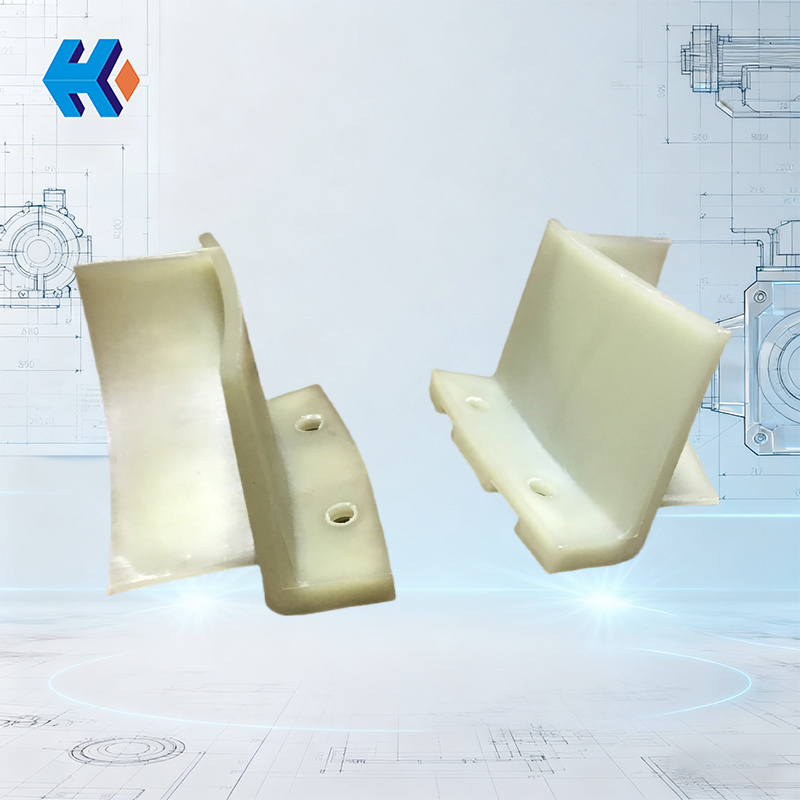

Generator Rotor Air Guide Vanes

In large generator sets such as QFS-300-2 and QFSN-600-2YHG, air guide vanes (also known as guide blades or stationary blades) at the turbine end and exciter end have different designs and functions to optimize airflow, improve efficiency, and protect equipment.

Turbine-End Air Guide Vane Design Features

- Optimize airflow direction: They guide airflow to enter the rotor blades at the optimal angle, improving aerodynamic efficiency.

- Reduce secondary flow losses: Their design focuses on reducing secondary flow losses by optimizing blade camber and height.

- Improve aerodynamic performance: They effectively improve aerodynamic performance by optimizing the blade's aerodynamic parameters.

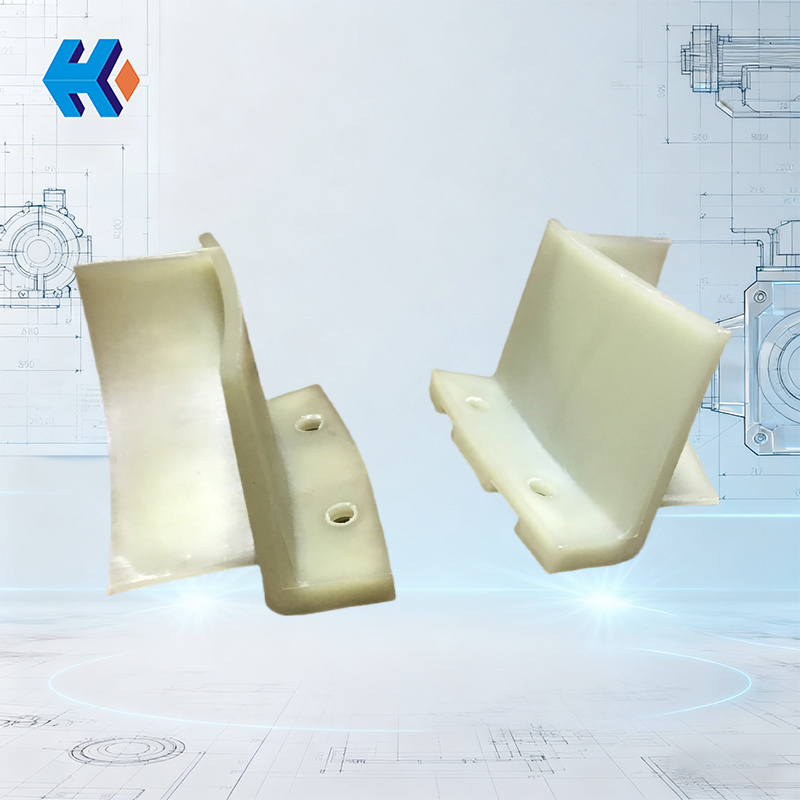

- Exciter-End Air Guide Vane Design Features

- Match moving blade aerodynamic design: Their design must match the aerodynamic design of the moving blades (rotor blades).

- Enhance airflow stability: They are designed to enhance the stability of the airflow by reducing turbulence and vortices.

- Improve overall efficiency: They improve the overall efficiency of the generator set by optimizing the airflow path.

Functions of Guide Vanes

- Optimize airflow: Their main function is to ensure airflow passes uniformly through the rotor blades, improving generator efficiency.

- Reduce dust accumulation: They can reduce dust accumulation on the blade surface.

- Improve stability: They help reduce the impact of airflow on the blades, improving operational stability.

- Lightning protection: In some designs, they also have lightning protection functions.