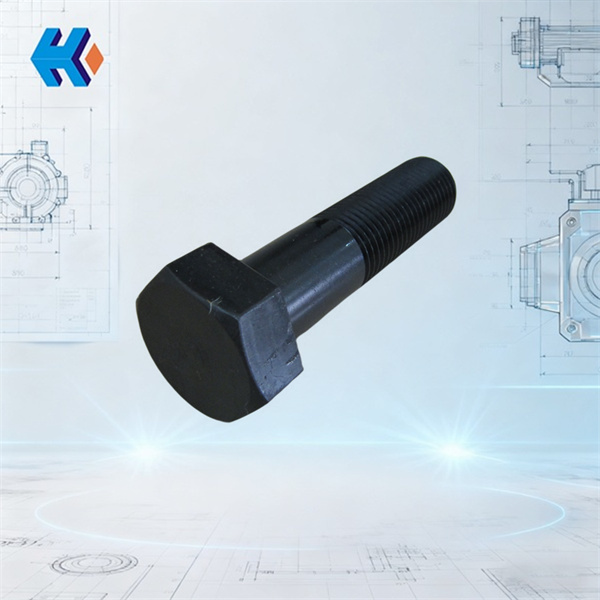

200MG41.11.09.77 Fastening Bolt for ZGM123G Coal Mill Roller Assembly

I. Product Overview

The Fastening Bolt 200MG41.11.09.77 is a high-strength specialized fastener designed for the roller assemblies of medium-speed coal mills. It is specifically engineered to meet the connection requirements of the ZGM series, particularly the ZGM123G medium-speed roller coal mill.

As the primary component responsible for grinding pressure, the roller assembly subjects its connecting bolts to alternating loads, impact forces, and vibrational stress during rotation and the grinding process. Consequently, these bolts must meet rigorous standards for tensile strength, hardness, and fatigue resistance. As a critical wear part, this bolt must be inspected during mill overhauls for thread wear or plastic deformation and replaced according to maintenance specifications to ensure the structural integrity of the ZGM123G grinding system.

II. Technical Features & Advantages

1. High-Strength Material and Mechanical Properties

The bolt is manufactured from a specialized high-strength alloy specifically for coal mill applications. Its mechanical parameters are precision-matched to the loading requirements of the ZGM123G roller assembly.

| Technical Parameter | Specification Value | Maintenance Standard Compliance |

| Tensile Strength ($R_m$) | $\ge 1000$ MPa | High-load grinding pressure support |

| Yield Strength ($R_{p0.2}$) | $\ge 900$ MPa | Prevents permanent deformation under impact |

| Vickers Hardness | $320 \sim 380$ HV | Balanced wear resistance and toughness |

| Surface Treatment | Black Oxide (Blackening) | Anti-corrosion and optimized thread lubrication |

2. Precision Fit and Assembly Synergy

Designed to strict OEM standards, this bolt ensures a perfect fit with the roller oil seal support ring, shaft sleeve, and other surrounding components.

-

Assembly Compatibility: Pairs seamlessly with Oil Seal Support Ring 20MG40.11.09.83 and Shaft Sleeve 20MG40.11.09.84.

-

Maintenance Efficiency: High-precision threading allows for rapid installation and removal, reducing downtime during scheduled mill outages.

3. Durability and Lifecycle Matching

The design life of the bolt is synchronized with the maintenance cycles of the roller tires and liners. By ensuring consistent batch performance, these bolts reduce the frequency of unplanned shutdowns, maintaining mill availability throughout the wear cycle of the grinding elements.

III. Application Scenarios

1. Routine Maintenance and Torque Calibration

During standard operation, the mill requires an inspection of the roller frame wear plates and fasteners every 2,000 hours.

-

Torque Verification: High-frequency vibration can lead to torque decay. Regularly verifying and re-tightening the 200MG41.11.09.77 bolt prevents loose connections that cause uneven wear on the grinding ring or roller misalignment.

2. Overhaul and Component Replacement

When the mill undergoes a complete teardown for a major overhaul, these bolts are core replacement items.

-

Mandatory Replacement: According to technical guidelines, new bolts must be used whenever the roller tires or liners are replaced.

-

Structural Safety: Since the hydraulic loading pressure is transmitted through the roller assembly to the foundation, the integrity of this bolt is vital to prevent catastrophic failures such as roller detachment.

IV. Selection and Maintenance Recommendations

To ensure optimal performance and safety, power plant engineers should follow these procurement and usage guidelines:

1. Integrated Spare Parts Procurement

For total system reliability, it is recommended to source the bolt alongside its synergistic components:

-

Guiding Elements: Guide Plate (20MG40.11.12.07.99) and Guide Block (20MG40.11.12.07.96).

-

Sealing Elements: Roller Skeleton Oil Seal ($340 \times 380 \times 20$).

2. Best Practices for Installation

-

Cleaning: Remove all debris and oxidation from the threads before assembly.

-

Torque Control: Always use a calibrated torque wrench to apply the exact OEM-specified force; both under-tightening and over-tightening can lead to fatigue failure.

-

Inspection Cycle: Align bolt inspections with the 1,000-hour grinding element wear measurement cycle.