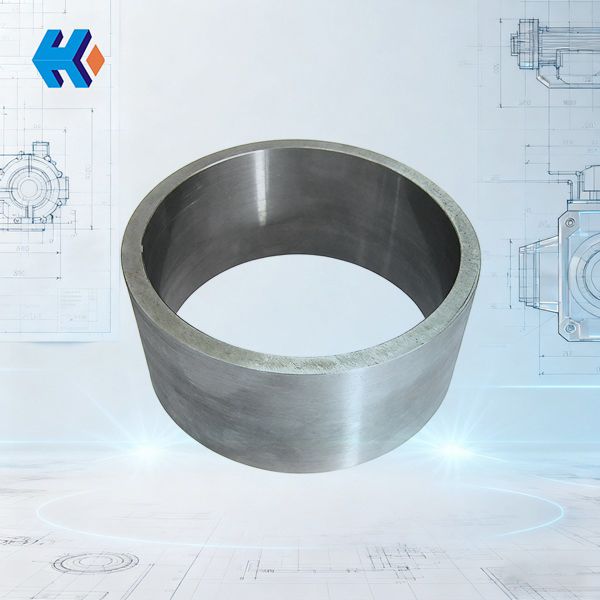

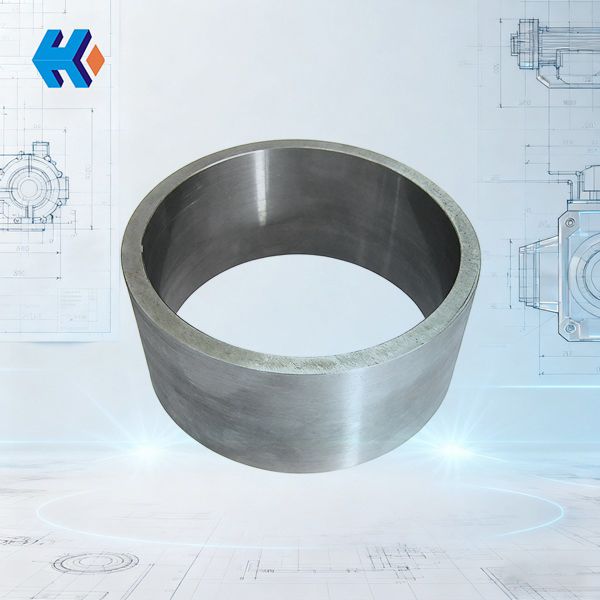

Inner End Shaft Sleeve FA1D56-01-06: Guarding the Core—Material, Heat Treatment, and Precision for FA1D56A Pump Reliability

I. Product Overview: Protecting the Pump Shaft

The Inner End Shaft Sleeve (Drive End), model FA1D56-01-06, is a critical, custom-designed component for the FA1D56A booster pump. Within the pump's transmission system, its vital roles include protecting the pump shaft (FA1D56A-01), drastically reducing shaft neck wear, and maintaining the equipment's running precision. It is classified as an essential wear part in the power plant booster pump unit.

This sleeve operates in collaboration with a complex array of other pre-pump components. During assembly and overhaul, it must interface perfectly with various sealing elements, such as the washers (FA1D56-03-21, FA1D56-03-24) and gaskets (FA1D56-03-09, FA1D56-02-04), to guarantee the internal sealing integrity of the pre-pump. Simultaneously, for structural stability, it works alongside fastening components during the installation of the main pump cover, including the hex nuts (FA1D56-03-14), cap nuts (FA1D56-03-18), and the main cover studs (FA1D56-03-13, FA1D56-03-19, FA1D56-03-20).

As a wear-prone yet crucial spare part during power plant overhauls, the quality of the FA1D56-01-06 sleeve directly impacts the operational stability and service life of the FA1D56A pump. For power stations seeking dependable suppliers, this part is a central point of focus. Its design and manufacturing strictly adhere to the operating conditions and structural needs of the FA1D56A, ensuring precise equipment compatibility and effective resilience against the complex media and sustained high-load environment, thereby securing the safe and efficient performance of the booster pump.

Need reliable shaft protection? Click here to learn how our FA1D56-01-06 sleeves can double your pump's lifespan!

II. Technical Features and Core Advantages

(A) Scientific Heat Treatment Process for Superior Mechanical Properties

The FA1D56-01-06 sleeve undergoes a specialized "quenching + tempering" heat treatment regime. Quenching temperature is meticulously controlled (e.g., 950–1000°C), with the cooling medium (e.g., water or oil) selected to ensure a uniform martensitic structure forms within the material. The subsequent tempering temperature (e.g., 200–300°C) is precisely regulated.

This process not only effectively relieves internal stresses induced by quenching but also results in a stable tempered martensite structure. This final structure combines high strength, high hardness, and excellent toughness, providing a robust foundation for the sleeve's wear resistance and impact resistance.

Compared to generic heat treatment methods, this process is rigorously validated and allows for precise tuning of the sleeve's mechanical properties to match the specific demands of the FA1D56A operation. It prevents issues such as increased brittleness and fracture from excessive hardness, or diminished wear resistance from insufficient hardness. This guarantees the sleeve can simultaneously resist mechanical friction and media scouring while enduring the inevitable impact and vibration loads throughout long-term operation.

