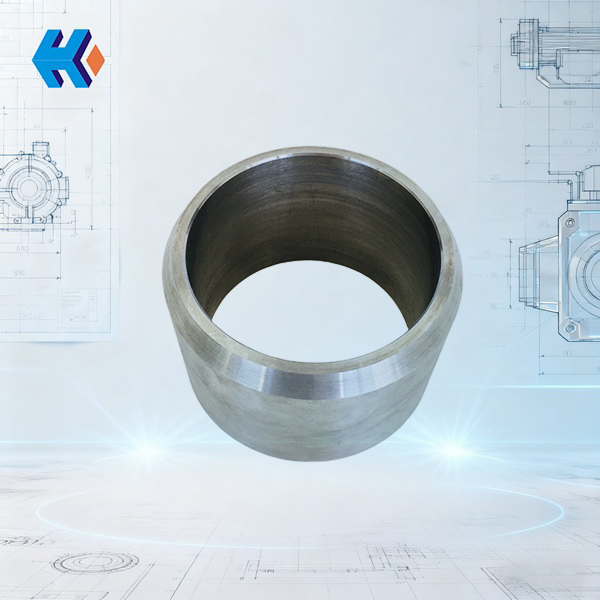

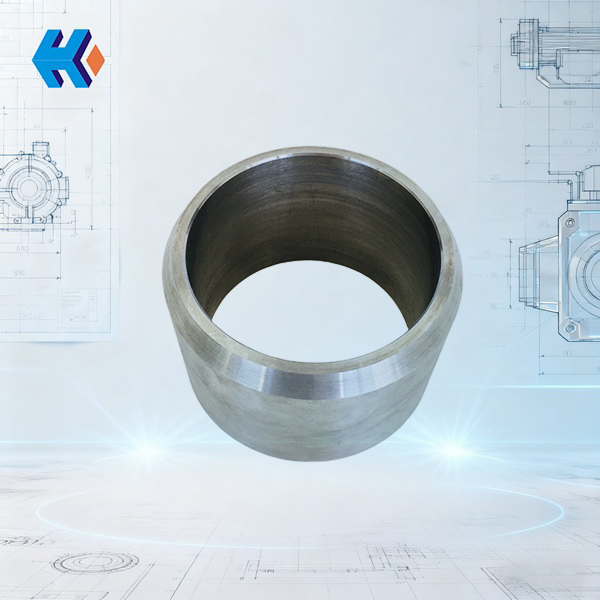

Dive into the Core Wear-Resistant Component for Boiler Booster Pump: Driven End Sleeve FA1D56-01-15

I. Product Overview: The Heart of the Booster Pump

The Driven End Sleeve for Boiler Feedwater Booster Pump, model FA1D56-01-15, stands as a pivotal, core wear-resistant component within the power plant booster pump system. It is absolutely crucial for ensuring the booster pump's stable operation and significantly extending the overall service life of the equipment.

Specifically engineered for the FA1D56A booster pump model, this sleeve performs vital functions in the power plant's steam-water cycle: sealing the shaft, minimizing shaft neck wear, and maintaining the pump's operational precision. It is an indispensable, mission-critical spare part during power plant overhauls, and a major focus for plants seeking a reliable component supplier.

From a product positioning perspective, the FA1D56-01-15 is far from a generic, off-the-shelf part. It is a highly specialized component custom-tailored to the specific operating conditions and structural characteristics of the FA1D56A booster pump.

Its design and manufacturing meticulously account for the demands of long-term, high-load, high-pressure, and complex media environments that power plant booster pumps face. This sleeve effectively counters typical issues like abrasion and corrosion during operation, providing a robust safeguard for the pump's safe and efficient performance.

Looking for proven reliability? Click here to secure your high-quality FA1D56-01-15 sleeves and elevate your pump reliability now!

II. Technical Features and Advantages: Performance Redefined

(A) Superior Material for Exceptional Wear Resistance

The driven End Sleeve is crafted from 1Cr17Ni2 material. This specific grade of stainless steel is selected for its outstanding mechanical properties, excellent corrosion resistance, and superior anti-wear capabilities. It enables the sleeve to withstand the impact of media scouring and mechanical friction in the demanding environment of the booster pump.

As a martensitic stainless steel, 1Cr17Ni2 offers high strength and hardness coupled with good toughness. This combination means the sleeve can absorb the inevitable shocks and vibrations during operation without succumbing to fracture or deformation. Utilizing this top-tier material fundamentally guarantees the sleeve's long-term durability, markedly reducing the risk of equipment failure due to sleeve wear, thereby lowering the frequency and cost of plant maintenance.

