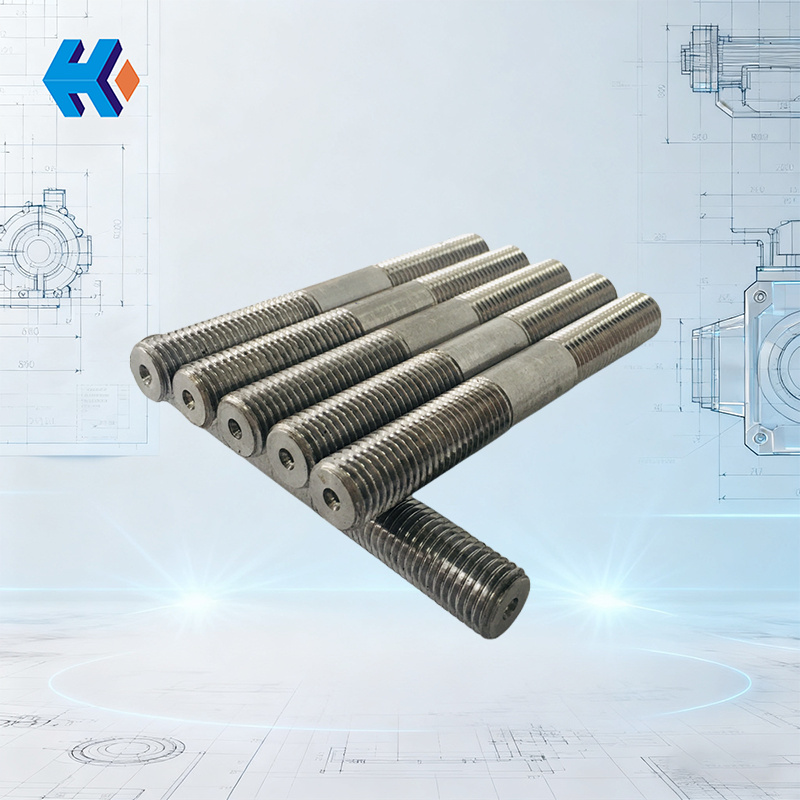

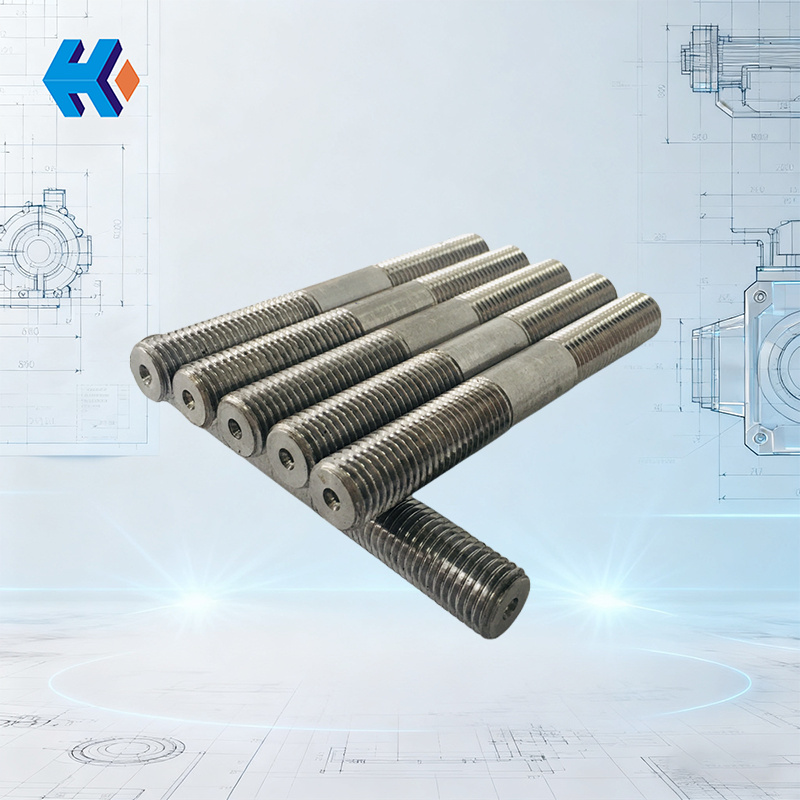

Steam Turbine High-Temperature Double-Ended Stud Bolt

Product Overview: Engineered Fastening for Extreme Conditions

The High-Temperature Stud Bolt is the core structural fastener essential for maintaining the integrity of the steam turbine's main connection structures. These specialized fasteners are indispensable in high-temperature, high-pressure zones, including the horizontal split flanges of high and medium-pressure cylinders, main steam valves, control valves, end covers, and steam inlet pipes.

The entire product series is forged from premium high-temperature alloy steel, meticulously selected to deliver superior high-temperature strength, excellent creep resistance, reliable relaxation resistance, and extended fatigue life. Critically, these stud bolts are engineered to maintain a stable, reliable pre-tightening force even under long-term exposure to extreme conditions (e.g., temperatures above 600°C and high-stress loads), ensuring leak-free, stable operation.

Main Materials and Operating Conditions: Alloy Selection for Specific Demands

The choice of alloy steel is precisely matched to the specific thermal and mechanical stresses of the turbine application, ensuring optimal performance and cost-effectiveness:

| Material (Alloy Steel) | Key Properties & Advantages | Typical Application Temperature | Primary Applications |

|---|---|---|---|

| 25Cr2MoVA | Features high high-temperature strength and excellent comprehensive mechanical properties, offering a balance of performance and reliability. | ≤580℃ | Critical connections on high-pressure cylinder split flanges and main steam valves where temperatures approach operating limits. |

| 35CrMoA | Known for its good tempering properties and is moderately priced, providing a robust, cost-effective solution. | ≤480℃ | Used for flange connections on medium-pressure cylinders and various auxiliary system components where temperatures are lower but still require high strength. |

| 20Cr1Mo1VNbTiB | A new generation heat-resistant steel boasting particularly strong creep resistance—the ability to resist deformation under sustained mechanical stress at high temperatures. | ≤600℃ | The preferred choice for the most demanding high-temperature bolts in modern supercritical and ultra-supercritical turbine units. |

Engineering Focus: Creep and Relaxation Resistance

The primary challenge in turbine bolting is managing creep and stress relaxation.

- Creep Resistance: This refers to the alloy's ability to resist permanent deformation (plastic flow) that occurs over time under constant stress at high temperatures. High creep resistance ensures the bolt maintains its shape and integrity.

- Relaxation Resistance: This is the bolt's ability to resist the *loss* of the initial pre-tightening force (the preload) over time due to high temperatures and stress. A high relaxation resistance is crucial for maintaining the flange sealing integrity and preventing steam leaks, making the selection of high-performance alloys vital.