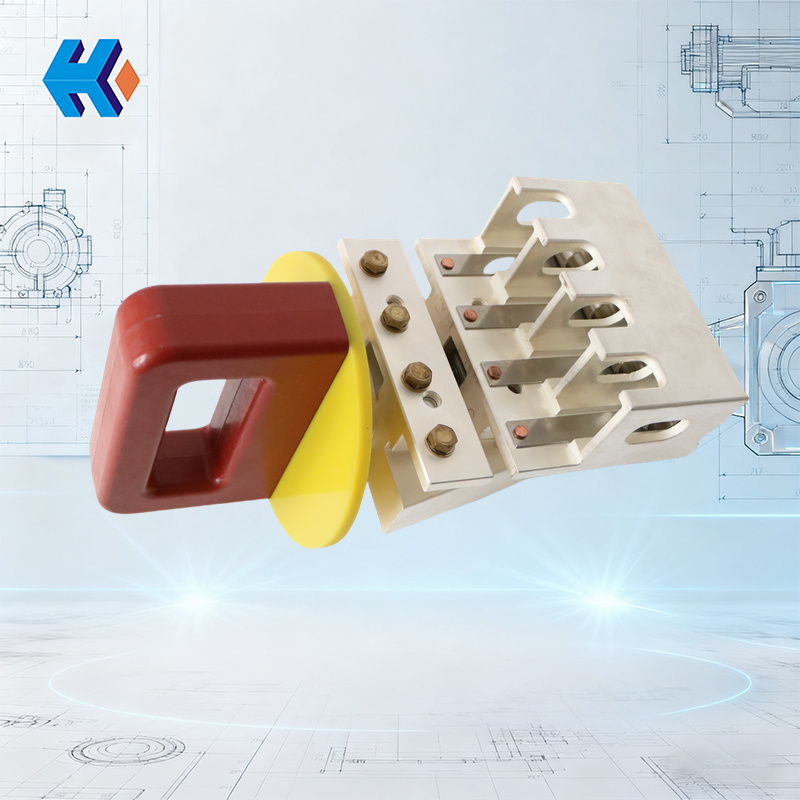

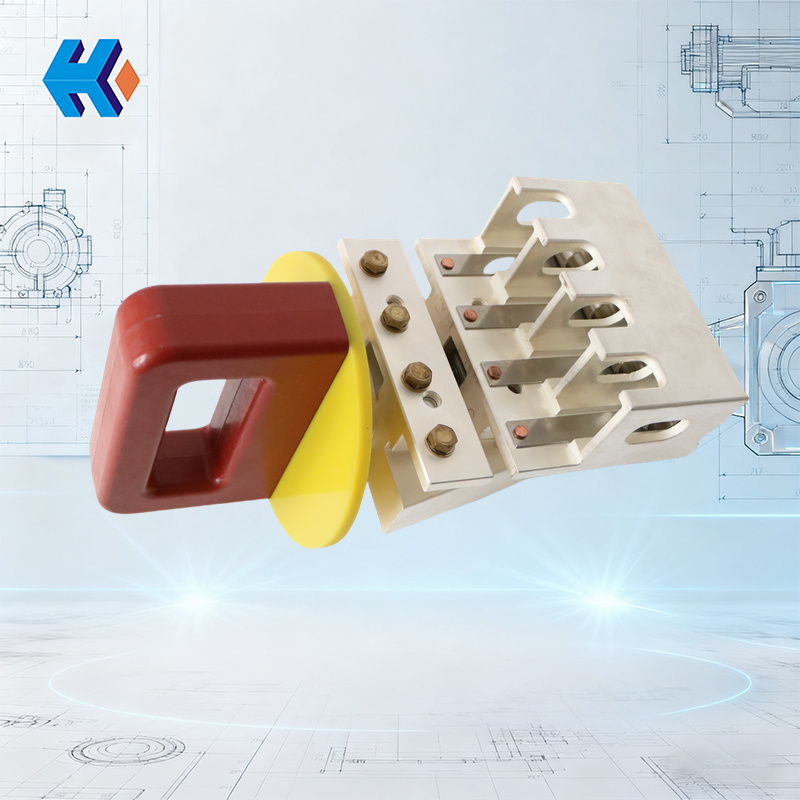

Generator Brush Holders and Accessaries in Power Plants

In a generator set, the carbon brush is a key component for transmitting electrical energy, and the brush holder is its essential support and fixation device. The function and accessories of the brush holder are crucial for the stable and reliable operation of the generator set.

