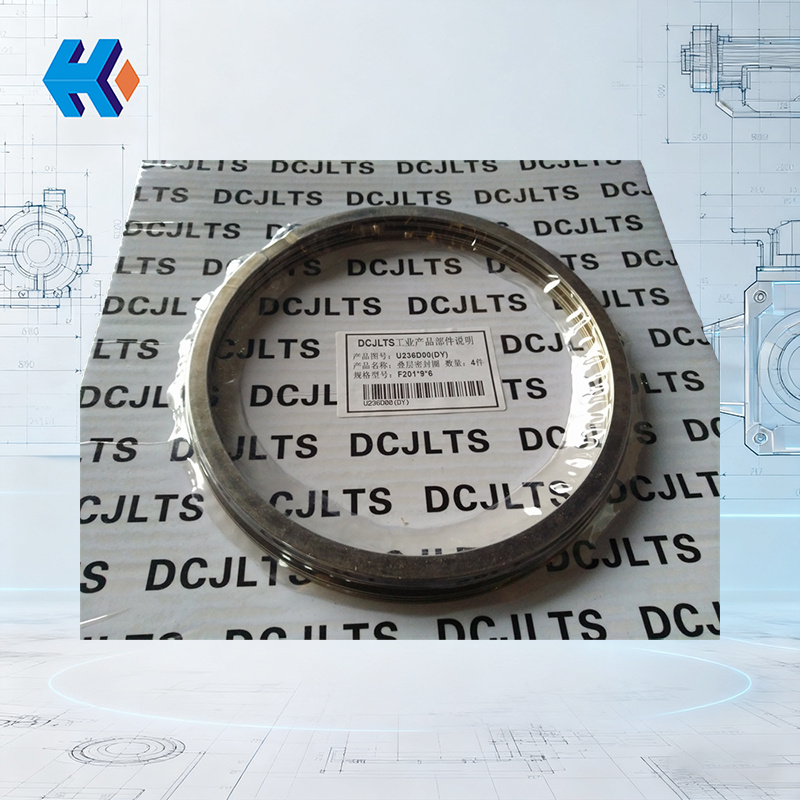

U236D00 (DY) Fan Laminated Seal Ring

Description of laminated seal ring U236D00 (DY)

The laminated seal ring U236D00 (DY) is typically composed of multiple layers of different materials working together to achieve optimal sealing performance. The innermost layer usually directly contacts the sealed component. This layer is made of materials with good conformability and flexibility, capable of tightly following the surface contours of the parts, effectively filling micro-gaps and preventing leakage paths from forming. The middle layer provides reinforcement and support, possibly using high-strength fiber fabric or metal mesh to maintain structural integrity under complex internal pressures and airflow impacts, preventing deformation or damage. The outer layer focuses on protection, using wear-resistant, corrosion-resistant, and weather-resistant materials to guard against external factors like dust, moisture, and corrosive gases, extending the seal’s service life. For example, some designs use a fluororubber outer layer due to its excellent chemical stability, effectively resisting erosion from various chemicals. The layers are tightly bonded through special processes, forming a stable and cooperative unit, ensuring reliable sealing performance throughout the long-term operation of the induced draft fan.

In some applications involving the blade root seals of induced draft fans, the laminated seal ring U236D00 (DY) can maintain a continuous sealing state under dynamic pressure environments during fan operation, preventing high-temperature, dust-laden gases from leaking through the blade root and ensuring efficient fan operation.

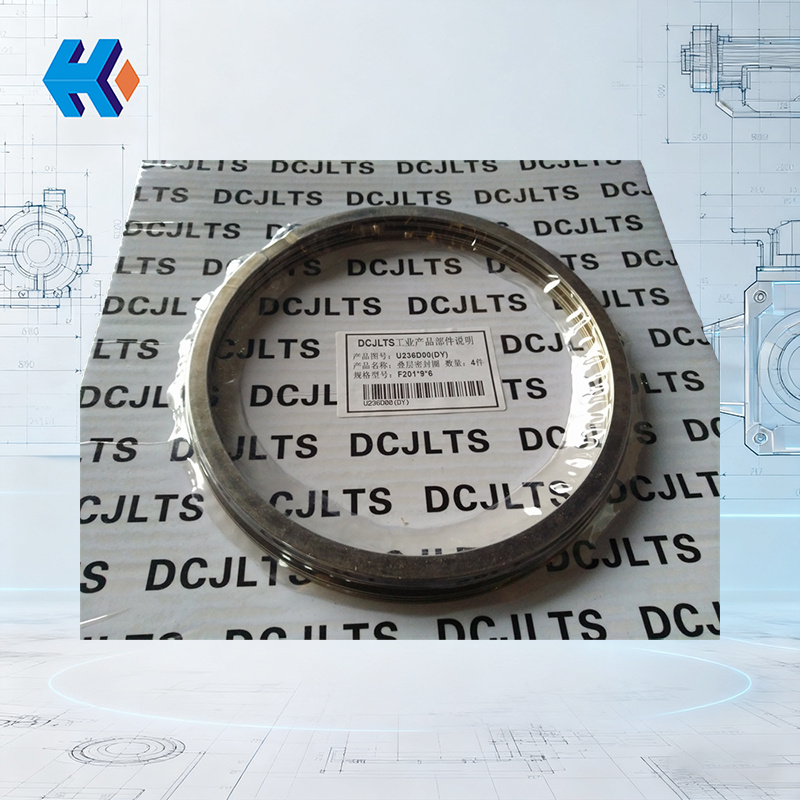

Application of laminated seal ring U236D00 (DY)

In the example of a thermal power plant’s induced draft fan, the high-temperature, high-dust, and corrosive flue gas produced by boiler combustion poses a significant challenge to sealing components. The U236D00 (DY) laminated seal ring, with its high-quality materials and rational structure, operates stably under such harsh conditions. It effectively prevents flue gas leakage, avoids environmental contamination, and prevents dust and impurities from entering the fan, reducing component wear and extending the overall service life of the fan. Under various operating conditions—whether during high-load operation with high internal pressure or during start-up and shutdown with pressure fluctuations—the seal ring reliably performs its sealing function, ensuring stable ventilation for the boiler and maintaining stable combustion.

HKZX-2025-09-29-A