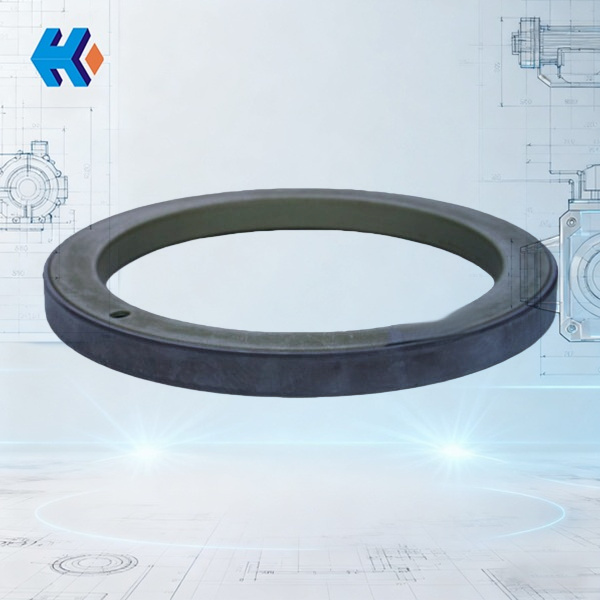

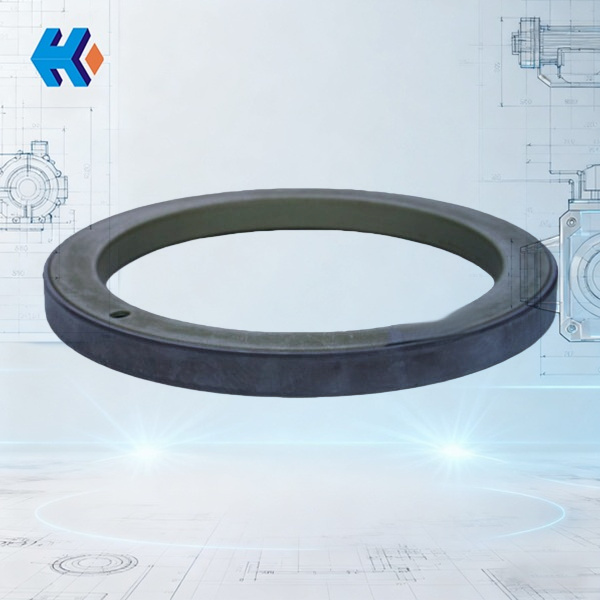

Oil Seal Bracket 20MG43.11.09.37: Core Positioning Component for ZGM Medium-Speed Coal Mill Sealing Systems

In the sealing system of ZGM-type medium-speed roller coal mills, the Oil Seal Bracket (Part No. 20MG43.11.09.37) serves as the core positioning and load-bearing component. It directly determines the installation precision and operational stability of the entire sealing assembly.

Operating under harsh conditions—including internal oil temperatures up to 110°C, coal dust infiltration, and pressure fluctuations—this bracket provides a precise positioning reference for components like the roller oil seal and breather. It transmits loads and ensures sealing synergy, making it a critical spare part during power plant maintenance. High-quality brackets effectively extend the service life of the sealing system and reduce maintenance frequency.

1. Product Overview

The Oil Seal Bracket 20MG43.11.09.37 is specifically designed for the roller-and-bowl ZGM series coal mills. It is installed at the roller shaft end cap (refer to specific equipment drawings for exact alignment) and works in tandem with the Breather (20GM20.11.09.01J) and Roller Oil Seal (20MG20.11.09.92J).

Key Functions:

-

Precision Alignment: Achieves coaxial positioning of the seal with the roller shaft (tolerance within 0.02mm), preventing seal failure caused by eccentric operation.

-

Load Distribution: Transmits radial and axial loads, relieving pressure on the sealing elements during high-vibration operation.

-

Sealing Air Integration: Works with the sealing air system to prevent coal dust from entering and damaging the bearings and seals.

The bracket is manufactured from high-quality carbon steel, chosen for its mechanical strength and thermal stability, ensuring it does not deform under the 110°C operating environment.

2. Technical Features and Advantages

-

Superior Material Stability: Treated with CNC precision machining and anti-corrosion coating, the carbon steel body maintains structural integrity despite temperature fluctuations.

-

High Coaxiality: With alignment errors controlled within 0.02mm, it minimizes lip wear on the oil seal, significantly boosting the longevity of consumables.

-

Maintenance-Friendly Design: The modular structure allows for rapid disassembly and assembly via standardized bolts. Maintenance personnel can replace seals or carbon rings without a full teardown of the roller assembly.

-

Synergetic Performance: Pre-configured assembly gaps optimize sealing air flow, creating a "clean ring" seal that repels dust.

3. Core Spare Parts Synergy Table

The following table outlines how the Oil Seal Bracket integrates with other critical components in the ZGM mill sealing system:

| Component Name | Part Number | Primary Function | Synergy with Bracket 20MG43.11.09.37 |

| Oil Seal Bracket | 20MG43.11.09.37 | Positioning, load transmission, installation base. | Acts as the foundational anchor for all other sealing components. |

| Roller Oil Seal | 20MG20.11.09.92J | Blocks dust and seals lubrication oil. | Relies on the bracket for precise centering to prevent eccentric wear. |

| Breather | 20GM20.11.09.01J | Balances oil chamber pressure. | Mounted via the bracket to ensure stable air pressure within the oil cavity. |

| Carbon Sealing Ring | 300MG31.11.06.93 | Frame sealing and wear compensation. | Works with the bracket to form multi-stage sealing against air pressure. |

| Elastic Sleeve | 300MG31.11.02.96 | Vibration buffering. | Dampens shocks to protect the bracket's positioning accuracy. |

4. Application Scenarios

This bracket is widely utilized in the roller shaft end sealing systems of ZGM series medium-speed mills within thermal and nuclear power plant pulverizing systems.

During major overhauls or seal replacements, the 20MG43.11.09.37 bracket must be inspected for:

-

Structural Integrity: Checking for cracks or deformation due to fatigue.

-

Positioning Accuracy: Ensuring bolt holes and mounting surfaces are not worn beyond tolerance.

-

Connection Security: Checking for stripped threads or loose fittings.

In positive-pressure ZGM mills, the sealing air pressure must remain ≥2kPa higher than the primary air pressure. The precision of this bracket ensures the sealing air forms an effective barrier, cooling the roller while preventing coal dust leakage.

HKZX-2026-01-28