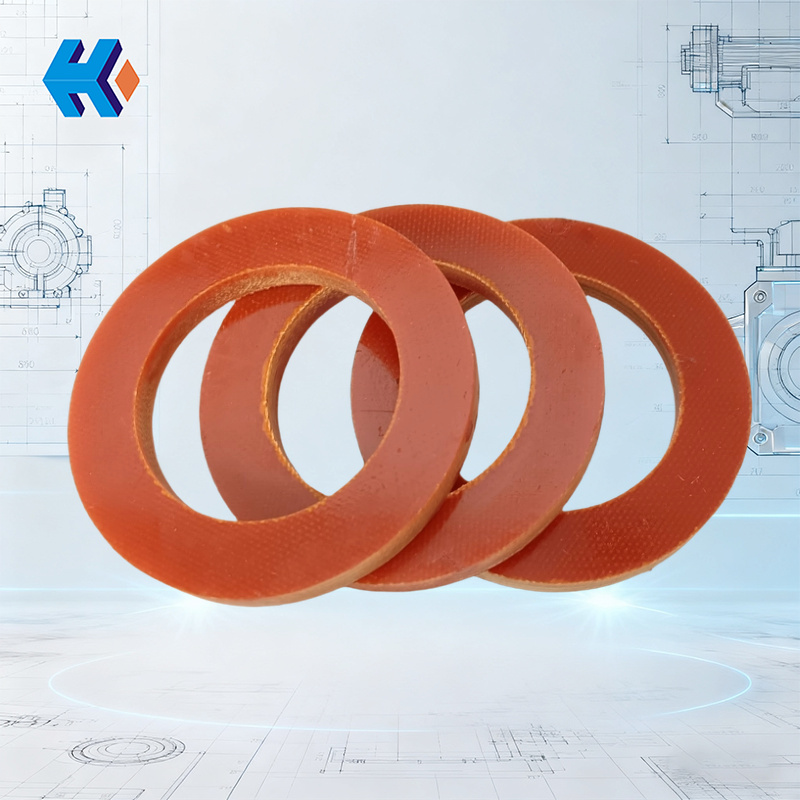

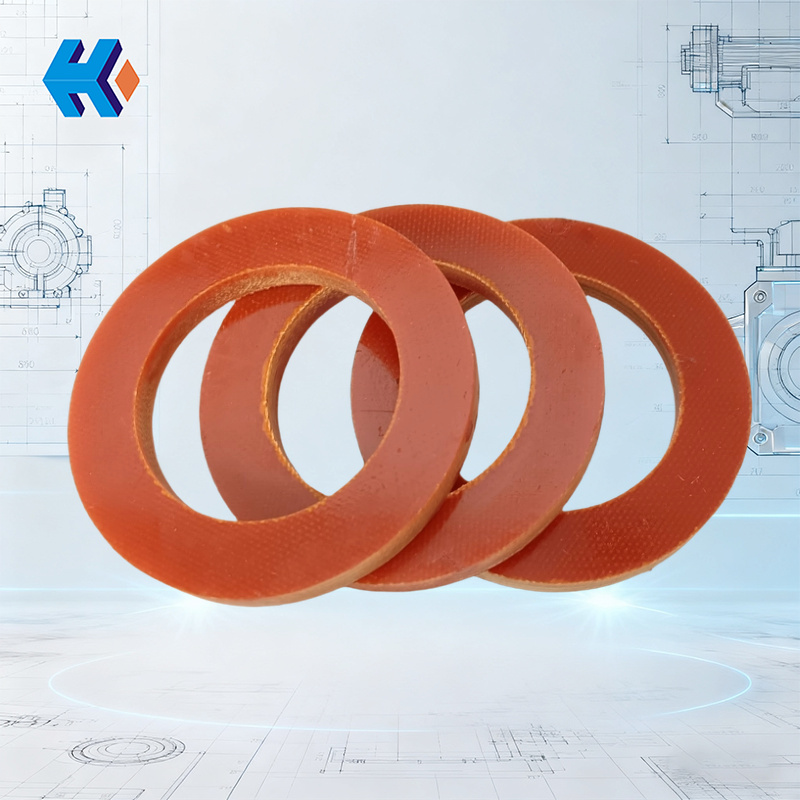

Fiberglass Insulating Washers for Generators

Insulating washers are important components in generator units QFS-125-2 to isolate current and prevent short circuits and electric shocks. They are typically made from materials with excellent insulating and mechanical properties.

Functions

- Isolating current: They effectively isolate current to prevent direct flow or short circuits.

- Preventing leakage: They can prevent electrical equipment from leaking electricity.

- Providing sealing effect: In some applications, they can provide a sealing effect to prevent liquid or gas leakage.

- Mechanical protection: They provide mechanical protection against damage from vibration or impact during operation.

- Heat and fire resistance: Some materials have good heat and fire resistance to protect equipment in high-temperature or fire environments.

Application Locations

- Turbine-end bearing insulating washers: Installed at the bottom and sides of the generator's turbine-end bearing to prevent shaft currents.

- Exciter-end bearing sleeve insulating washers: Installed at the bottom and sides of the exciter-end bearing sleeve to ensure electrical insulation.

- Bearing seat base insulating washers: Installed at the base of the generator's bearing seat to isolate it from the foundation.

- Excitation transformer insulating blocks: Installed on the fixing clamps and connecting bolts of the excitation transformer's core and coils.

- Rotor magnetic pole insulating washers: Installed at the bottom and sides of the rotor magnetic poles to isolate them from the rotor shaft.