1. Functions of a Brush Holder

- Fixing Carbon Brushes: The primary function is to fix the carbon brush, ensuring it remains stable during operation. The brush holder uses an internal spring mechanism to hold the carbon brush firmly against the slip ring, enabling continuous transfer of electrical energy while maintaining an appropriate force to prevent damage.

- Adjusting Carbon Brush Position: The brush holder features an adjustment mechanism (typically bolts and nuts) to change the carbon brush's position based on its wear or the condition of the slip ring surface. This ensures the brush and slip ring always maintain optimal contact.

- Protecting Carbon Brushes: The holder provides a stable operating environment, shielding the carbon brush from external factors like dust and impurities. Its structure prevents the brush from jumping or shifting during rotation, thereby extending its service life.

- Facilitating Maintenance and Replacement: The brush holder is designed for easy installation and replacement of carbon brushes. Equipped with quick-release mechanisms (e.g., clips or threaded connections), operators can quickly remove the holder and replace worn brushes, minimizing generator downtime.

2. Brush Holder Accessories

Critical accessories ensure the brush holder performs its functions reliably:

- Spring: The spring provides the crucial force to the carbon brush, ensuring good, consistent contact with the slip ring. The force must be moderate—too strong can damage the slip ring, too weak leads to poor contact and energy transfer issues.

- Brush Pigtail: This is a conductive component, typically made of braided copper wires, that connects the carbon brush to the external excitation circuit. It transfers DC current to the brush and then to the slip ring.

- Brush Holder Bracket: The fixture used to secure the brush holder to a stationary part of the generator. It is usually metal, providing the necessary strength and stability to maintain precise positioning during operation.

- Adjustment Bolts and Nuts: These form the adjustment mechanism, allowing operators to fine-tune the brush's position and the contact pressure with the slip ring to maintain optimal contact quality.

3. Maintenance and Inspection of Brush Holders

- Regular Inspection: Periodically check the mounting security and the internal spring. Replace the spring if it loses elasticity or shows damage.

- Cleaning and Maintenance: Regularly clean dust and impurities from the brush holder interior. Check the brush pigtail for conductivity; replace immediately if broken or damaged.

- Carbon Brush Wear Check: Monitor wear, replacing the brush promptly when it has worn down by two-thirds. Inspect contact for abnormal signs like jumping, overheating, or sparking.

- Temperature Monitoring: Use a thermometer to periodically check the brush and slip ring temperature, ensuring it remains below 120°C. High temperatures require immediate action.

4. Installation and Debugging of Brush Holders

Installation Steps:

- Fix the brush holder bracket securely onto a stationary part of the generator.

- Mount the brush holder on the bracket, aligning its center with the slip ring's centerline.

- Insert the carbon brush and adjust the spring force to ensure optimal contact with the slip ring.

Debugging Methods:

- Start the generator and observe the brush's operation, checking for abnormal phenomena (jumping, sparking, overheating).

- Use a clamp ammeter to measure the carbon brush current, ensuring even distribution and no overcurrent.

- Regularly check brush wear and adjust its position as needed to maintain peak performance.

🛠️ Custom Brush Holder Solutions: Engineered for Your Generator

We provide precision custom manufacturing of brush holders and brackets, utilizing specialized materials engineered to meet the exact specifications of your excitation system. Maximize current transfer efficiency and minimize maintenance cycles with a perfectly optimized brush holder system.

Don't let faulty brush holders risk your generator's output. A poorly maintained contact system leads directly to energy loss and failure.

Contact us to connect with our engineering team for a technical consultation or a competitive quote on our high-reliability brush holders. Ensure flawless electrical transfer now!