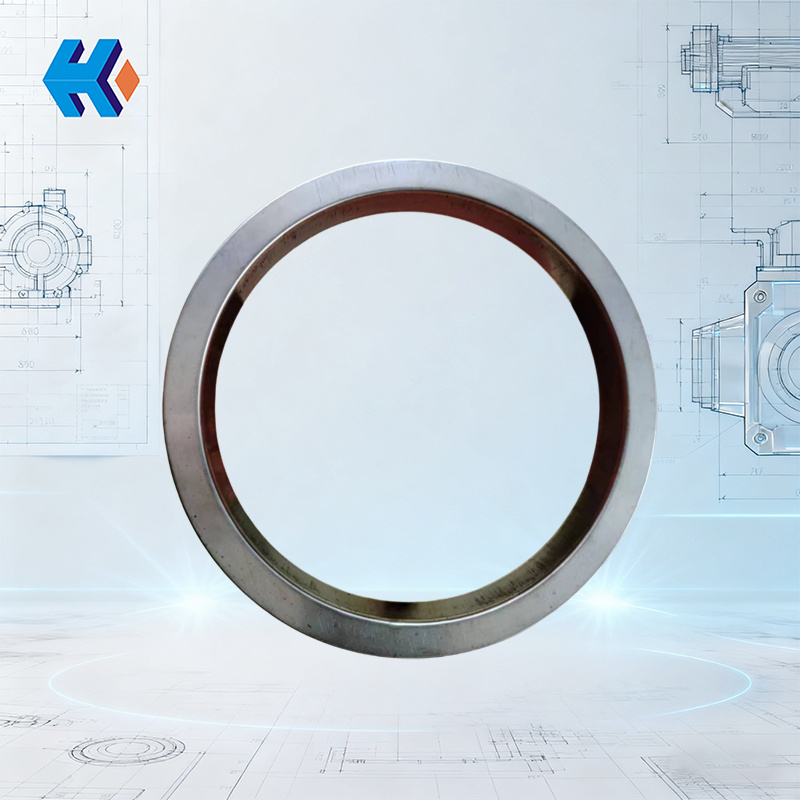

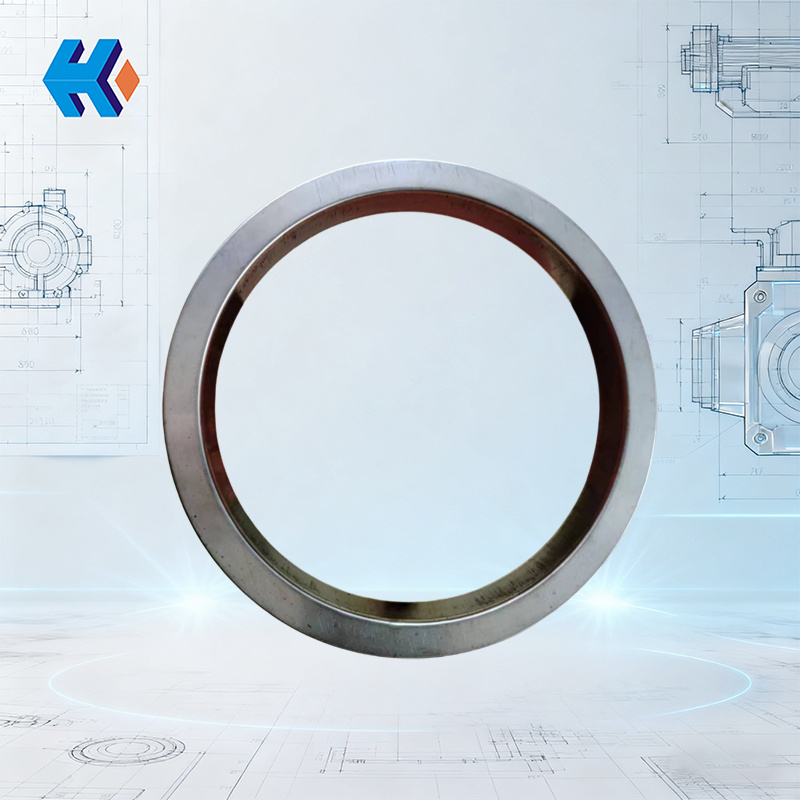

High-Pressure Heater Manhole Self-sealing Ring

The high-pressure heater manhole self-sealing ring prevents internal media leakage from high-pressure heaters, ensuring safe operation. As the internal pressure changes, the self-sealing ring can automatically adjust its sealing effect to ensure reliability. High-pressure heaters are key equipment in power plants and large industrial boilers that use steam extracted from steam turbines to heat feedwater. The internal working pressure is usually above 10MPa, and the temperature can reach 300-400°C.

Materials of the Self-sealing Ring

-

Flexible graphite: A common sealing material with good high-temperature resistance and chemical stability. It maintains a stable sealing effect in high-temperature and high-pressure environments.

- Full or partial metal cladding: In some designs, the upper end of the flexible graphite ring body is equipped with a full or partial metal cladding to enhance its mechanical strength and wear resistance.

Installation and Maintenance Guidelines

-

Pre-installation inspection: Clean the sealing surface, ensuring it is free of scratches, cracks, or rust. Check the ring’s elasticity; the rebound rate should be ≥20%, and the tear strength should be within the standard range.

- Re-installation steps: Press the sealing ring evenly into the manhole door groove, avoiding local warping. Install the four-segment anti-detachment device to prevent the sealing ring from shifting under high pressure.

- Operation monitoring: Regularly check the leakage rate. If the high-pressure heater water level fluctuates abnormally, the unit should be shut down for maintenance immediately. It is recommended to replace the sealing ring every 6 months, and this period should be shortened to 3 months for ultra-high-pressure conditions.