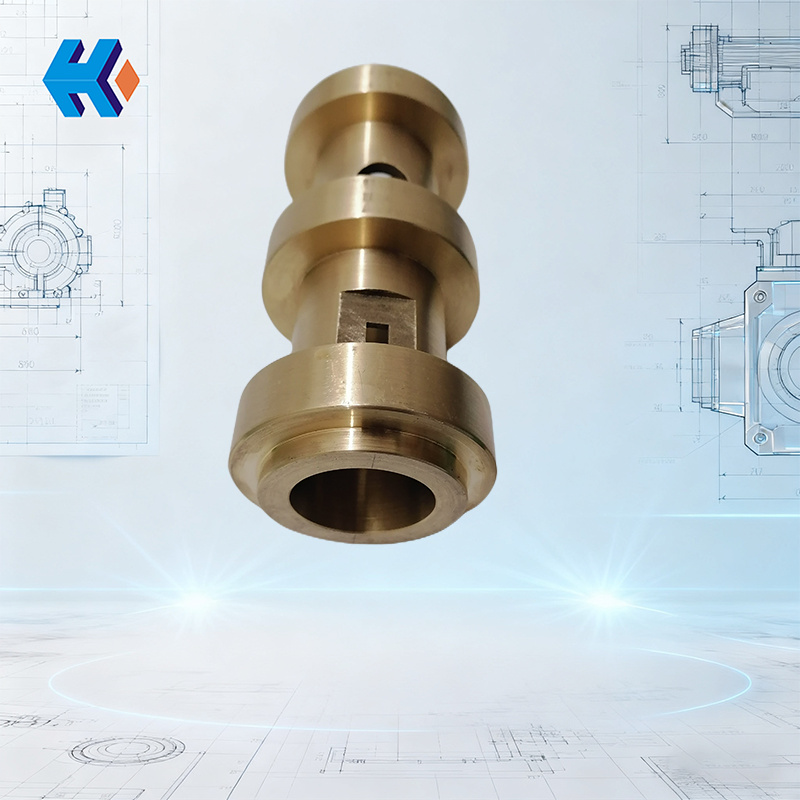

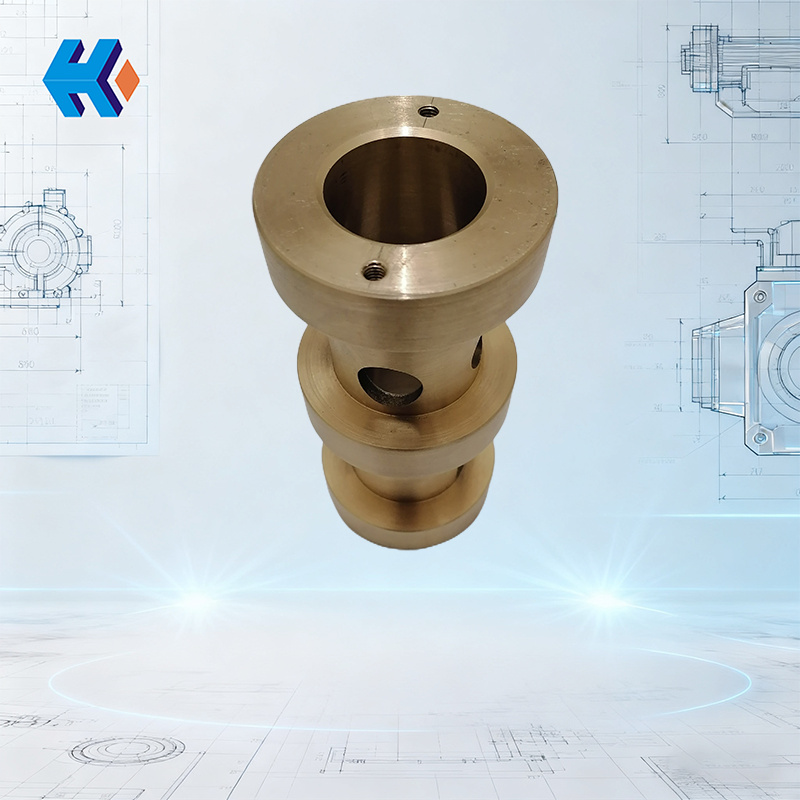

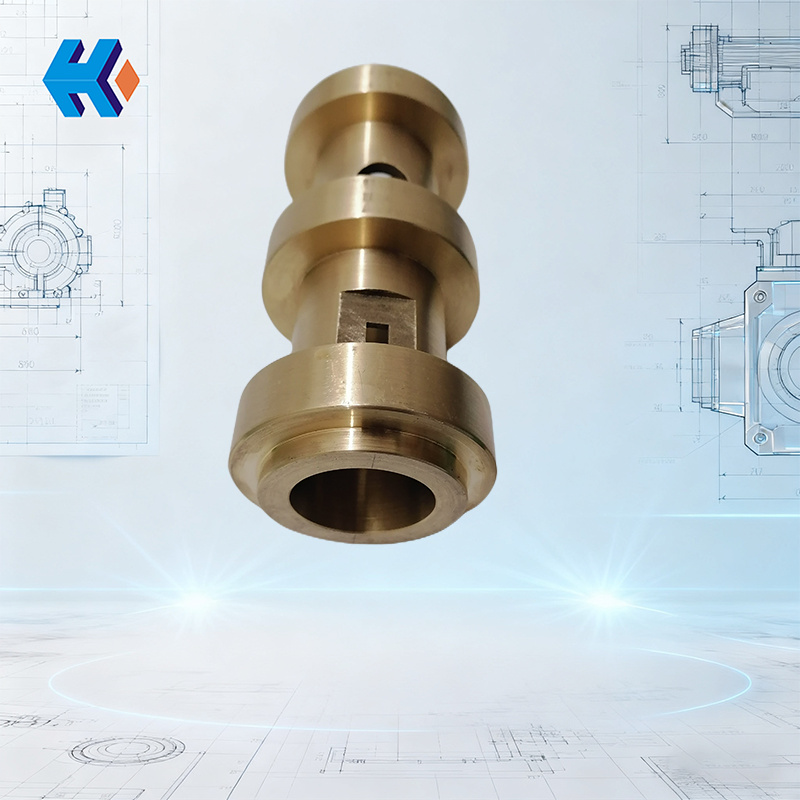

Steam Turbine Intermediary Pressure Valve Sleeve

Product Overview

The steam turbine intermediary pressure valve sleeve is a key component in the steam turbine's regulating system. It is mainly used for the precise control and sealing of the steam turbine's intermediary valve. During the steam turbine's operation, it performs the important functions of flow regulation, pressure control, and media isolation. This component, through precise structural design and high-quality material manufacturing, ensures the stable and efficient operation of the steam turbine under various working conditions. It is one of the core accessories that guarantees the unit's safety and economy.

Product Structure and Features

Precision Structural Design

- Uses a streamlined internal channel design to reduce media flow resistance and improve energy conversion efficiency.

- The mating surface undergoes ultra-precision machining to ensure a perfect fit with the valve core for precise regulation.

- A reasonable wall thickness and reinforcing rib design improve overall structural strength and fatigue resistance.

High-Quality Material Selection

- The main body is made of high-strength alloy steel (such as 2Cr13, 12Cr1MoV, etc.), which has excellent high-temperature and high-pressure resistance.

- The key mating surfaces can be surface-hardened (such as nitriding, chromium plating) as needed to improve wear resistance and corrosion resistance.

- Heat-resistant alloy materials can be selected for special conditions to adapt to long-term operation in a high-temperature and high-pressure steam environment.

Performance Advantages

- Working Temperature Range: -20°C to 550°C (special materials can extend to 650°C).

- Design Pressure: ≤30MPa, meeting the working pressure requirements of various steam turbines.

- Excellent Sealing Performance: Leakage rate is ≤0.01% of the rated flow.

- Long Service Life: Can reach more than 80,000 hours with normal maintenance.

Scope of Application

This product is suitable for various thermal power plants, nuclear power plants, and steam turbines for industrial use, specifically including:

- Steam turbines for main power generation units of 300MW, 600MW, 1000MW, etc.

