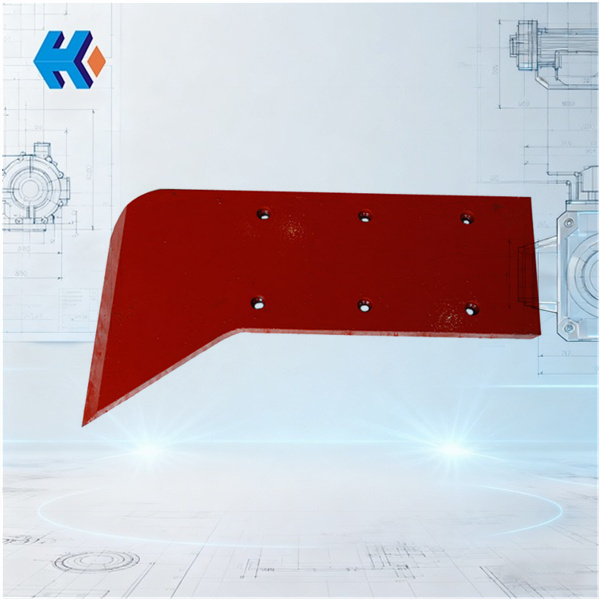

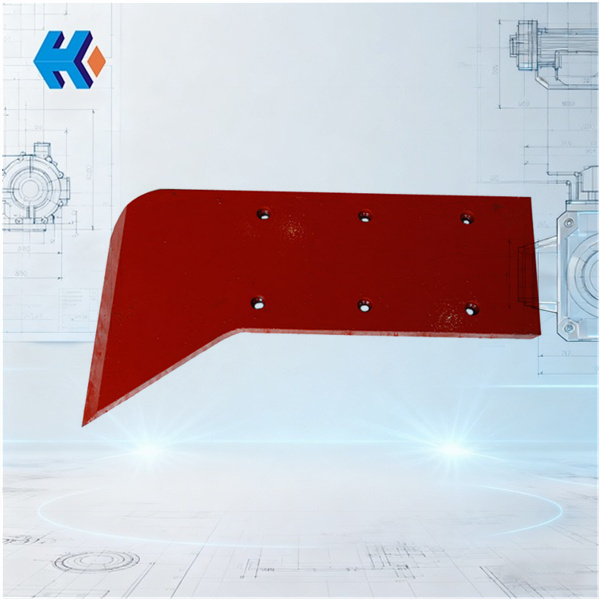

Technical Specifications: 200MG41.11.09.71 Roller Assembly Wear Plate

The Wear Plate 200MG41.11.09.71 is a specialized protective spare part designed for the roller assembly of ZGM95G medium-speed pulverizers. Positioned at the junction of the roller and the pressure frame, its core function is to shield critical components—such as the Roller Bracket (20MG40.11.09.98) and Shaft Sleeve (20MG50.11.09.84J)—from the abrasive flushing of coal dust and impurities. Additionally, it provides structural support for the Radial Oil Seal (38042020), optimizing the local sealing environment.

I. Product Overview

In a ZGM95G pulverizer, the roller is installed at a 15° tilt between the grinding table and the pressure frame. Operating at temperatures up to 110°C, the assembly faces constant kinetic impact from coal particles. The wear plate serves as the first line of defense in the pulverizer's internal anti-wear system.

-

System Integration: Works alongside the Liner (20MG53.11.08.98J) and Scraper Device (313MG31.11.07.01).

-

Protection Focus: While liners protect the grinding surface and scrapers clear pyrites, this wear plate focuses specifically on the high-wear zones of the roller assembly.

II. Technical Features and Advantages

| Feature | Technical Specification | Operational Benefit |

| Base Material | Q235 Carbon Structural Steel (GB/T 700-2006) | High toughness and weldability; maintains structural stability at 110°C without brittle fracture. |

| Hardfacing Layer | High-Chromium Alloy (Open-arc welding) | Hardness of HRC55–HRC65; improves wear resistance by 5–10 times compared to standard steel. |

| Hardfacing Thickness | 4mm – 6mm | resist extreme particle erosion. |

| Surface Treatment | Phosphate Rust-proofing (Non-working face) | Salt spray resistance48 hours; protects against corrosion in humid pulverizer environments. |

| Manufacturing Precision | CNC Cutting & Grinding | Tolerances within 0.03mm; ensures a "drop-in" fit with the roller bracket and oil seals. |

Advanced Hardfacing Process

The working surface utilizes an automated hardfacing process with optimized parameters:

-

Wire Diameter: 2.8mm

-

Current/Voltage: 300A / 30V

-

Cooling Technology: Pressure water cooling is applied to accelerate solidification, maximizing hardness while minimizing welding deformation.

-

Stress Relief: The fine, dispersed stress-relief cracks in the cladding layer prevent the hardfacing from delaminating under thermal cycling.

III. Application Scenarios

1. Routine Inspection (Every 6,000 Operating Hours)

During scheduled inspections, the wear plate should be checked via the roller inspection door.

-

Replacement Criteria: If the cladding wear exceeds 2mm or if the base material shows deformation, immediate replacement is required.

-

Synergy Check: Inspect the Sealing Ring (20MG50.11.09.92J) and Breather (20MG40.11.09.01J) concurrently to ensure the entire assembly is airtight.

2. Planned Overhaul (30,000-Hour Major Cycle)

During a total plant overhaul, the wear plate is typically replaced alongside the Grinding Roller Tires and Scrapers (20MG33.11.07).

-

Installation Note: After removing the Protective Cover (20MG40.11.09.03), ensure the mounting gap between the plate and the shaft sleeve meets standard clearances to prevent friction with the Radial Oil Seal (38042020).

3. Emergency Repair & Fault Response

In the event of a sealing leak or abnormal vibration caused by coal dust ingress, the high compatibility of this part allows for rapid restoration.

-

Efficiency: Standardized mounting holes allow for direct bolting without on-site machining, typically reducing repair time by over 50% (approx. 4 hours for a full swap).

-

Non-Interference: The installation does not interfere with the Upper Pull Rod (21MG40.11.13.99) or Lower Pull Rod (21MG40.11.13.96), allowing for parallel maintenance tasks.

IV. Summary of Technical Parameters

| Parameter | Value / Standard |

| Target Model | ZGM95G Medium-Speed Pulverizer |

| Tensile Strength | 375 – 500 MPa |

| Hardness (Cladding) | 55 - 65 HRC |

| Surface Cleanliness | Oil-free, no burrs |

| Mounting Hole Precision | 0.02mm |

HKZX-2026-01-23