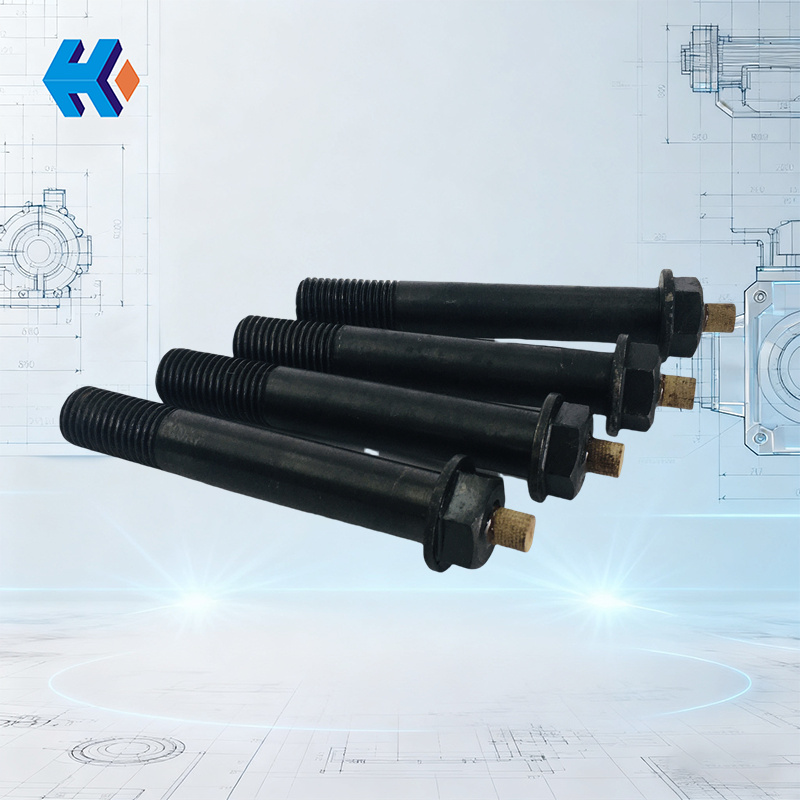

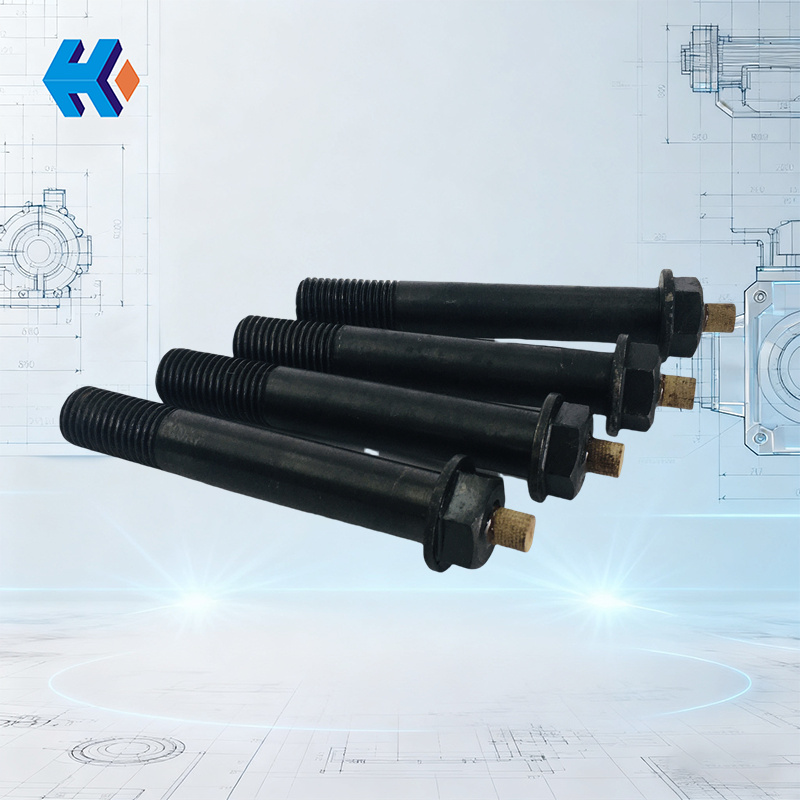

Insulation Bolts for Generator Units QFSN-300-2-20B

1. Core Definition of Insulating Bolts

Insulating bolts are special fasteners designed specifically for large generator sets such as QFSN-300-2-20B, QFSN-600-2YHG. Through a composite design of "insulating base material + structural reinforcement", they not only fulfill the mechanical fastening function but also block current conduction paths. This solves issues such as leakage and short circuits that are prone to occur with traditional metal bolts, making them widely applicable in scenarios requiring insulation protection, such as power generation, power transformation, and electrical equipment.

