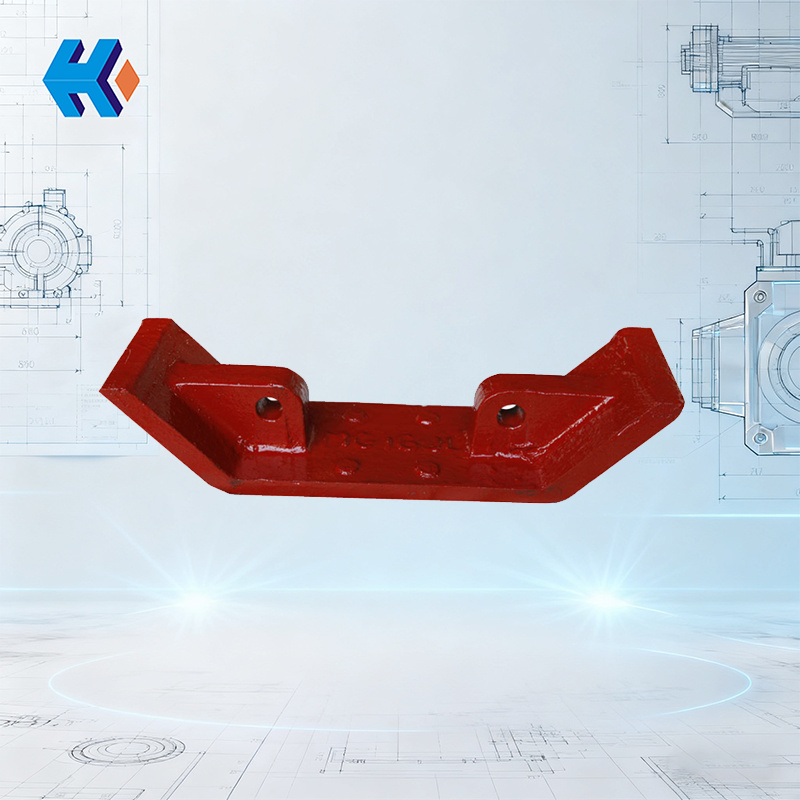

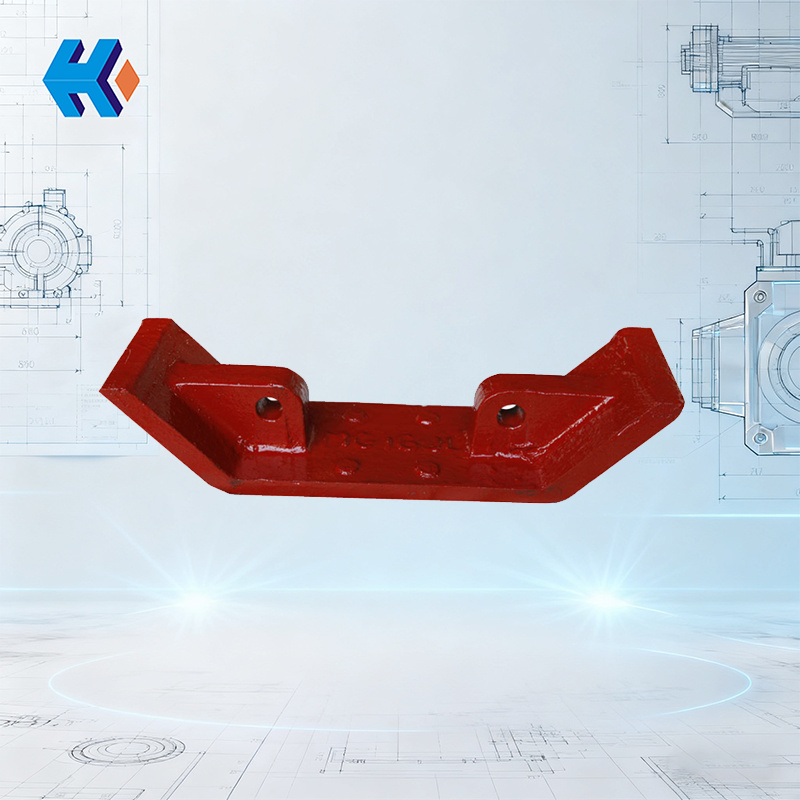

20MG40.11.09.72 coal mill Scuff wear Plate

Description of wear plate (1) 20MG40.11.09.72

The wear plate (1) 20MG40.11.09.72 is typically located in areas within the coal mill where coal powder flow is concentrated and abrasive forces are strong. It works in conjunction with wear plate (2) 20MG40.11.09.71 to provide comprehensive protection to the internal structure of the mill. It is closely positioned relative to components such as the mill casing and rotating nozzle ring. When coal powder is carried by primary air and moves in complex patterns, this wear plate is situated directly in the high-speed flow path, enduring continuous scouring and impact from the coal powder.

The primary function of wear plate (1) 20MG40.11.09.72 is to protect the underlying structure of the coal mill from excessive wear. In medium-speed coal mills, coal powder flows at high speeds internally, especially at corners or narrow passages where scouring forces intensify. Without the protection of wear plates, the casing and other base components would suffer from long-term wear, leading to wall thinning, deformation, or even cracking, which could affect normal mill operation. The wear plate sacrifices itself to protect these base components, significantly extending the mill’s overall service life and reducing maintenance frequency and costs.

The shape of wear plate (1) 20MG40.11.09.72 is adapted to the structure of the installation area, ensuring a tight fit with no dead zones in protection. Its connection method is carefully designed, possibly combining welding and bolting to ensure both secure attachment and ease of future replacement and maintenance. This design ensures that the wear plate remains firmly in place under long-term exposure to coal powder scouring and equipment vibration, without loosening or falling off, which could compromise its protective function.

Main functions of wear plate (1) 20MG40.11.09.72

Wear plate (1) 20MG40.11.09.72 requires regular inspection. Maintenance personnel can enter the mill interior through manholes or inspection doors to examine the wear extent, check for cracks, looseness, etc. Due to its specific location, the wear rate may be relatively high, so inspection frequency should be reasonably scheduled based on operating hours and coal powder characteristics. When obvious wear grooves appear, the thickness is reduced below the specified limit, or local cracking occurs, timely replacement is necessary. During replacement, ensure the new plate is properly installed and securely fastened to restore its protective function.

HKZX-2025-09-29-A