- Extraction-condensing and back-pressure industrial steam turbines.

- Steam turbines for combined-cycle gas-steam units.

- Waste heat utilization steam turbine systems.

Product Advantages

- High-Precision Machining: Uses precision machining equipment such as CNC lathes and grinders to ensure dimensional tolerances are controlled within ±0.005mm.

- Strict Quality Control: Each product undergoes multiple quality inspection procedures, including non-destructive testing, dimensional verification, and pressure testing.

- Customization Service: Can be precisely copied and custom-produced based on drawings or samples provided by the customer.

- Comprehensive Adaptability: Compatible with mainstream steam turbine brands at home and abroad.

Installation and Maintenance

- The surface must be cleaned before installation to remove oil and impurities.

- Avoid collisions with the mating surface during installation and it is recommended to use special tools for assembly.

- Regularly check for wear. It is recommended to perform an inspection every 10,000 hours of operation.

- Store in a moisture-proof and dust-proof manner to avoid long-term exposure to harsh environments.

Custom Fabrication per Drawings

We provide precision manufacturing of steam turbine intermediary valve sleeves strictly according to your technical drawings. Our production fully complies with your specified requirements: including material selection (2Cr13, 12Cr1MoV, or special heat-resistant alloys), dimensional tolerances (controlled within ±0.005mm), surface treatments (nitriding, chromium plating), and performance parameters (design pressure ≤30MPa, working temperature up to 650°C). We also adhere to industry standards and conduct non-destructive testing, pressure testing, and sealing performance verification to ensure each valve sleeve matches your turbine's intermediary valve perfectly, whether for maintenance replacement or new unit assembly.

Ensure Precise Steam Regulation—Choose Our Intermediary Valve Sleeve!

Our valve sleeves deliver high-temperature/pressure resistance, tight sealing, and long service life. Contact us now for a customized quote, technical consultation on material selection. We guarantee on-time delivery and after-sales support to keep your turbine's regulating system running stably and efficiently.