(B) Precision Manufacturing for Critical Dimensional Accuracy

Manufacturing the FA1D56-01-15 sleeve adheres to rigorous, high-standard production protocols, with extremely strict control over critical dimensions and surface finish.

For instance, the allowable deviation for the sleeve's diameter is tightly controlled within ±0.05 mm, and the ovality must not exceed 0.025 mm. This level of ultra-precision control ensures a perfect fit between the sleeve and the shaft neck, effectively eliminating operational issues like sealing failure or abnormal running noises that arise from excessive dimensional discrepancies.

Furthermore, the sleeve's surface finish achieves Ra (arithmetic average deviation of the profile) of 0.4–0.6 μm, or even better. This super-fine surface quality not only minimizes the friction coefficient between the sleeve and the stationary ring, reducing energy consumption, but also ensures the stationary ring glides smoothly over the sleeve surface. This prevents damage to the stationary ring that could be caused by excessive surface roughness, further enhancing the equipment's sealing performance and operational stability.

(C) Perfected Detail Processing for Reliable Safety

During production, great emphasis is placed on the meticulous finishing of the FA1D56-01-15, strictly ensuring that the sleeve surface is free of sharp edges or burrs. While seemingly minor, this detail is paramount to operational safety.

Since the stationary ring must pass over the sleeve surface, the presence of sharp edges or burrs could easily scratch the stationary ring during operation, leading to seal failure and, consequently, serious safety hazards such as media leakage. Through fine grinding and polishing processes, this sleeve achieves a smooth and even surface, providing a safe environment for the stationary ring's proper function. This detail significantly improves the operational safety and reliability of the entire booster pump system.

Don't compromise on safety! Contact our technical team today to discuss bulk orders and ensure zero-defect components for your next shutdown.

III. Application Scenarios: Where Reliability Counts

(A) Routine Operation and Maintenance of FA1D56A Booster Pumps

The FA1D56-01-15 sleeve is central to the daily operation of the FA1D56A booster pump. As a critical auxiliary unit in the steam turbine-generator's steam-water system, the booster pump pressurizes water from the deaerator before sending it to the feed pump. Its operational status directly impacts the efficiency of the entire generating system's steam-water cycle.

Working in concert with the shaft neck and stationary ring, the sleeve effectively minimizes shaft wear and maintains sealing integrity, ensuring the booster pump remains stable during long periods of continuous service. This prevents booster pump downtime caused by sleeve failure, thus safeguarding the power plant's normal generation schedule.

(B) Power Plant Overhaul and Replacement Scenarios

The FA1D56-01-15 is an essential replacement component during planned power plant maintenance or emergency repairs. Over extended operating periods, the sleeve will inevitably wear down due to friction and corrosion. When this wear exceeds specified tolerances, the sleeve must be replaced promptly to restore the equipment's performance.

As a sleeve professionally matched to the FA1D56A, it enables quick and perfect installation, drastically reducing overhaul time and minimizing generation losses due to equipment outage. For power plants prioritizing reliable spare parts, this sleeve, with its superior quality and stable performance, is a crucial choice for ensuring smooth maintenance and boosting post-overhaul operational reliability.

(C) New Power Plant Booster Pump System Integration

The FA1D56-01-15 is also a necessary complementary component for the installation and commissioning of booster pump systems in newly constructed power plants. New builds have the highest demands for component quality and performance, as this directly affects the long-term stability of the plant once operational. This sleeve meets stringent technical requirements and perfectly integrates with the FA1D56A booster pump, providing a reliable guarantee for the initial stable operation of the new system. It helps the plant successfully complete commissioning and lay a solid foundation for safe and efficient operation.

Related Recommended Spares

To ensure your FA1D56A Booster Pump operates at peak performance, we also highly recommend considering the following related critical spare parts, which are manufactured to the same high standards as the FA1D56-01-15 driven End Sleeve:

- FA1D56A Pump Shaft Sleeves (Other Positions): For comprehensive shaft protection.

- Stationary Rings / Mechanical Seal Kits (FA1D56A Specific): Essential for maintaining a perfect seal and maximizing sleeve life.

- FA1D56A Impeller Balancing Rings: Key components for vibration control and smooth running.

- High-Precision Thrust Bearings (FA1D56A Compatible): To handle axial loads and maintain rotor position accuracy.

Ensure complete pump reliability. Send your inquire today about our full spare parts kits for the FA1D56A Booster Pump!