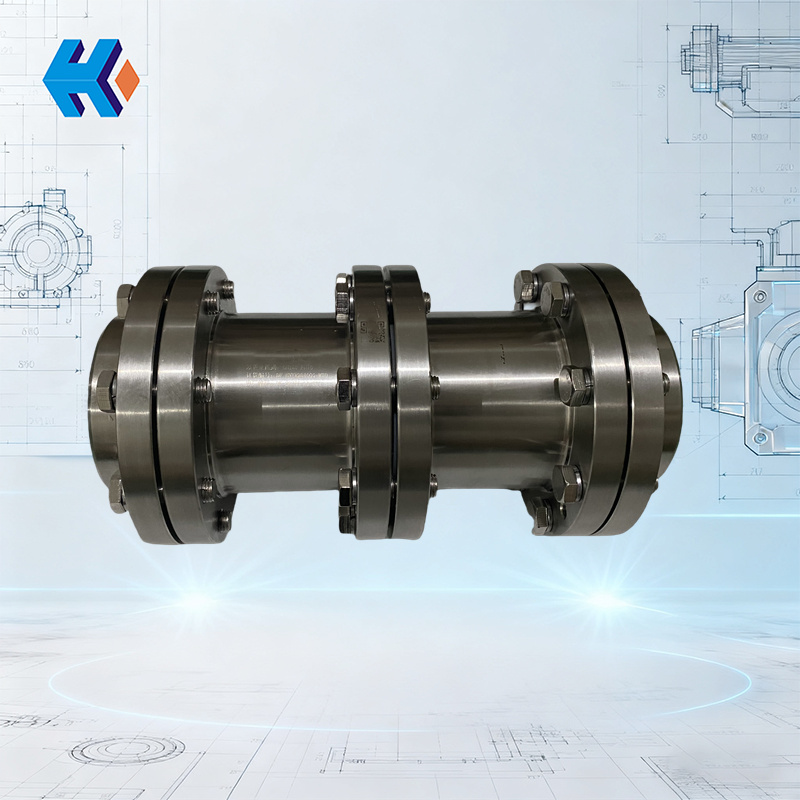

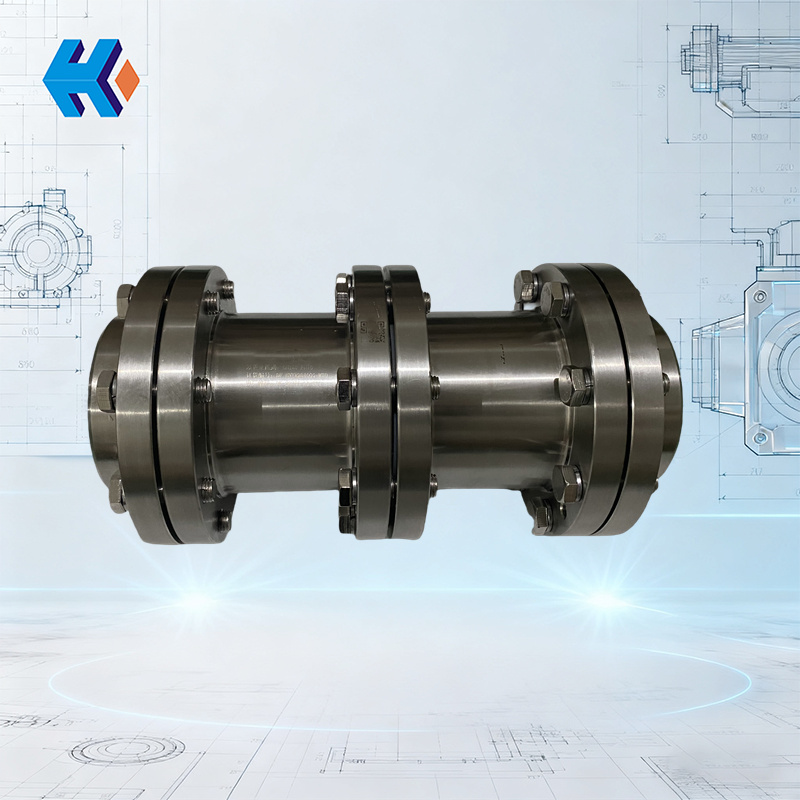

Double-Flap Check Valve for Steam Turbine

A double-flap check valve is a critical accessory in the steam turbine system used to control the direction of media flow. It acts like a "one-way gate," ensuring the media flows in the specified direction and preventing backflow that could cause equipment failure. It plays a crucial role in various parts of the steam turbine's oil and water systems. Understanding its working characteristics and maintenance knowledge is essential for ensuring the unit's stable operation.

I. The Core Function of the Double-Flap Check Valve

In the various piping systems of a steam turbine, the unidirectional flow of media is vital. For example, in a lubrication oil system, if the oil flows backward, it could lead to an interruption of oil supply to the bearings, causing bearing tiles to burn out. In a cooling water system, water backflow could affect the cooling effect or even damage the pump body. The core function of the double-flap check valve is to prevent media backflow. When the media flows in the normal direction, it can open smoothly. If a backflow trend appears, the valve will close quickly, cutting off the path for media to flow in the reverse direction, thereby protecting the safety of the related equipment.

II. Working Principle

The working principle of the double-flap check valve is based on the balance between the thrust of the media flow and the valve's own gravity. The valve's interior has two symmetrical "flaps", which is where the name "double-flap" comes from.

When the media flows in the specified direction, the thrust of the media overcomes the gravity of the flaps, pushing the two flaps open to form a flow passage, and the media passes through smoothly. When the media attempts to flow backward, the reverse pressure acts on the flaps. Coupled with the flaps' own gravity, the two flaps will close quickly and seal tightly against the valve seat, thus blocking the backflowing media. This double-flap structure allows the valve to close more quickly and seal more tightly. Compared to a single-flap check valve, it has stronger resistance to oil hammer.

III. Structural Composition

The double-flap check valve is mainly composed of the following parts:

