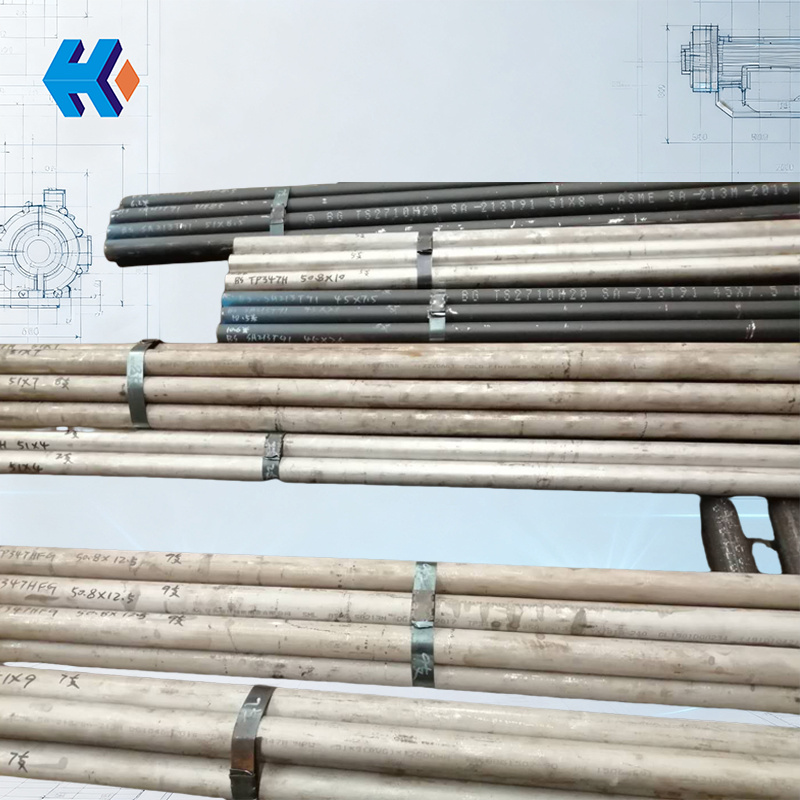

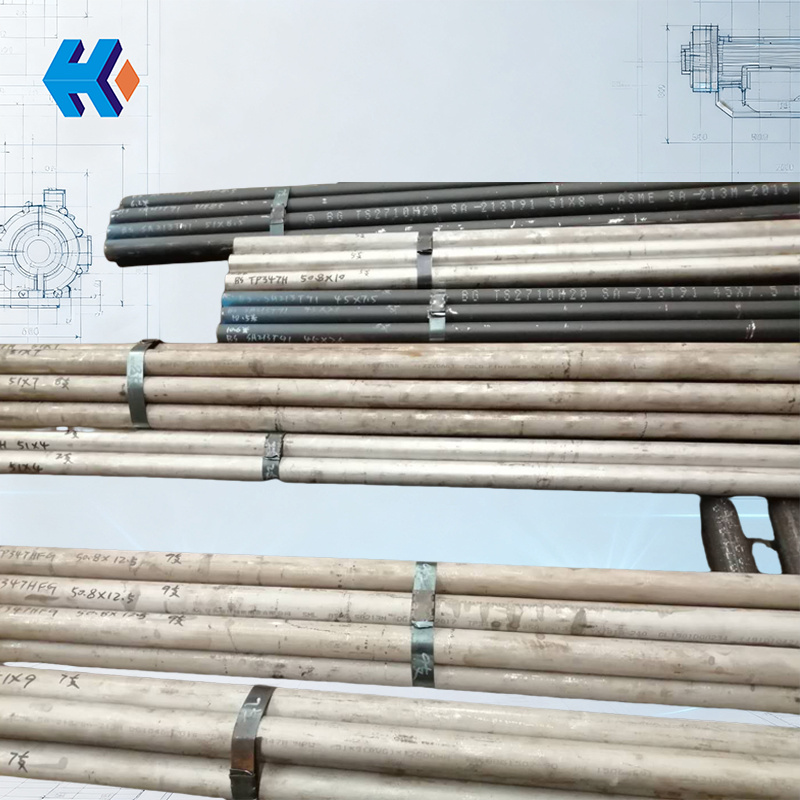

High-Pressure Seamless Steel Pipe

High-pressure seamless steel pipes are key pressure-bearing pipelines designed for high-pressure environments, widely used in core components of boilers such as superheaters, reheaters, economizers, and main steam pipes. Because they directly withstand high temperatures (typically above 300°C, and up to 600°C or more) and high pressure (generally exceeding 10MPa, and up to 30MPa or more in some supercritical units) , they have extremely high requirements for material performance, manufacturing processes, and quality control.

Seamless Pipes Characteristics and Technical Requirements

-

High strength and heat resistance: Must maintain sufficient tensile strength, yield strength, and creep strength under high temperature and high pressure to prevent plastic deformation or fracture from excessive stress during long-term operation.

- Good oxidation and corrosion resistance: Must resist oxidative corrosion (such as the formation of scale on the steam side) and media corrosion (such as erosion by sulfur and chlorine elements in the flue gas) to prevent pipe wall thinning or leakage.

- Uniform structure and density: Seamless steel pipes have no weld defects, avoiding potential issues like pores and cracks that can exist in welded joints. The material composition and metallographic structure must also be uniform to ensure consistent overall mechanical properties.

- Dimensional accuracy and surface quality: The outer diameter and wall thickness deviation must be strictly controlled (e.g., wall thickness tolerance ≤ ±10%). The inner wall should be smooth to reduce fluid flow resistance, and the outer wall should be flat to facilitate installation and insulation.

Manufacturing Standards and Process

The manufacturing of high-pressure seamless steel pipes for boilers must follow strict standards and processes to ensure quality and performance.

- GB/T 5310-2023 “Seamless steel tubes for high pressure boilers”: This standard specifies the dimensions, shape, technical requirements, and test methods for steel pipes. It requires steel pipes to undergo strict heat treatment and surface treatment processes, such as normalizing, tempering, and quenching, to improve their microstructure and physical properties.

- GB/T 17396 “Seamless steel tubes dimensions, shapes, weights and tolerances”.

- Other international standards: ASME SA-213 (Standard Specification for Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger Tubes), DIN 17175 (German standard for high-pressure boiler tubes).