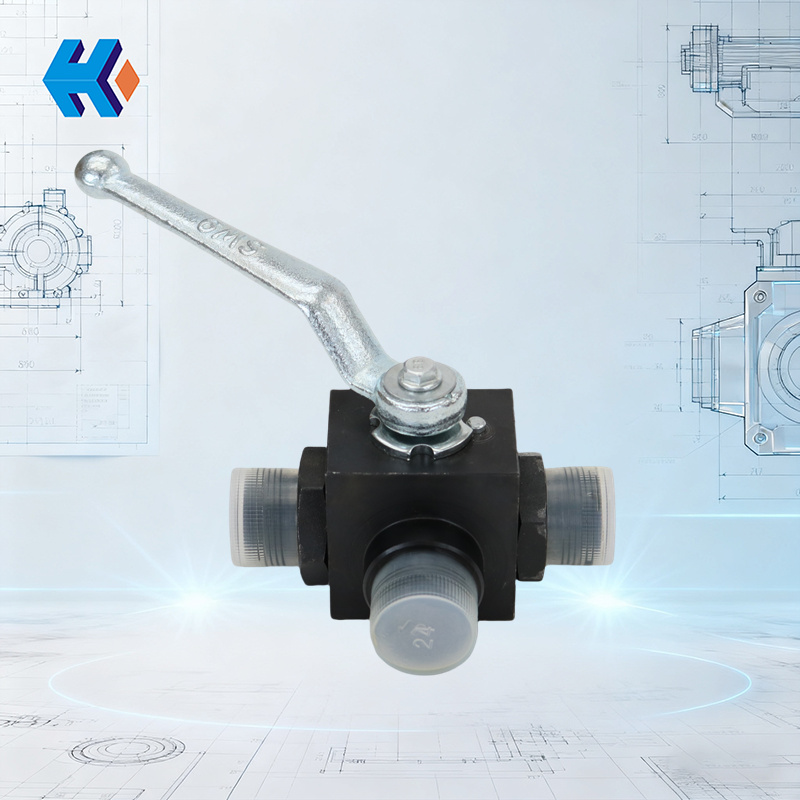

QJ-1.6MPa10L Three-way reversing Diverter valve

Unlock stable operation and precise fluid control in your induced draft (ID) fan oil station with the robust QJ-1.6MPa10L Three-way Diverter Valve. Learn how its high-strength construction and specialized design ensure long-term, corrosion-resistant performance.

1. Robust Design and Precision Functionality of the QJ-1.6MPa10L Valve

The QJ-1.6MPa10L 3-Way Diverter Valve is engineered for high-pressure fluid control, making it an indispensable part of industrial oil station systems, such as those governing large ID (Induced Draft) fans.

- Valve Body Construction: The valve body is typically cast from high-strength steel (often quality carbon steel) to provide excellent resistance against high pressure and corrosion. This robust construction ensures long-term, stable operation within the demanding environment of the blower oil station.

- Three-Channel Design: The interior of the valve body features three meticulously designed passages: the Inlet, the Outlet, and the Bypass Port. These three channels work in coordination to provide versatile control over the oil flow direction.

- Spool (Poppet) Operation: The valve spool acts as the critical moving component. Its precise movement within the valve body determines the open/closed state of the oil passages.

- Standard Connection: When the spool is in one specific position, the Inlet and Outlet channels are connected, allowing oil to flow smoothly from the Inlet to the Outlet. In this state, the Bypass Port is closed.

- Flow Diversion: When a change in oil flow direction is required, an external drive mechanism moves the spool to an alternate position. This action simultaneously cuts the connection between the Inlet and Outlet, opens the Bypass Port, and diverts the oil from the Inlet to the Bypass Port, effectively switching the flow path.

2. Specialized Materials for Durability and Leak Prevention

The longevity and reliability of the QJ-1.6MPa10L valve are guaranteed by the selection of high-grade materials tailored for industrial fluid dynamics:

- Valve Body: Constructed from high-quality carbon steel and treated with a special surface coating to significantly enhance its corrosion resistance.

- Valve Spool: Typically made from a wear-resistant, high-strength alloy. This selection ensures that the spool withstands frequent movement and switching cycles without excessive wear, guaranteeing the valve’s long-term stability.

- Sealing Components: High-performance materials, such as specialized rubber or elastomers, are used for seals. These materials offer exceptional sealing performance and oil resistance, effectively preventing fluid leakage and maintaining a tight seal under various operating conditions.

In summary, the QJ-1.6MPa10L valve’s blend of precision engineering and advanced material science delivers reliable, leak-free flow switching essential for the consistent performance of critical power plant machinery.

HKZX-2025-10-22