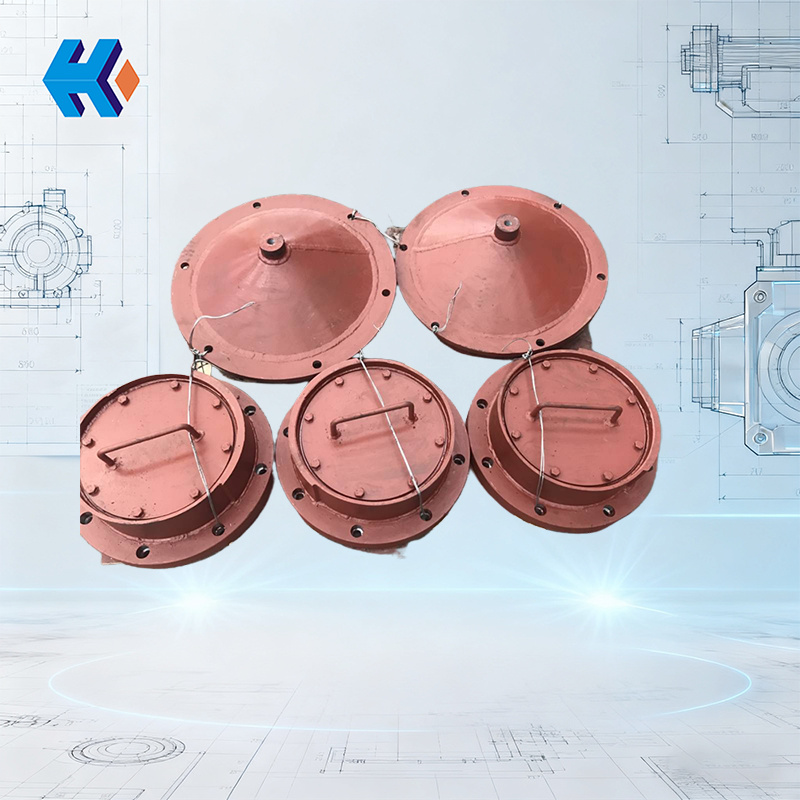

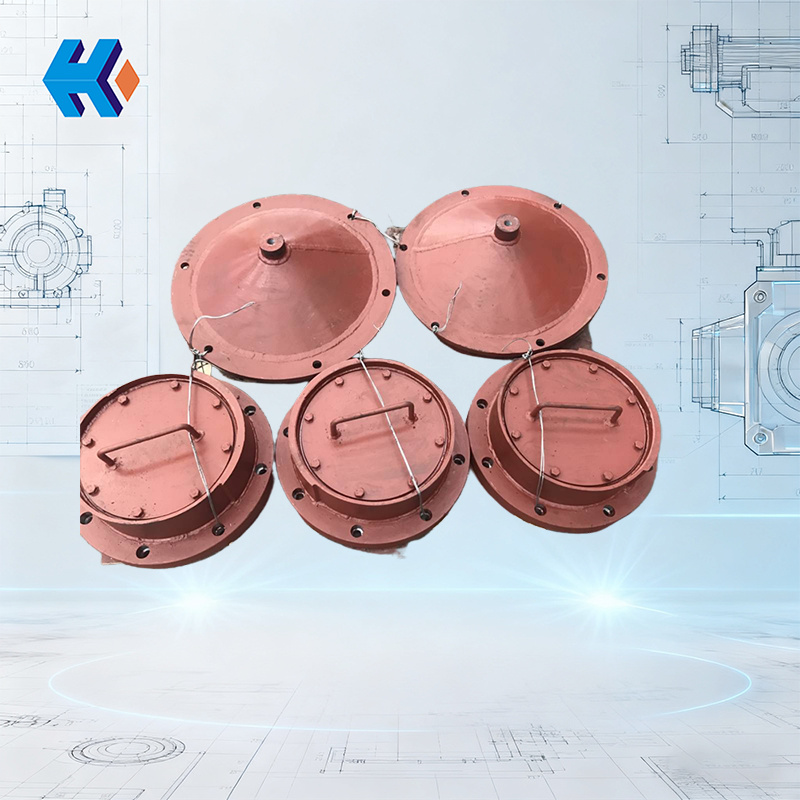

Protective Cover 20MG30.11.09.03J-Ensuring Structural Integrity of ZGM Coal Mill Roller Assemblies

In the operational framework of ZGM-type medium-speed roller coal mills, the roller assembly serves as the core grinding component. Its stability directly dictates the efficiency of the power plant's pulverizing system and the safety of the generating units. The Protective Cover (Part No. 20MG30.11.09.03J) is a critical safety and shielding component of the roller assembly, responsible for isolating moving parts, blocking dust infiltration, and ensuring maintenance safety.

