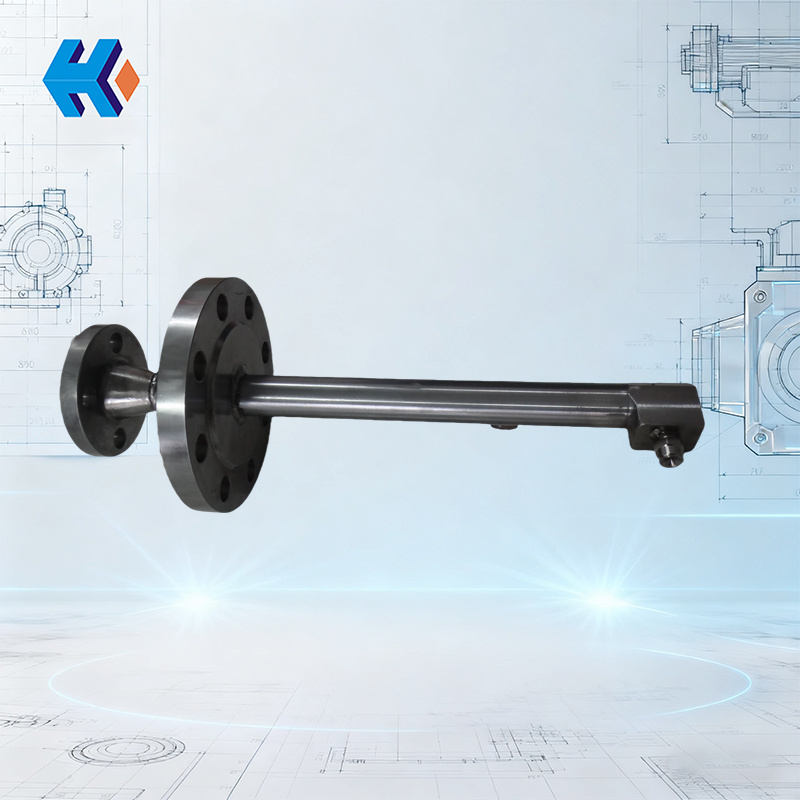

Turbine LP Cylinder Gland Seal Attemperator Nozzle

The Turbine LP Cylinder Gland Seal Attemperator Nozzle is a critical, high-precision component engineered to optimize the performance and safety of a power plant's turbine low-pressure (LP) cylinder gland seal system. By precisely controlling the volume of injected spray water, it accurately manages the gland seal steam temperature, preventing costly equipment damage from overheating and ensuring the turbine maintains peak operational efficiency. Manufactured from advanced corrosion-resistant and high-temperature alloys, it guarantees exceptional longevity and reliability in demanding service environments.

Product Features

- Superior Atomization & Efficient Cooling: A specialized nozzle geometry ensures the spray water is fully atomized into ultra-fine particles. This maximizes the surface contact area with the steam, facilitating rapid, uniform, and highly effective temperature reduction.

- Precise Flow Modulation: The design allows for flexible adjustment of the spray volume, maintaining the gland seal steam temperature within the narrow optimal range. This precise control minimizes energy consumption and significantly extends the lifespan of associated turbine components.

- High-End Material Construction: The main body is crafted from high-grade stainless steel for superior resistance to corrosion and scaling. Internal control components undergo specialized heat treatment and surface hardening processes to deliver unmatched wear resistance against high-velocity steam and water mixtures.

Processing According to Drawings

We adhere to a strict, multi-stage manufacturing protocol to ensure every nozzle meets the most stringent design and performance specifications as outlined in your engineering drawings.

- Precision CNC Machining: Components are manufactured exclusively using multi-axis Computer Numerical Control (CNC) machinery to achieve extremely tight tolerances on bore diameters, spray angles, and critical flow passages. This precision is essential for guaranteeing repeatable and accurate flow control.

- Material Traceability and Certification: All raw materials, including stainless steel and specialty alloys, are sourced with complete material traceability to ensure full compliance with industry standards. Certified Material Test Reports are available on your request.

- Dimensional and Performance Verification: Each nozzle undergoes comprehensive inspection. Furthermore, critical nozzles are subjected to flow performance testing to verify that the specified spray pattern and flow rate are achieved under simulated operating pressures.

- Quality Assurance: A rigorous Quality Assurance (QA) program, oversees every production phase, from initial material receipt to final packaging, guaranteeing zero-defect delivery.

Why Choose Our Nozzle?

This nozzle isn't just a replacement part—it's an upgrade to your turbine's reliability and efficiency. Choosing our product is a strategic decision that delivers quantifiable returns. Leverage our decades of experience in turbine component optimization. We provide comprehensive technical documentation and dedicated support to ensure flawless installation and long-term performance monitoring.

Contact our sales team today for a custom consultation and a no-obligation quote.