(B) High Hardness Index for Outstanding Wear Resistance

The surface hardness of the FA1D56-01-06 sleeve is the primary indicator of its wear resistance. Testing confirms that the surface hardness is strictly maintained at HRC ≥ 40 (or equivalent HB ≥ 370 or HV ≥ 380). Hardness testing (e.g., Rockwell or Brinell method) focuses on key contact areas: the surfaces mating with the pump shaft (FA1D56A-01) and the areas contacting sealing components (FA1D56-03-09, FA1D56-02-04), ensuring critical zones meet hardness specifications.

This high hardness ensures that during prolonged operation with the pump shaft (FA1D56A-01), the sleeve significantly reduces shaft neck wear. Furthermore, its contact with sealing components results in lower frictional loss, noticeably extending the lifespan of both the sleeve and its complementary parts. This reduces the frequency and cost of power plant overhauls, strongly supporting the long-term stable operation of the FA1D56A pump.

(C) Precise Adaptability for Simplified Installation and Maintenance

The dimensional design of the FA1D56-01-06 sleeve strictly adheres to the structural parameters of the FA1D56A pump. It features a precise fit tolerance with the pump shaft (FA1D56A-01) and is perfectly compatible with all associated sealing components (FA1D56-03-21, FA1D56-03-24, FA1D56-03-09, FA1D56-02-04) and fastening hardware (FA1D56-03-14, FA1D56-03-18, FA1D56-03-13, FA1D56-03-19, FA1D56-03-20).

This high degree of precision not only simplifies the installation process during overhauls, reducing difficulty and minimizing errors caused by component mismatch, but also ensures the sleeve and all its mating parts work together effectively, boosting the pump's overall sealing performance and structural integrity. During replacement, maintenance personnel can execute quick, direct exchanges without needing to perform additional machining or adjustments to the sleeve or mating parts. This effectively shortens the overhaul cycle and reduces the economic impact of equipment downtime on power generation.

III. Application Scenarios: Where Performance Matters

(A) Routine Operation and Maintenance of the FA1D56A Booster Pump

In the daily operation of the FA1D56A, the FA1D56-01-06 sleeve is continuously active. It works closely with the shaft (FA1D56A-01) to protect it from damage caused by media scouring and mechanical friction. Concurrently, it collaborates with the sealing components (FA1D56-03-21, FA1D56-03-24, FA1D56-03-09, FA1D56-02-04) to maintain the pump's internal seal and prevent media leakage.

Given the FA1D56A's need for sustained, high-load operation in the steam-water cycle, the sleeve's exceptional wear resistance and stable mechanical properties enable it to withstand continuous operational stress, minimizing component degradation. This secures the pump's uninterrupted stable operation and ensures the efficient performance of the entire power generation system.

(B) Power Plant Overhaul and Replacement

During planned periodic overhauls or when the FA1D56A experiences a breakdown, the FA1D56-01-06 sleeve is a high-priority replacement spare part. If inspection reveals severe surface wear, reduced hardness, or cracking, immediate replacement is necessary to prevent the failure from escalating and damaging the pump shaft (FA1D56A-01) and other associated components.

The replacement process involves removing the main pump cover fasteners (FA1D56-03-14, FA1D56-03-18, FA1D56-03-13, FA1D56-03-19, FA1D56-03-20). Once the cover is off, the worn sleeve (FA1D56-01-06) is replaced, and the sealing components (FA1D56-03-21, FA1D56-03-24, FA1D56-03-09, FA1D56-02-04) are simultaneously checked and replaced to restore the pump to excellent operating condition. Timely supply and precise fit of this core product from a reliable vendor effectively shorten the overhaul cycle, minimizing economic losses resulting from equipment downtime.

(C) FA1D56A Assembly and Modification Projects

For assembling new FA1D56A pumps in greenfield power stations, or during the upgrade and modification of older units, the FA1D56-01-06 sleeve is an essential core component. During assembly, the sleeve is precisely fitted onto the pump shaft (FA1D56A-01), followed by the installation of the sealing parts. The entire assembly is then secured using the main cover studs and nuts, ensuring the overall structural integrity and stability of the booster pump.

In modification projects, upgrading to a high-quality FA1D56-01-06 sleeve significantly improves the older pump's wear resistance and running precision, extending the equipment's overall lifespan and reducing future maintenance costs. This helps the power station achieve its goals for equipment modernization and efficient operation.

Related Recommended Spares

To secure the sealing integrity and stability of the Drive End Shaft, we strongly recommend a full inventory of these related components:

- Gaskets (FA1D56-03-09 & FA1D56-02-04): Direct mating seals; crucial for preventing media leakage around the sleeve.

- Washers (FA1D56-03-21 & FA1D56-03-24): Essential for proper load distribution and sealing compression.

- Main Cover Fastener Sets (FA1D56-03-13, -19, -20 Studs, FA1D56-03-14 Nuts): The primary structural components ensuring the sleeve and seals are properly retained.

- Pump Shaft (FA1D56A-01): As the mating part, maintaining its integrity is paramount to maximizing sleeve life.

Ensure your inventory is complete! Contact us today for a full sealing and fastening kit compatible with the FA1D56-01-06 sleeve.