1. Product Overview

The Protective Cover 20MG30.11.09.03J is specifically engineered for ZGM series medium-speed mills. It works in conjunction with Wear Plates (138MG40.11.09.72j/71j) and the Roller Breather (20MG40.11.09.01j) to form a comprehensive protection and sealing system.

Key Design Features:

-

Material: Constructed from Q235A carbon steel, offering excellent weldability, mechanical strength, and impact resistance.

-

Structure: Features a horizontally split design with a mid-section flange connection. This allows for rapid disassembly and assembly during maintenance without removing the entire roller assembly.

-

Primary Functions:

-

Isolation: Protects internal bearings and lubrication systems from abrasive coal dust.

-

Safety Barrier: Prevents personnel from contacting moving parts during operation and maintenance.

-

2. Technical Features and Advantages

-

Stress-Relief Annealing: To prevent structural deformation during operation, the cover undergoes a strict post-weld stress-relief process. Following JB/T 6046 and GB50661-2011 standards, it is heated to 600–650°C, held for 2–4 hours, and slowly cooled. This ensures long-term dimensional stability.

-

Optimized Sealing: The flange connection surfaces are precision-machined to work seamlessly with the breather and oil seal bracket, minimizing the risk of lubricant leakage and external contamination.

-

Precise Compatibility: Dimensions are calibrated to fit ZGM installation interfaces perfectly, ensuring no interference with the upper and lower pull rods (21MG40.11.13.99/96).

3. Core Spare Parts Synergy Table

The following table details the interaction between the Protective Cover and other essential roller assembly components:

| Component Name | Part Number | Primary Function | Synergy with Cover 20MG30.11.09.03J |

| Protective Cover | 20MG30.11.09.03J | Isolates moving parts; blocks dust; ensures safety. | Core protective component; provides the foundation for other shields. |

| Wear Plate (I) | 138MG40.11.09.72j | Resists coal dust erosion. | Reduces dust scouring on the cover’s surface, extending its lifespan. |

| Roller Breather | 20MG40.11.09.01j | Balances pressure; prevents grease leakage. | Works with the cover to optimize sealing and protect the lubrication system. |

| Graphite Carbon Ring | 299MG41.11.06.98 | Shaft-end sealing against media leakage. | Forms multi-stage sealing with the cover to upgrade the protection level. |

| Oil Seal Bracket | 20MG43.11.09.37 | Fixes oil seals; ensures sealing stability. | Provides auxiliary sealing support to the cover, enhancing reliability. |

4. Application and Maintenance Scenarios

The Protective Cover 20MG30.11.09.03J is widely used in thermal and nuclear power plants. In the harsh environment of a ZGM mill—characterized by high vibration and dense coal dust—this cover is a "high-check" item during overhauls.

Maintenance Indicators for Replacement:

-

Visible deformation or weld cracking.

-

Damage to the flange sealing surface.

-

Wear exceeding safety limits, which could lead to bearing contamination or grease pollution.

Using high-quality, standardized covers significantly shortens the maintenance cycle during roller tire replacements (e.g., 20MG42.11.09) and reduces unplanned outages.

5. Selection and Procurement Recommendations

For power station engineers and procurement decision-makers, it is advised to:

-

Verify Material Standards: Ensure the use of Q235A steel with full stress-relief annealing reports.

-

Confirm Dimensions: Match specific ZGM model numbers to avoid assembly interference.

-

One-Stop Sourcing: Prioritize suppliers who can provide the full kit (cover, wear plates, and breathers) to ensure 100% component synergy and reduce procurement costs.

HKZX-2026-01-28