Oil Seal Rings in Large Generator Sets

The oil seal ring is a non-negotiable component in large generator sets, functioning as a primary mechanical barrier to prevent lubricating oil leaks and safeguard internal precision parts from contamination, directly contributing to machine longevity and environmental protection.

1. Functions of Oil Seal Rings

- Preventing Lubricating Oil Leaks: The main function is to ensure that lubricating oil remains within the equipment, particularly at bearing housings. This reduces oil waste and avoids environmental pollution caused by leaks.

- Preventing External Contaminant Ingress: Oil seal rings effectively block external contaminants such as dust, moisture, and dirt from entering the equipment. For instance, in wind turbine generator sets, they protect main shaft and gearbox bearings from harsh external environments.

- Maintaining Internal Lubrication and Cooling: By preventing oil escape, the seal ring ensures the lubricating oil maintains proper circulation, sustaining its lubrication and cooling effects and extending the equipment's service life.

- Improving Equipment Reliability and Safety: By strictly controlling leaks and contamination ingress, oil seal rings fundamentally improve the equipment's operational reliability and safety, significantly reducing the occurrence of catastrophic failures.

2. Application Locations of Oil Seal Rings

Oil seal rings are deployed across critical interfaces, often within complex sealing systems:

- Outside Bearing Housings: They are installed at the bearing housings at both ends of the generator to serve the dual purpose of preventing oil from entering the generator core and preventing external leaks.

- Main Shaft Seal Oil Baffle (Wind Turbines): A specialized floating seal ring with elasticity is often used here. Its design adapts to the rotating shaft's vibrations, guaranteeing long-term use without wear or an increased sealing gap, effectively preventing grease leaks.

- Triple-Flow Seal Oil System (Large Generators): This advanced system uses oil seal rings to introduce a third, vacuum-treated flow of pressurized oil. This completely isolates the air-side oil from the hydrogen-side oil, critically preventing both generator oil leaks and internal hydrogen leaks. The system also includes high-level automated monitoring for real-time parameter adjustment.

- Magnetic-Dynamic Seal Oil Baffle (Turbine Sets): This system utilizes oil seal rings in conjunction with a permanent magnet and spring plates. The design creates a "zero gravity" state for the inner ring during operation, which significantly reduces oil leakage by minimizing contact friction.