- Valve Body: The outer casing of the valve that connects the front and rear pipes and provides installation space for the internal components. It is usually made of pressure-resistant materials such as cast iron or cast steel.

- Double-Flap Valve Discs: The two symmetrical flap-shaped valve discs are the core sealing components. The material is selected based on the media's characteristics, such as using wear-resistant alloys in oil systems or stainless steel in water systems, to ensure good sealing and wear resistance.

- Valve Seat: Works with the valve discs to form the sealing surface. The surface is precision machined to ensure the sealing when the valve discs are closed.

- Shaft: The valve discs are connected to the valve body through a shaft, allowing the discs to rotate flexibly to open and close. The shaft must have good wear resistance and flexibility.

IV. Maintenance and Inspection Points

To ensure the reliable operation of the double-flap check valve, daily maintenance and regular inspections should focus on the following points:

- Regular Cleaning: Since the media may contain impurities, dirt may accumulate between the valve discs and the valve seat after long-term operation, affecting the sealing. Regular disassembly and cleaning are necessary to remove impurities and ensure a smooth sealing surface.

- Sealing Performance Check: The valve's sealing can be assessed by observing changes in pipe pressure or leakage after it is closed. If leakage is found, the sealing surface needs to be ground or the valve discs and seat need to be replaced.

- Flexibility Check: Check if the valve discs rotate flexibly and if there is any sticking.

- Appearance Check: Check the valve body for cracks and corrosion, and ensure the connecting flanges are tight to guarantee the overall structural integrity of the valve.

V. Custom Fabrication per Drawings

We provide precision manufacturing of steam turbine double-flap check valves strictly in line with your technical drawings. Our production fully complies with your specified requirements: including valve body materials, valve disc materials, precision machining of key parts, and pressure rating adaptation.

Prevent Media Backflow—Protect Your Turbine Equipment!

Our double-flap check valves offer fast closing, tight sealing, and strong oil hammer resistance. Contact us now for a customized quote, sealing performance test reports. We guarantee on-time delivery and after-sales maintenance guidance to keep your turbine's oil systems running safely.