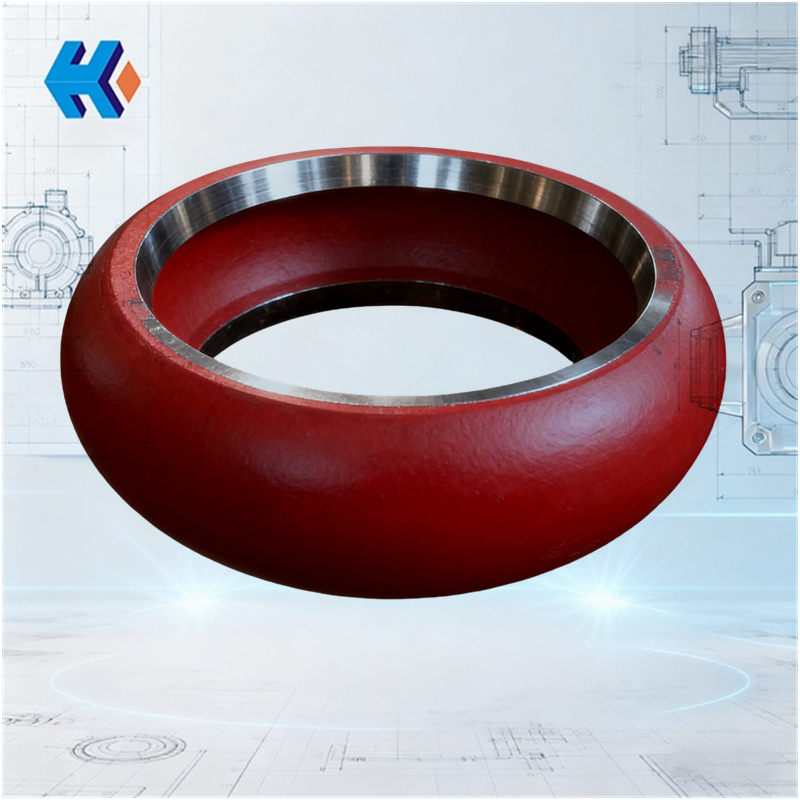

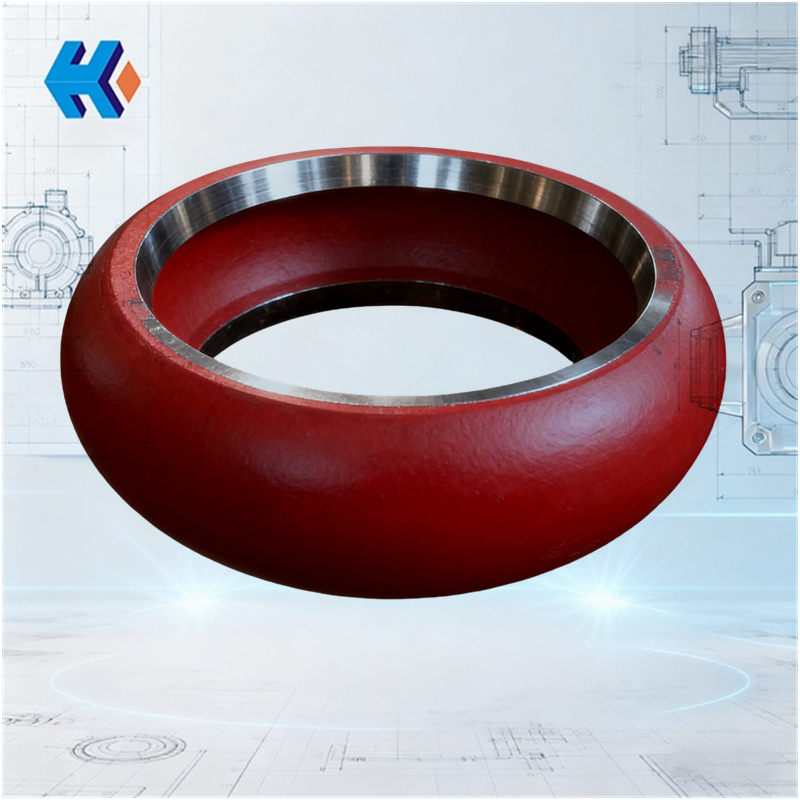

Medium-Speed Pulverizer Composite Grinding Roller Sleeve 20MG53.11.09.99

In coal-fired power plants, medium-speed mill roller sleeves frequently suffer from premature wear—often requiring replacement after only 4,000 hours due to intense grinding and silica erosion. This falls significantly short of design expectations.

I. Root Causes of Abnormal Roller Sleeve Wear

Based on DL/T 838-2017 guidelines and operational data from over 30 plants, we address the three primary killers of sleeve longevity:

- Material Mismatch: Traditional high-chrome iron spalls rapidly when coal abrasion values exceed 3.5.

- Impurity Impact: Rocks and tramp metal escaping iron removers cause local cracking.

- Operational Stress: High-load operation and excessive primary air accelerate surface erosion.

II. 20MG53.11.09.99-DH Technical Solution

Our composite sleeve addresses these issues via material science and metallurgical bonding.

1. Technical Parameters for High-Abrasion Coals

| Parameter Category | Specific Index | Advantage |

|---|---|---|

| Wear Layer Material | Ni-Cr-Mo-V High Alloy | Resistance improved by over 40%. |

| Surface Hardness | HRC 62-65 | Resists extremely high-abrasion silica. |

| Matrix Toughness | QT600 Ductile Iron | Inhibits crack propagation from impacts. |

| Designed Lifespan | 18,000 Hours | Meets two Class-A overhaul cycles. |

2. Dual-Metal Casting Process

The 20MG53.11.09.99-DH uses centrifugal casting to ensure a uniform alloy distribution in the wear layer, which is then metallurgically bonded to a ductile iron matrix for maximum impact strength.

III. Extended ZGM Series Spares Support

Dongfang SRI provides a full spectrum of ZGM series components to ensure mill availability:

| Product Name | Part Number |

|---|---|

| Deflector Ring/Guard | MG40.11.09.03 |

| Upper Tie Rod | 21MG40.11.13.99 |

| Lower Tie Rod | 21MG40.11.13.96 |

| Guide Plate I & II | 20MG40.11.12.07.94 / 99 |

| Liner Plate Bolting Set | MG43.11.08.94 |

| Roll Oil Seal Support Ring | 20MG40.11.09.83 |

| Scraper Assembly | 20MG40.11.07.01J |