Solving Low Header Oil Pressure: Addressing Internal Leakage in ID Fan Servo Valve HU25042-221G

Solving Low Header Oil Pressure: Addressing Internal Leakage in ID Fan Servo Valve HU25042-221G

In the maintenance of adjustable-blade axial flow Induced Draft (ID) fans in thermal power plants, "Internal leakage in the ID Fan Servo Valve leading to low header oil pressure" is a high-frequency pain point. This not only violates the requirements of DL/T 748.5-2001 (Guidelines for Overhaul of Boiler Units in Thermal Power Plants), which mandates "hydraulic system oil pressure fluctuation pm 0.2 MPa," but also risks cascading issues like control vane regulation failure and abnormal fan current.

Today, leveraging practical experience, we discuss how to use the ID Fan Servo Valve HU25042-221G to resolve internal leakage and stabilize the hydraulic oil station's main header oil pressure.

I. Internal Servo Valve Leakage: 3 Typical Problems of Unstable Header Pressure

The servo valve is the "control core" of the ID fan's hydraulic regulation system. If internal leakage occurs (e.g., spool wear, aged seals), high-pressure oil bypasses from the P-port to the T-port, directly destabilizing the oil pressure. The three common issues are:

- Sustained Low Header Oil Pressure: Internal leakage causes "invisible loss" of pressure oil. The pump's make-up rate cannot keep up with the leakage rate, dropping the pressure from the design value (e.g., 3.5MPa) to below 3.0 MPa. This triggers frequent starting of the standby pump, creating a vicious cycle of "make-up – leak – re-make-up."

- High-Frequency Oil Pressure Oscillation: If the leakage gap within the servo valve is non-uniform, the oil pressure will repeatedly fluctuate between 2.8 MPa and 3.6MPa. This causes delays in vane regulation, or, as seen in a case study from a power plant in Jiangxi, "sudden spikes and drops in ID fan current," indirectly increasing the risk of a Manual Fan Trip (MFT).

- Increased Oil Temperature Accelerates Degradation: To compensate for internal leakage, the oil pump operates long-term under high load. The hydraulic oil temperature rises by 5-8^\circ C, accelerating oil degradation, which in turn scores the servo valve spool. This is the root cause of the "worsening leakage" phenomenon in ID Fan Servo Valves.

