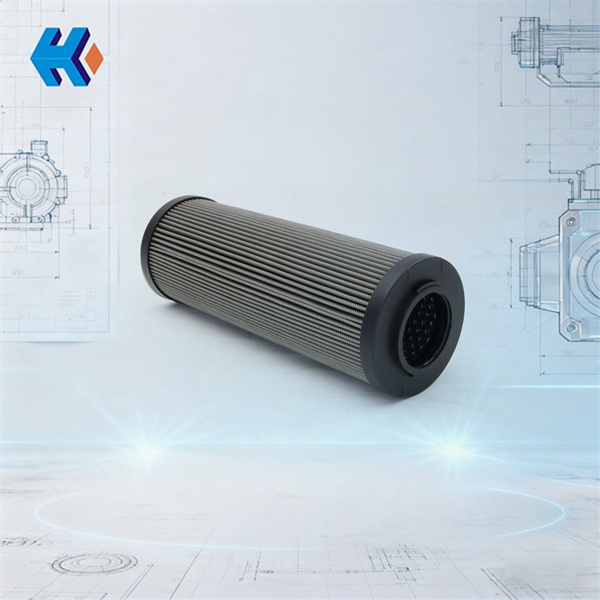

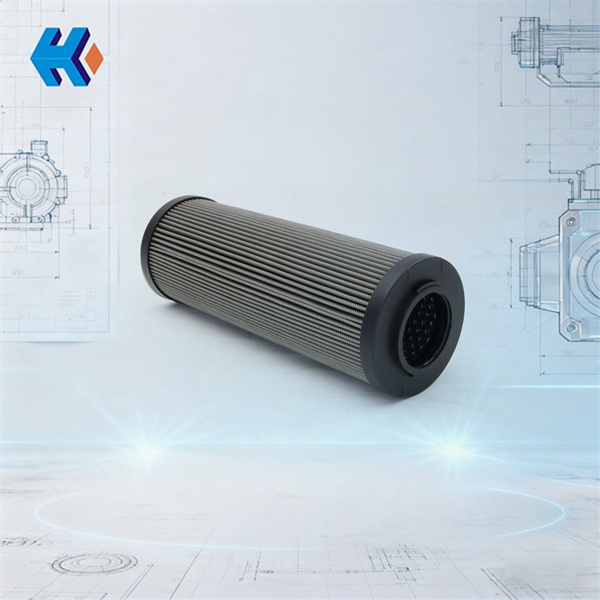

Replacement of 20MG30.20.03.02 Coal Mill Duplex Filter Element

In the maintenance of high-pressure oil systems for power station coal mills, replacing the duplex filter element is a high-frequency task. Today, using the Coal Mill Duplex Filter Element 20MG30.20.03.02 as an example, we will guide you on how to minimize hydraulic oil loss during replacement and ensure smooth air bleeding and stable system operation.

I. Minimizing Oil Loss: The "Switch + Depressurize" Method

The key to reducing oil waste lies in a precise two-step process. The duplex filter is designed with a standby housing and a changeover valve.

-

Switching: Before replacement, open the bypass valve on the standby side (located on the side of the valve body). Smoothly rotate the central changeover handle to the standby position, then tightly close the bypass valve. This ensures continuous oil supply and prevents unplanned shutdowns.

-

Drainage: Unscrew the oil drain plug at the bottom of the housing to be serviced. Allow the residual oil to flow into a collection tray or oil tank. This step recovers over 80% of the remaining oil—an essential move for both environmental protection and cost savings, as L-HM46 anti-wear hydraulic oil is expensive.

II. Standardized Installation of Element 20MG30.20.03.02

Precision is vital when installing the new element:

-

Cleaning: After removing the old element, clean the inner wall of the filter housing with a clean silk cloth or specialized flushing oil to prevent contaminants from entering the system.

-

Verification: When installing the HuaKai ShengRui 20MG30.20.03.02 filter element, confirm that the model number and flow direction markings match the original specifications.

Technical Note: This element utilizes high-dirt-holding glass fiber material with a filtration rating strictly controlled at 10μm. It is fully compatible with NAS 1638 Class 8 cleanliness requirements and has been field-proven for long life and high reliability in numerous coal mill projects.

III. The Final Critical Step: Air Bleeding

The most frequently overlooked step is properly bleeding the air. After installing the new element and tightening the top cover:

-

Do Not put it into immediate operation.

-

Loosen the air bleed plug (located at the top of the housing).

-

Slowly start the system pump or use the bypass to allow oil to gradually fill the housing.

-

Once a continuous stream of oil—free of bubbles—emerges from the bleed port, the air is fully exhausted. Quickly tighten the bleed plug.

Failure to do this can lead to pressure fluctuations, increased noise, and even malfunctions of the proportional valves.

Summary: Three Golden Rules

To ensure a successful replacement of the 20MG30.20.03.02 filter element, remember:

-

Switch the bypass first, then drain the residual oil.

-

Clean thoroughly and install accurately.

-

Bleed the air completely—patience over speed.

Following these steps protects your equipment, saves oil, and prevents unscheduled downtime caused by poor air venting.

For frontline maintenance personnel: Details determine success, and professionalism stems from standardization.

To further enhance the overall maintenance quality of the coal mill, we provide a variety of core supporting components in addition to the primary filter element 20MG30.20.03.02. These components cover critical sections of the coal pulverizing system, as detailed in the table below:

List of Core Supporting Components for Coal Mills

| Product Name | Model / Specification | Core Application & Purpose |

| Coal Mill Scraper | 20MG40.11.07.01.01 | Used for coal powder transport and scraping inside the mill; ensures uniform flow and prevents coal accumulation/clumping. |

| Roll Assembly Wear Plate | 20MG40.11.09.72J | Installed on critical contact surfaces of the roller assembly to resist coal powder erosion and extend service life. |

| Bowl Mill Scraper Device | 20MG40.11.07.01 | Specifically adapted for bowl-type medium-speed mills to achieve efficient coal scraping and distribution. |

| Sealing Plug | 20MG40.11.09.75J | Used for sealing oil chambers and cavities; prevents oil leakage and dust ingress to ensure high sealing reliability. |

| Roller Shaft | 20MG40.11.09.89j | The core transmission component of the roller assembly; transmits driving force to rotate the rollers for pulverization. |

| Journal (Roller) Bracket | 20MG40.11.09.98j | Carries the roller assembly; ensures installation precision and stability while absorbing impact loads during grinding. |

| Pivot Shaft Seat for Bracket | 20MG40.11.11.01 | Provides positioning and support for the bracket pivot shaft; ensures flexible rotation and dampens operational vibrations. |

| Bowl Mill Guide Block | 20MG40.11.12.07.95 | Provides guidance for internal moving parts to ensure they follow the predetermined path, preventing misalignment or jamming. |

| Pure Copper Washer | 20MG40.11.12.07-11 | Used for sealing connections; leverages the excellent ductility of copper to achieve precise seals against oil and gas leaks. |

| Separator Belt | 20MG40.11.15X-6 | Drives the coal mill separator to achieve classification of coarse and fine powder, ensuring output quality meets standards. |

| Protective Guard | 20MG42.11.09J | Shields exposed transmission and rotating parts to prevent accidental injury and block dust infiltration. |

HKZX-2026-01-05