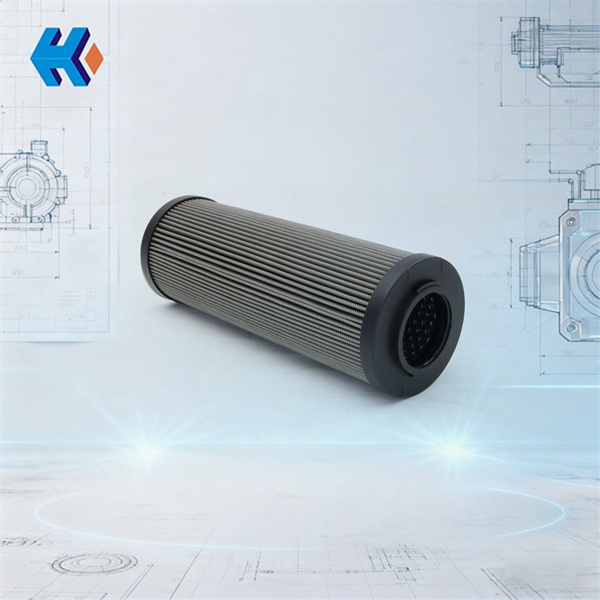

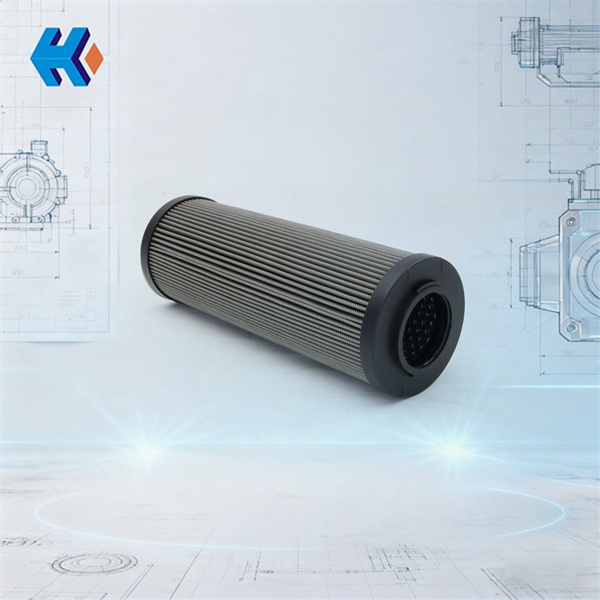

Replacement of 20MG30.20.03.02 Coal Mill Duplex Filter Element

Today, using the Coal Mill Duplex Filter Element 20MG30.20.03.02 as an example, we will guide you on how to minimize hydraulic oil loss during replacement and ensure smooth air bleeding and stable system operation.¥ 0.00Buy now

-

20MG33.11.08.97BZ Medium-Speed Coal Pulverizer Liner

In power plants, the medium-speed coal pulverizer is a core component of the milling system, and the Liner 20MG33.11.08.97BZ is an indispensable part of this equipment.¥ 0.00Buy now

Our company specializes in manufacturing main and auxiliary equipment such as coal mills, fans, boilers, and precision parts for steam turbines and generators, providing core equipment and technical support for the fields of power plants, metallurgy, chemical industry, etc.