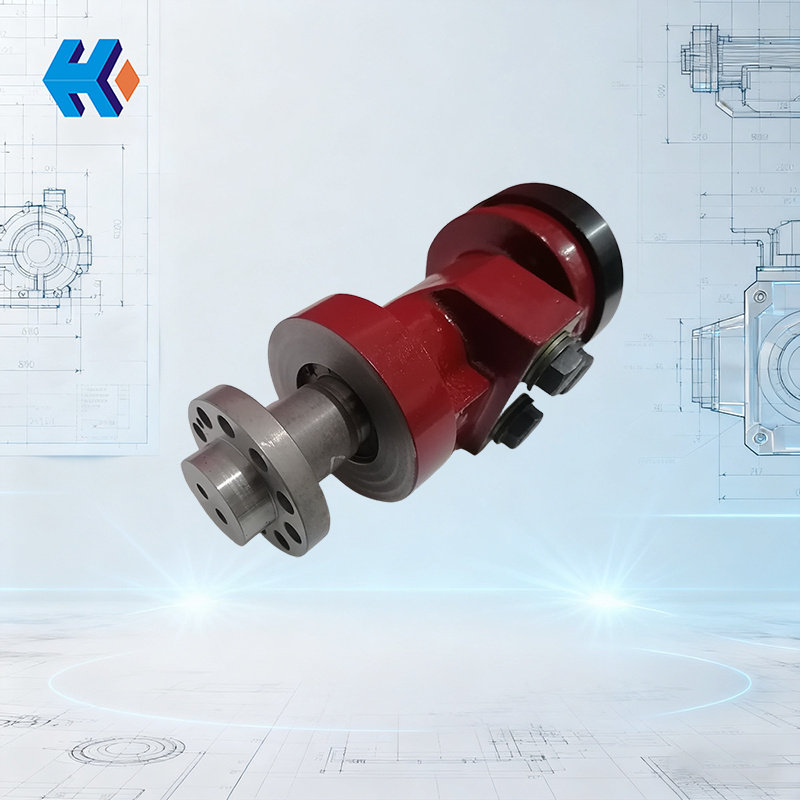

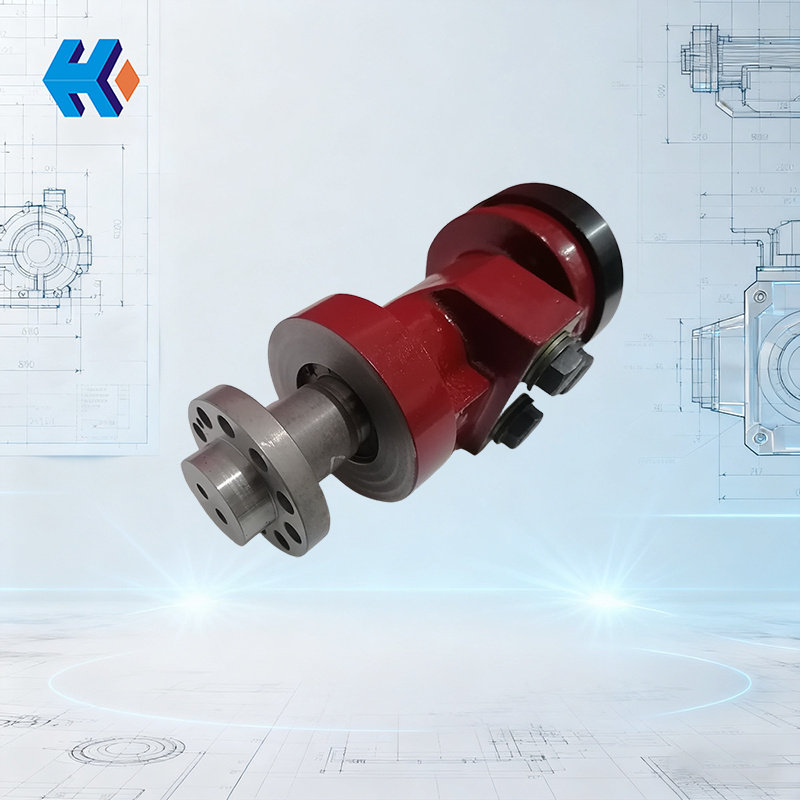

II. ID Fan Servo Valve HU25042-221G: Solving Internal Leakage at the Source

The ID Fan Servo Valve HU25042-221G is specifically designed for AP/TLT type adjustable-vane fans. It precisely meets the DL/T 748.5-2001 standard and is structurally engineered to prevent internal leakage:

- Dual-Seal Anti-Bypass Design: Utilizes the ID Fan Servo Valve Seal MFD-HU25042-22 made of Fluorocarbon rubber, paired with a high-precision fit between the spool and sleeve (0.01 - 0.02 mm). The internal leakage rate is controlled to \le 0.5 L/min, significantly lower than the 1 - 2L/min internal leakage of conventional industry servo valves, thus reducing pressure loss at the source.

- Anti-Contamination Design Reduces Wear: The oil channels within the valve body are mirror-polished. Paired with the Filter Element HU25042-2G (filtration precision 10 \mu m, ensuring hydraulic oil cleanliness NAS} \le 7), this design prevents contaminants from scoring the spool, extending the service life of the HU25042-221G to over 50,000 hours.

In a real-world application, a 600 MW unit that replaced its servo valve with the HU25042-221G saw header oil pressure fluctuation drop from 0.5 MPa to 0.15 MPa, fully meeting the guideline requirement. The standby pump start count reduced from an average of 12 times per day to zero.

III. System Spares: Synergistic Action with HU25042-221G to Build a Pressure Defense Line

Solving servo valve internal leakage requires a system approach, not just replacing the valve. Coordinated action with related spares is necessary:

- Smooth Vane Regulation: The ID Fan Adjustable Vane HU25042-22 and Blade HU25042-22G use wear-resistant Q345D material. Fastened with the Blade Bolt HU25042-551G (or YFJ-YPLS-HU25042-22), they reduce vane regulation resistance, lowering the load on the HU25042-221G.

- Long-Life Kinematic Pair Lubrication: The ID Fan Spindle Copper Sleeve YFJ-XZTT-HU25042-22 is made of tin bronze. Paired with the Seal Ring HU25042-222G, it reduces transmission component wear, preventing the servo valve from being "forced to leak internally" due to actuator sticking.

- Precise Transmission: The ID Fan Transmission Slider YFJ-HK-HU25042-22 undergoes surface hardening, reducing the friction coefficient by 30%. This ensures the servo valve's commands are precisely transmitted to the vanes, further stabilizing oil pressure.

IV. Operational Tips: Maintenance Essentials for ID Fan Servo Valve HU25042-221G

As required by DL/T 748.5-2001, daily maintenance should focus on two points:

- Internal Leakage Detection: Weekly check the hydraulic oil station return oil temperature. If the return oil temperature is > 5circ C higher than the supply oil temperature, and header oil pressure fluctuation exceeds pm 0.2 MPa, the ID Fan Servo Valve HU25042-221G should be disassembled and inspected. The Seal MFD-HU25042-22 should be the focus for signs of aging.

- Scheduled Replacement: It is recommended to replace the Filter Element HU25042-2G every 3 months. The ID Fan Servo Valve HU25042-221G should undergo precision calibration every 2 years to ensure the internal leakage rate remains \le 0.5 L/min.

The ID Fan Servo Valve HU25042-221G not only solves internal leakage and stabilizes oil pressure but also comes with a full range of compatible spares, complying with the DL/T 748.5-2001 standard. It is your key to achieving "zero forced outage" operation for your thermal power plant ID fan!

HKZX-2025-10-28