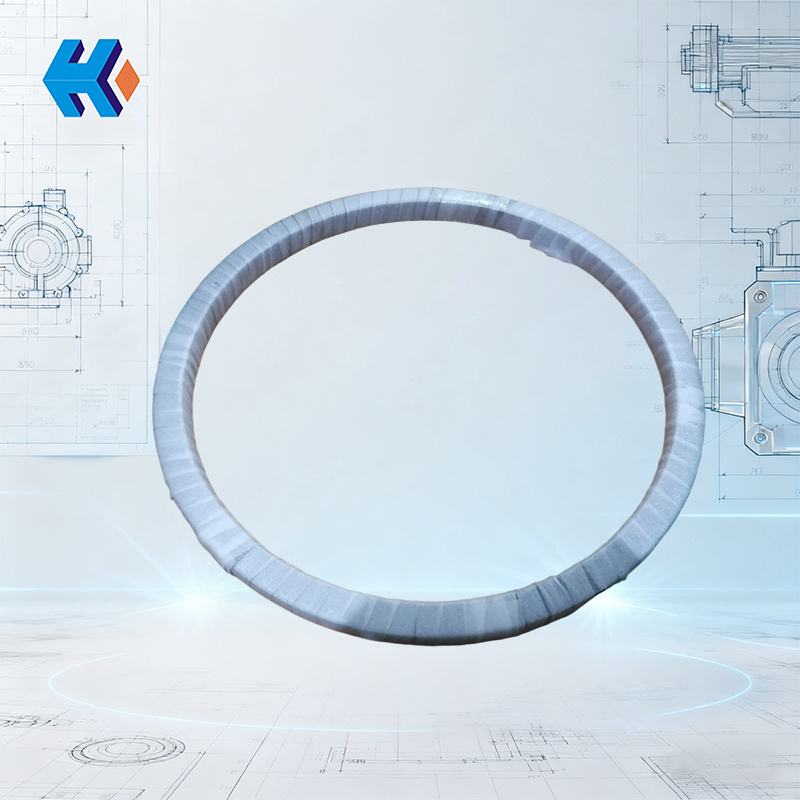

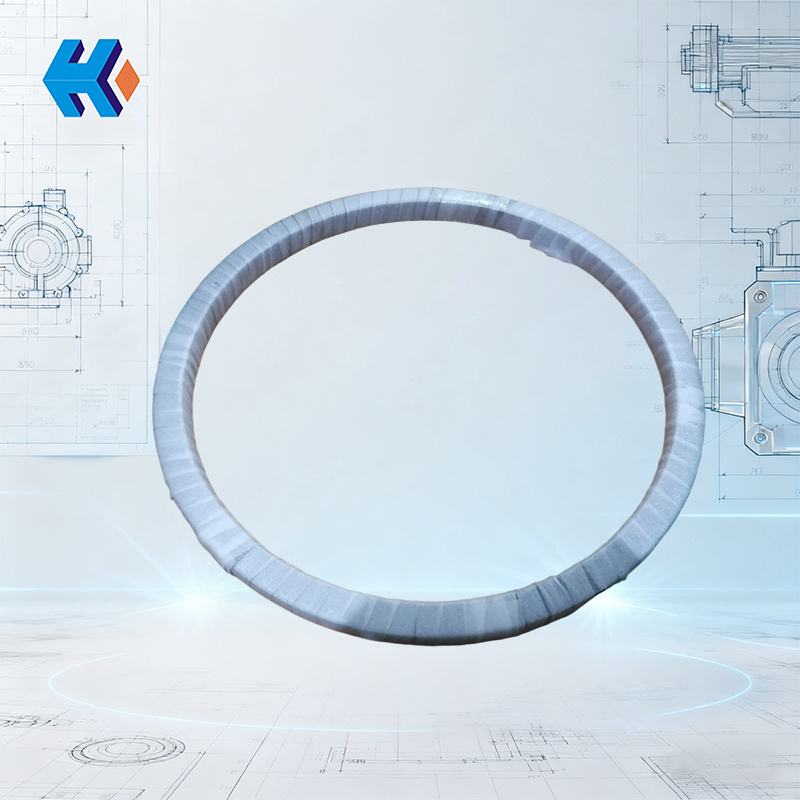

High-Temperature Superheater Block Valve Bush Ring

The high-temperature superheater block valve bush ring is a key auxiliary component in the boiler’s high-temperature pressure system. The block valve is a valve used for temporary or long-term sealing of pipelines (such as during overhauls or boiler start-up/shutdown) in the boiler’s high-temperature superheater system. The bush ring is installed on the sealing or contact surfaces between the block valve and the pipe, and is primarily used for sealing, wear resistance, and high-temperature protection at the connection point between the block valve and the superheater pipe.

Material of the Bush Ring: 38CrMoAlA

-

Material properties: 38CrMoAlA is a high-grade nitrided steel, belonging to the chromium-molybdenum-aluminum alloy steel series, with the following properties:

- High surface hardness: The surface hardness can reach HV950-1200 (approx. HRC65-70) after nitriding, offering excellent wear resistance.

- Good fatigue resistance: The nitride layer significantly improves the fatigue life of the part.

- Thermal stability: The nitride layer maintains high hardness below 600°C.

- Corrosion resistance: The addition of chromium and aluminum improves the material’s corrosion resistance.

- Good machinability: Easy to machine and weld.

-

Chemical Composition:

- Carbon (C): 0.35~0.42%

- Silicon (Si): 0.20~0.45%

- Manganese (Mn): 0.30~0.60%

- Phosphorus (P): ≤0.025%

- Sulfur (S): ≤0.025%

- Chromium (Cr): 1.35~1.65%

- Aluminum (Al): 0.70~1.10%

- Molybdenum (Mo): 0.15~0.25%

-

Mechanical Properties:

- Tensile strength (σb): ≥980 MPa

- Yield strength (σs): ≥835 MPa

- Elongation (δ5): ≥14%

- Area reduction (ψ): ≥50%

- Impact energy (Akv): ≥71 J

- Hardness: ≤229 HBW

-

Heat Treatment Process:

- Quenching: 940°C, water or oil cooling.

- Tempering: 640°C, water or oil cooling.