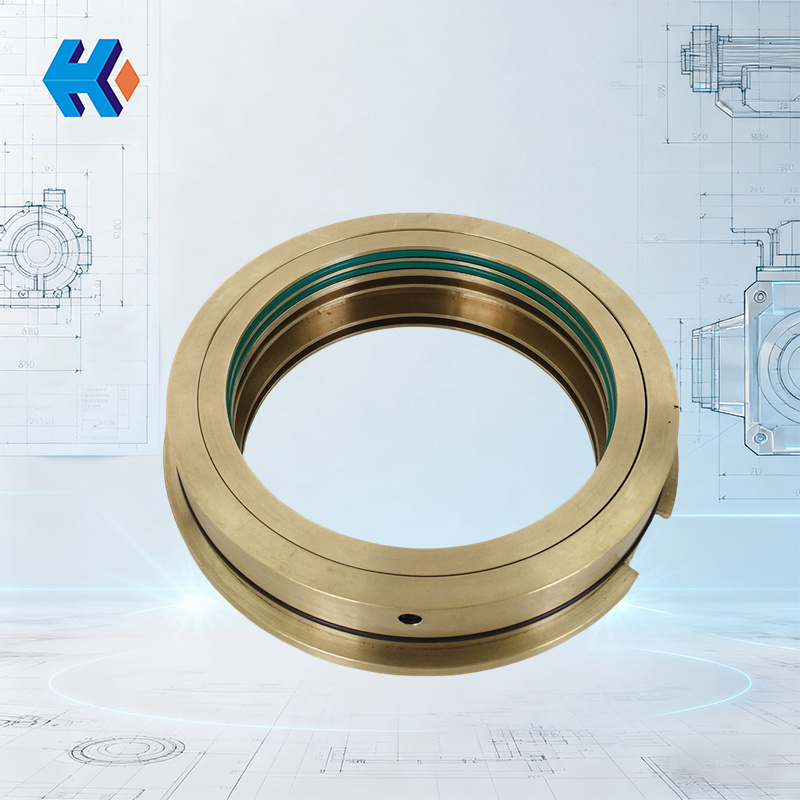

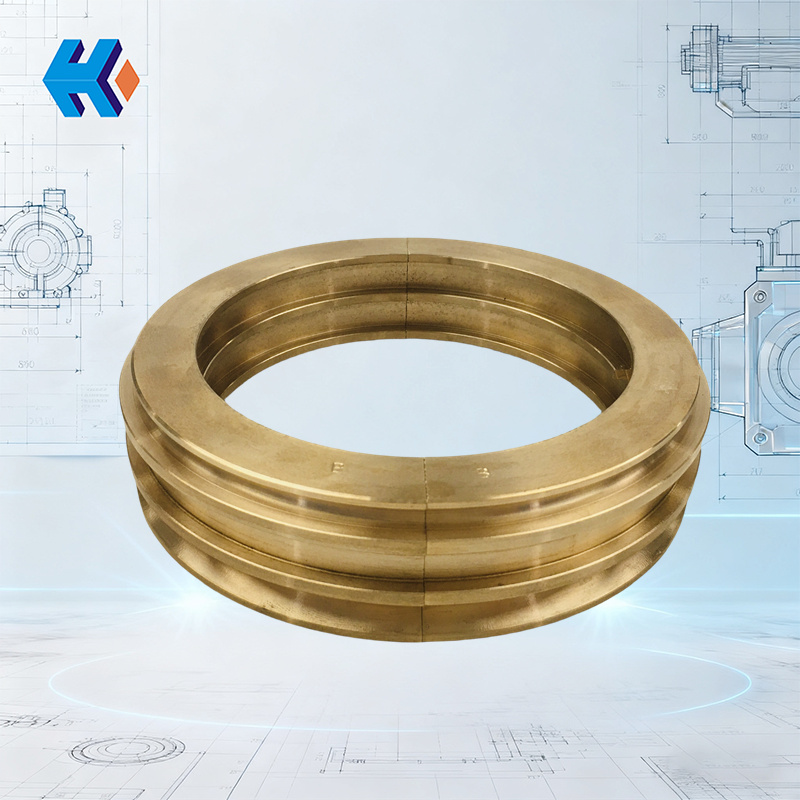

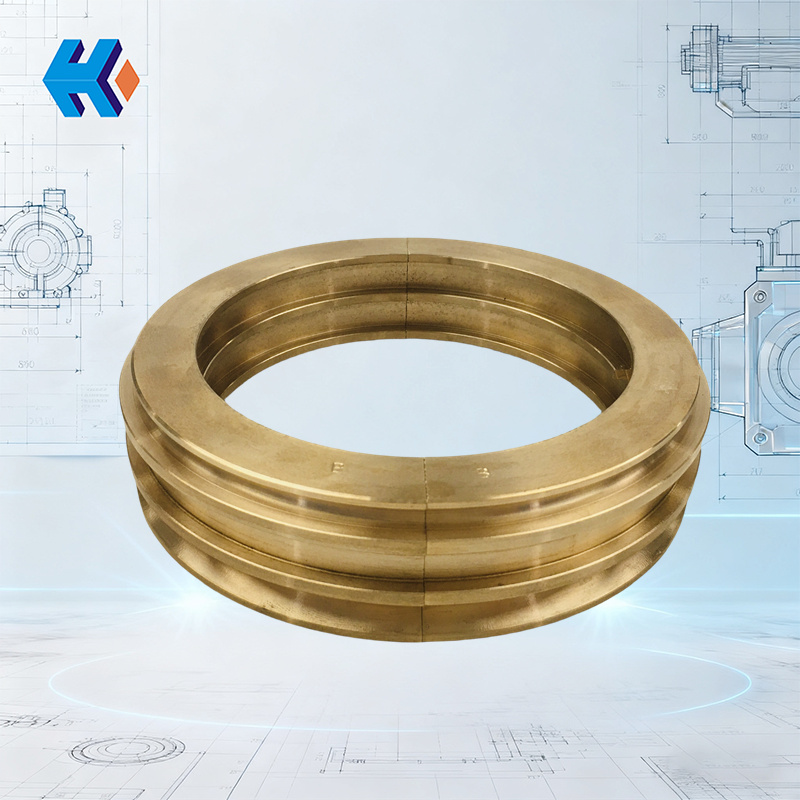

🔧 Precision Sealing: Custom Oil Seal Rings for Extreme Demands

We provide custom-engineered oil seal rings utilizing high-performance materials like specialized PTFE, FKM, or proprietary composites. Our products are precision-machined to exact fit and tolerance, designed for superior chemical and heat resistance, ensuring zero leakage and sustained performance in the most demanding hydrogen or air-cooled environments.

Oil leakage is a direct threat to operational efficiency, environmental compliance, and machine safety. Upgrade to reliable, custom-fitted sealing solutions.

Contact us for a technical consultation or a competitive quote on our high-reliability oil seal rings. Secure your generator's future today!

GET A FREE QUOTE AND CONSULTATION