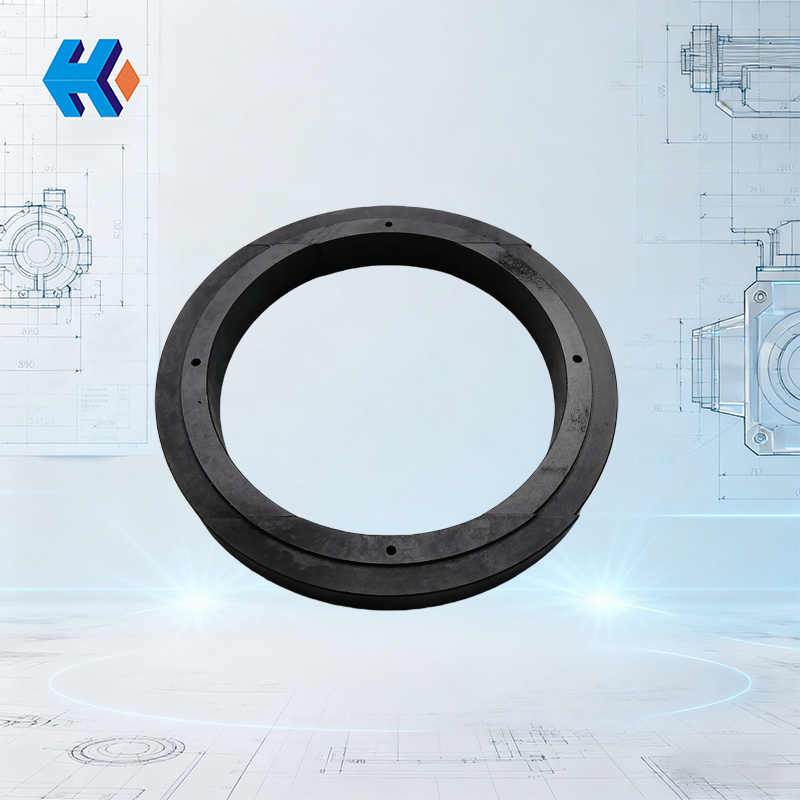

Four-Segment Ring for High-Temperature Reheater Block Valve

The high-temperature reheater block valve four-segment ring is an important sealing component used in high-temperature reheater block valves. In these valves, the four-segment ring plays a key sealing role, creating a reliable seal between the valve bonnet and the valve body. It prevents the leakage of high-temperature and high-pressure media, ensuring the normal operation of the system.

Installation and Maintenance

-

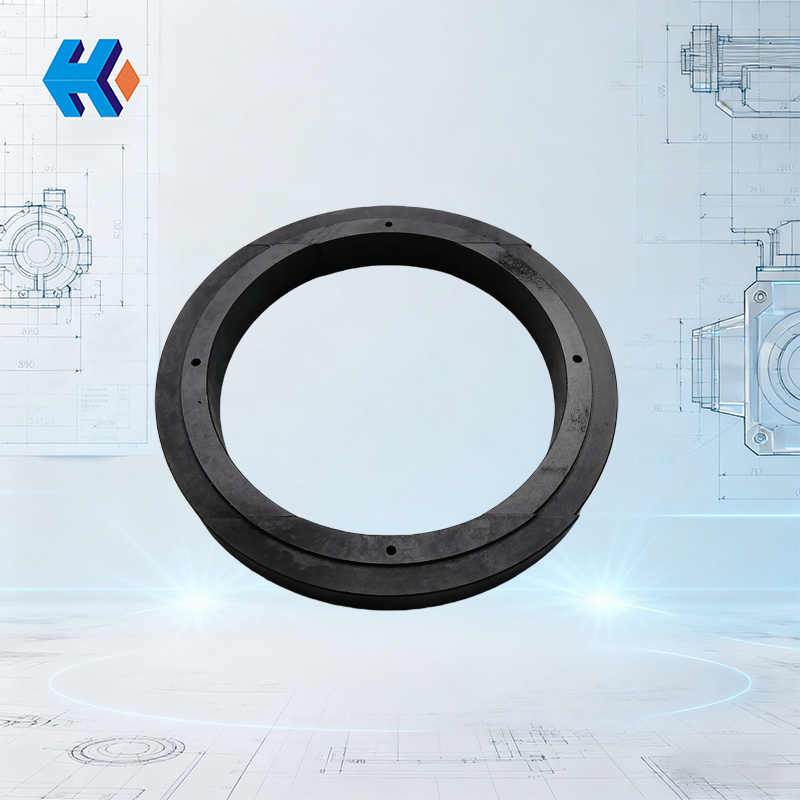

Installation essentials: When installing the four-segment ring, first ensure that the valve body’s installation groove and the stop limit surface on the support plate are clean and smooth, free of oil stains, rust, burrs, or other impurities. Then, place each ring segment into the installation groove in sequence, ensuring their outer ends fit against the inner wall of the groove and the inner ends align with the stop limit. The four-segment ring is then secured to the support plate with bolts or other connectors. During this process, attention should be paid to the tightening torque of the bolts to ensure the ring is securely and evenly installed.

-

Maintenance precautions: During the operation of the high-temperature reheater, regularly check the sealing performance of the four-segment ring for any signs of leakage. Also, inspect the surface of the ring for wear, corrosion, or deformation. If any issues are found, repair or replace it promptly. Additionally, during each overhaul, clean and maintain the four-segment ring, remove surface dirt and impurities, and apply an appropriate amount of high-temperature anti-seize agent or lubricant to facilitate future disassembly and installation.