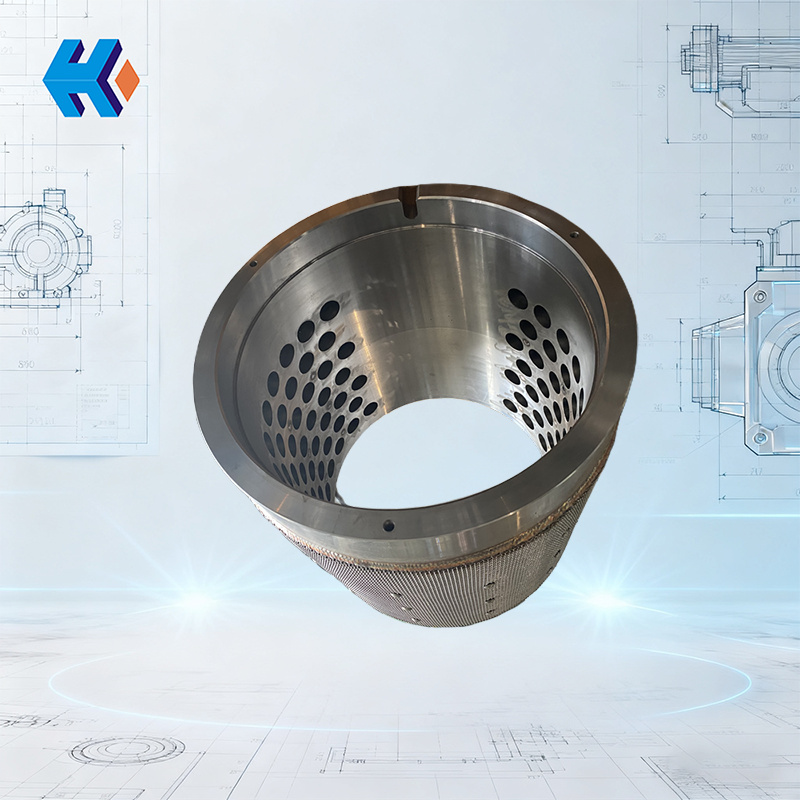

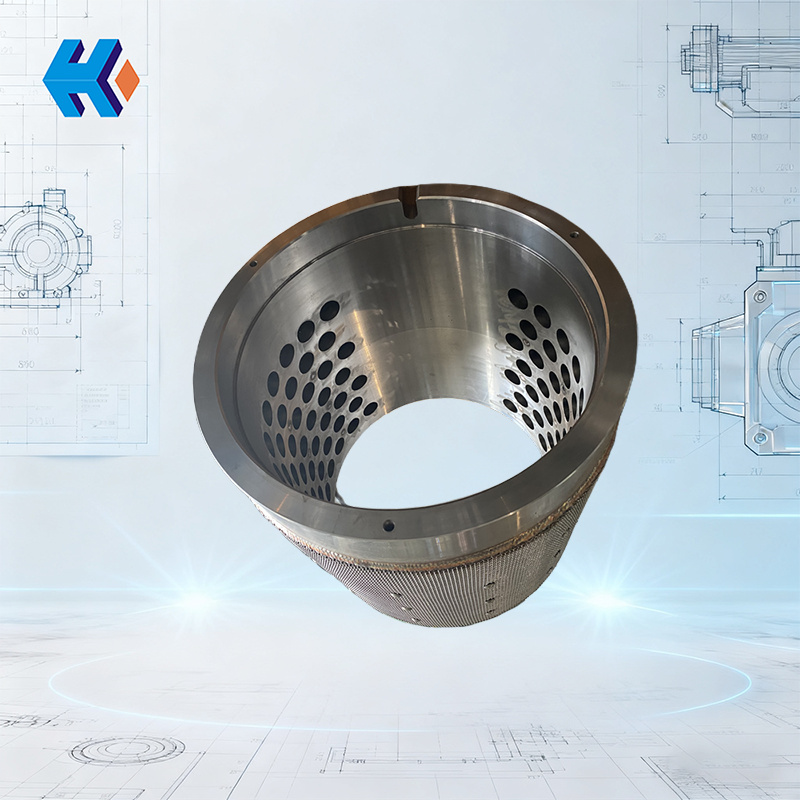

High-Pressure Steam Strainer for Steam Turbine

The turbine high-pressure steam strainer is a vital protective component integrated into steam supply systems of thermal power plants, nuclear power units, and industrial turbines. Installed upstream of the turbine's steam inlet, it acts as the "first line of defense" for the turbine core. Its primary role is to filter out solid impurities, suspended particles, and condensed water droplets from the high-pressure steam stream before it enters the turbine. Unfiltered contaminants can cause severe abrasion to turbine blades, blockage of steam nozzles, and corrosion of internal components—directly compromising the turbine's operating efficiency, shortening its service life, and even triggering unexpected shutdowns. By ensuring clean, dry steam supply, this strainer effectively safeguards the turbine's core parts and maintains stable, long-term system operation.

Product Features

- High-Efficiency Filtration Performance: Adopts a multi-layer stainless steel mesh structure with gradient filtration precision, which can efficiently capture impurities, solid particles, and condensed water droplets in the steam. The mesh’s aperture is scientifically optimized based on different turbine power grades and steam parameters—ensuring over 99% filtration efficiency while keeping the pressure drop below 0.05 MPa, avoiding unnecessary energy loss in the steam pipeline.

- Superior High-Temperature and High-Pressure Resistance: Constructed from high-quality heat-resistant alloy steel, it can stably operate in extreme environments where steam temperature reaches up to 600°C and pressure exceeds 20 MPa. The material undergoes professional solution annealing and stress relief treatment, which significantly enhances its tensile strength, impact toughness, and corrosion resistance—prolonging the strainer's service life under normal operating conditions.

- User-Friendly Rational Structural Design: The strainer's overall structure is tailored to match turbine operating characteristics: its cylindrical or conical inner cavity design optimizes steam flow path, eliminating flow dead zones and ensuring uniform filtration. It is equipped with a quick-release flange connection and a detachable filter element—allowing maintenance personnel to complete filter element replacement within 30 minutes without disassembling the entire pipeline. Additionally, a dedicated condensed water drain port at the bottom prevents water accumulation and avoids secondary pollution caused by water vapor mixing.

Custom Fabrication per Drawings

We provide precision manufacturing of turbine high-pressure steam strainers strictly in accordance with your technical drawings and specifications. Our production process strictly complies with dimensional tolerances, material grade requirements, and filtration efficiency standards. We support customization for special parameters (such as non-standard pressure rating, mesh precision, or connection type) to perfectly match your turbine system's unique operating conditions.

Protect Your Turbine—Choose Our High-Pressure Steam Strainer!

Our high-performance steam strainers effectively prevent turbine component wear and system failures. Contact us now for a free technical consultation, customized quotation. We guarantee on-time delivery and after-sales maintenance support to meet your project's schedule and operational needs.