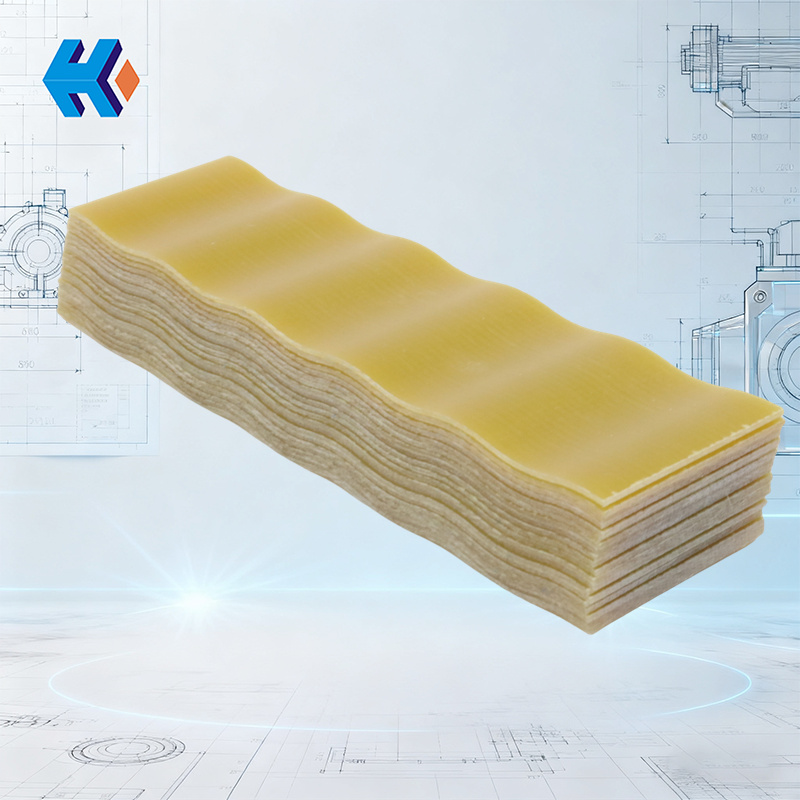

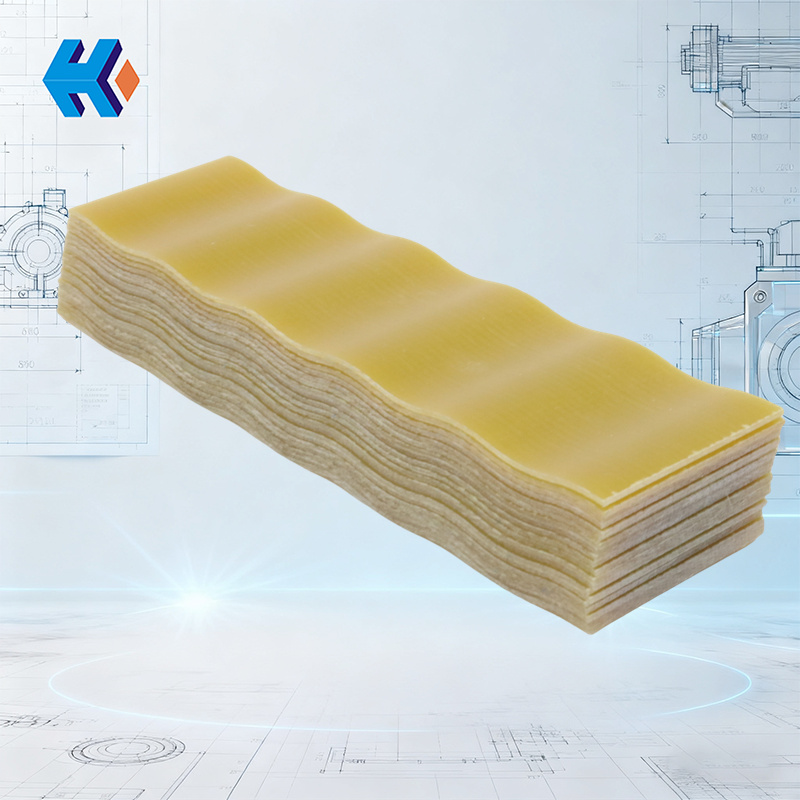

Elastic Fiberglass Corrugated Sheets

In generator sets such as QFSN-350-2-20, elastic fiberglass corrugated sheets are widely used inside stator slots to secure the stator winding bars and ensure stable generator operation.

Application Locations

- Inside the stator slots:

- Side position: Elastic corrugated plates are typically installed on the sides of the stator slots, between the winding bars and the slot walls. Their function is to provide continuous pressing force to securely fix the winding bars within the slots.

- Top position: At the top of the stator slots, they are used to secure the stator winding bars, preventing them from loosening during operation. This design improves winding bar stability and reduces wear caused by vibration.

- Under-wedge position: They are also installed under the slot wedges to further enhance the winding bar fixation.

Functions

- Provide continuous pressing force: The plates generate a spring-back force when compressed, providing a continuous pressing force to prevent the winding bars from loosening due to vibration.

- Compensate for thermal expansion: They can compensate for radial slot size changes caused by thermal effects, ensuring stable operation during temperature variations.

- Damping effect: They provide an excellent damping effect in the radial slot direction, reducing coil vibration caused by electromagnetic forces.

- Insulation protection: Made from insulating materials, they provide electrical insulation to prevent short circuits between the stator coils and the stator core.

- Optimize the installation process: Their design allows them to be easily pushed into the slots via a simple spring path, optimizing the installation process of the winding rods.