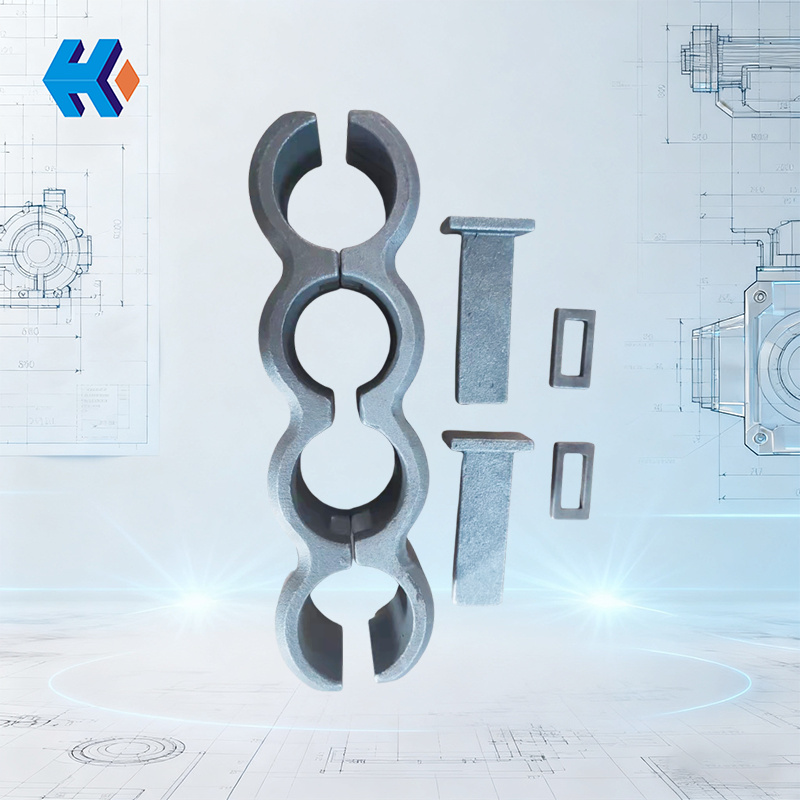

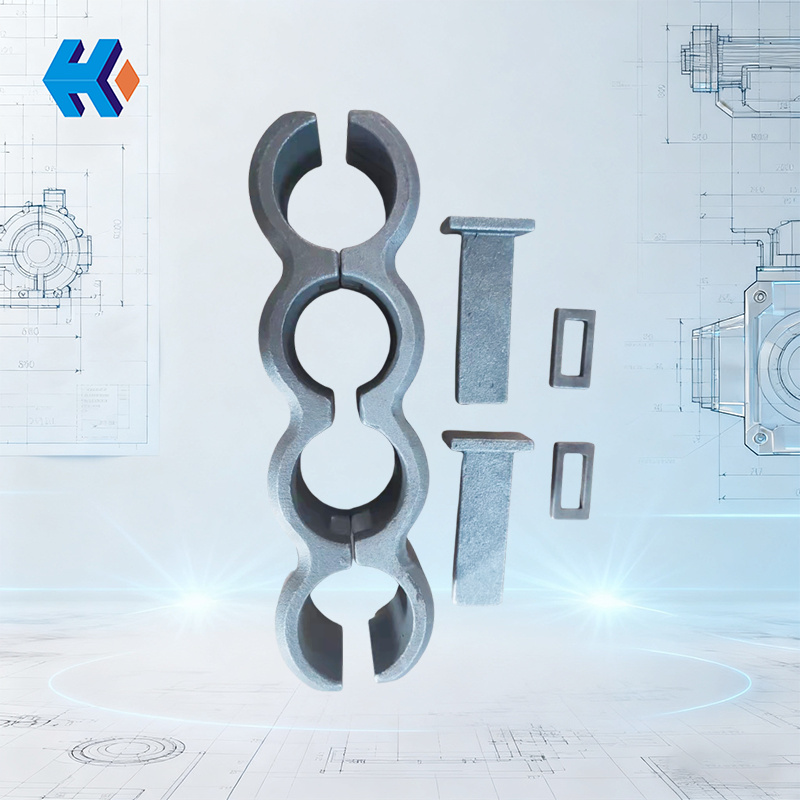

Pipe Clamp for Boiler Waterwall Panel

A pipe clamp is a mechanical accessory used for fixing, supporting, or guiding pipes. It is widely used in piping systems for oil, chemical, power, construction, and water supply and drainage. Its core function is to ensure that pipes remain stable during operation and to prevent displacement, deformation, or damage caused by vibration, thermal expansion and contraction, or external impacts.

Functions and Classifications of Pipe Clamps

-

Fixed pipe clamp:

-

Function: Rigidly fixes pipes to brackets, walls, or equipment, restricting axial and radial displacement. It is suitable for scenarios where pipes are not allowed to move significantly (e.g., high-pressure pipes, low-vibration systems).

- Features: The connection to the pipe and the fixed base (such as a steel structure bracket) is rigid, providing strong clamping force. It usually has a bolted fastening structure to ensure the pipe’s stability.

-

-

Sliding pipe clamp:

-

Function: Allows the pipe to slide freely along the axial direction to compensate for thermal expansion or contraction caused by temperature changes, preventing the pipe from bending or cracking due to thermal stress.

- Features: The contact surface between the clamp and the pipe or between the clamp and the fixed bracket has a sliding surface (such as a PTFE sliding plate or stainless steel slider) to reduce friction and ensure smooth pipe expansion and contraction.

-

-

Guide pipe clamp:

-

Function: Restricts the pipe’s radial displacement but allows free axial movement. It is mainly used to guide the pipe to move in a predetermined direction (usually axial) during thermal expansion and contraction, preventing it from shifting or wobbling.

- Features: The structure includes lateral limit devices (such as baffles or guide grooves) that restrain the pipe’s lateral swing but do not obstruct axial expansion and contraction. It is suitable for long straight pipe sections or for fixing pipes near bends.

-

-

Vibration-damping pipe clamp:

-

Function: Absorbs pipe vibrations through elastic components (such as rubber pads or springs) to reduce noise and damage to pipes and equipment from vibrations (e.g., vibrations from pipes at the outlet of pumps and compressors).

- Features: An elastic material is installed between the clamp body and the pipe, providing a certain buffering and damping effect. It is suitable for piping systems with frequent vibrations (e.g., chemical pump sets, turbine exhaust pipes).

-