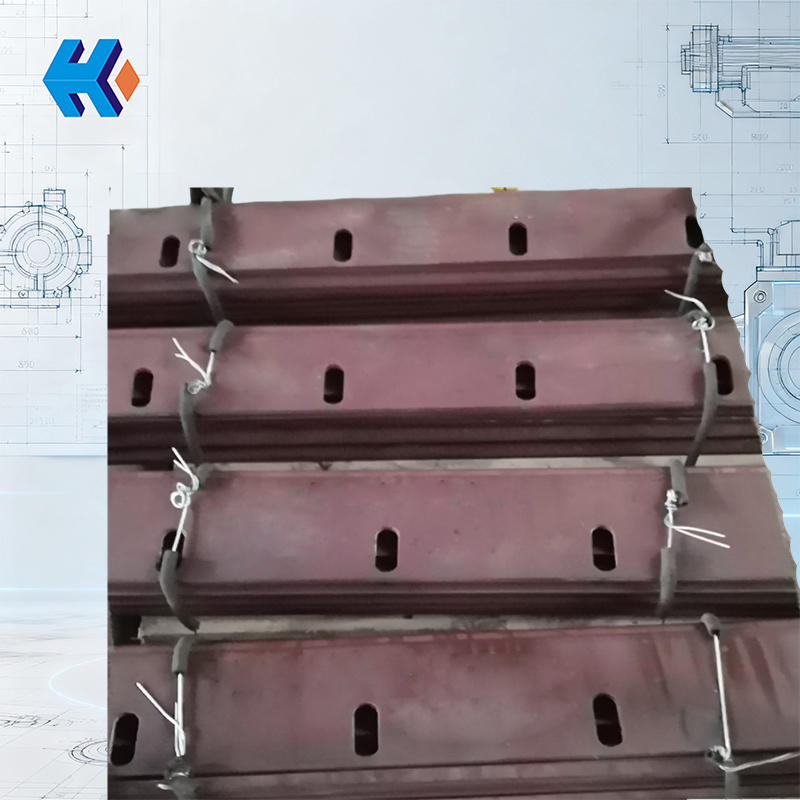

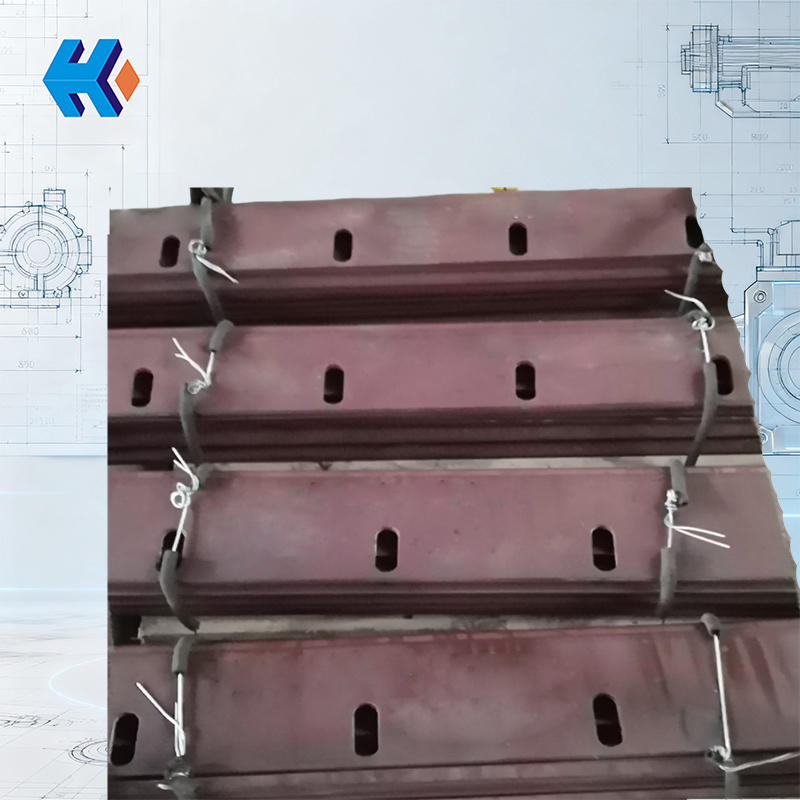

Cold-end Radial Sealing Plate for Air Preheater

The cold-end radial sealing plate is a core sealing component in the cold-end area of a rotary air preheater (APH) used to reduce air leakage. The APH transfers heat between flue gas and air through rotor rotation. However, there is a radial gap between the rotor and the fixed outer casing (or sector plates). At the cold end, because the flue gas temperature is low, condensation and corrosion can easily occur. Furthermore, the rotor undergoes “mushroom-like” thermal deformation due to temperature changes (cold-end shrinkage, hot-end expansion) , which increases the radial gap, making it easier for high-pressure air to leak to the low-pressure flue gas side (“air leakage”). The core function of the cold-end radial sealing plate is to seal the radial gap at the cold end, reduce air leakage to the flue gas side, thereby lowering the air leakage rate, improve heat recovery efficiency, and reduce energy consumption of induced draft fans and forced draft fans.

Structure and Installation of Radial Sealing Plate

- Arrangement direction: Installed radially along the APH rotor (from the rotor center to the edge), perpendicular to the rotor’s rotation path, directly covering the radial gap area.

- Installation location: Typically fixed to the cold end of the rotor (rotor edge) or the corresponding sector plate (fixed part), creating a dynamic seal as the rotor rotates or works in conjunction with the sector plate.

- Material selection: Because the cold-end flue gas temperature is low and condensation is prone to occur (which can cause sulfuric acid corrosion, especially when burning high-sulfur coal), the material must have low-temperature corrosion resistance and wear resistance. Common materials include:

- Corten steel (weathering steel, with excellent atmospheric corrosion resistance).

- Stainless steel (such as 316L, with stronger corrosion resistance, suitable for high-sulfur fuel scenarios).

- Some high-end designs add a wear-resistant coating (such as tungsten carbide) to the surface to extend the service life.

- Shape features: Mostly thin plate structures with a certain degree of elasticity (thickness is usually a few millimeters) that can adapt to gap changes through their own deformation.