2. In-depth Analysis of Core Functions

- Precise Blocking of Current Leakage

They not only prevent current from conducting to adjacent conductive structures through metal components but also suppress the generation of micro-leakage current. Typically, their insulation resistance value is ≥10¹⁰Ω, far exceeding the industry's basic standard (≥10⁸Ω). This avoids equipment failures, electromagnetic interference, and even electric shock risks for maintenance personnel caused by current leakage, making them particularly suitable for insulation protection needs of high-voltage equipment.

- Stable Mechanical Fixation

They overcome the pain point that "insulation and strength cannot be achieved simultaneously". While ensuring insulation performance, they also possess excellent mechanical load-bearing capacity: tensile strength up to 80-120MPa and shear strength ≥50MPa. They can withstand vibration, impact, and thermal expansion/contraction stresses during equipment operation, ensuring long-term stability of components and preventing equipment displacement or damage caused by fastening failure.

- All-scenario Weather Resistance and Corrosion Resistance

The base material is mostly made of corrosion-resistant and insulating materials such as glass fiber-reinforced epoxy resin (FRP) and polyimide. Some key stress-bearing parts are embedded with metal inserts treated with surface galvanization/passivation. They can withstand acid-alkali corrosion, humidity changes (relative humidity below 95%), and high-temperature aging in industrial environments, maintaining stable performance within a wide temperature range of -40℃ to 150℃, and are suitable for harsh working conditions such as outdoor, humid, and dusty environments.

3. Supplementary Performance Advantages

- Temperature Adaptability: Meets the needs of high-temperature operating equipment such as generators and transformers. It can withstand instantaneous high temperatures of 200℃ in the short term and has no problem of insulation layer aging or cracking during long-term operation.

- Installation Flexibility: Supports customization of various structures such as hexagon head, cylindrical head, and countersunk head to adapt to different installation spaces. The surface is smooth without burrs, avoiding damage to the insulation layer during installation.

- Detection Convenience: Some products integrate insulation performance indicators, and the insulation resistance can be quickly detected with a multimeter, simplifying the performance inspection process during maintenance.

4. Typical Application Scenarios and Values

- Connection between Bearing Shell and Bearing Seat

Shaft current is prone to generate during the operation of generators and motors. If it is conducted to the machine base for grounding through the bearing, it will cause electrical pitting on bearing raceways and grease deterioration, shortening the bearing life by 30%-50%. Insulating bolts block the shaft current path while ensuring the sealing and fixation of the bearing seat, extending the equipment maintenance cycle.

- Fixation of Generator Stator Windings

Electromagnetic force and heat are generated during the operation of stator windings. Traditional bolts tend to form a "winding-machine base" conductive circuit, causing insulation breakdown. Insulating bolts maintain the insulation distance of the windings while resisting loosening caused by vibration, ensuring stable power generation efficiency and reducing the risk of short-circuit faults.

- Key Connections in the Excitation System

The excitation system is the core of generator magnetic field regulation. If the excitation winding and stator winding are connected through bolts, it will cause magnetic field disturbance and voltage fluctuation. Insulating bolts accurately isolate the conductive paths of the two windings, ensuring the excitation system's precise control of the magnetic field and avoiding power grid fluctuations caused by voltage abnormalities.

- Connection between Generator End Cover and Frame

The end cover is not only a sealing component of the unit but also needs to isolate the frame's metal parts from external conductive structures. While realizing the sealing and fixation of the end cover, insulating bolts prevent current from conducting to the frame through the end cover, avoiding the risk of electric shock to maintenance personnel due to the frame being charged, and at the same time blocking dust and moisture from entering the unit.

- Connections in the Generator Cooling System

If the circulating water, oil, and other media in the cooling system come into contact with conductive components, they are likely to form short-circuit channels. Insulating bolts isolate the electrical connection between the cooling circuit and the unit body, not only ensuring efficient heat dissipation of the cooling medium but also avoiding insulation failure caused by medium conductivity, thus ensuring the long-term stable operation of the unit.

5. Selection and Cooperation Suggestions

If you are facing the following problems:

- Frequent leakage and short-circuit faults of power equipment due to insufficient bolt insulation;

- Traditional bolts are easily damaged under corrosive and high-temperature working conditions, increasing maintenance costs;

- Need to customize special-specification insulating bolts to adapt to non-standard equipment;

Contact us now to obtain your exclusive insulating bolt technical solution and quotation, and let special fasteners become a "protective shield" for the safe operation of the power plant!