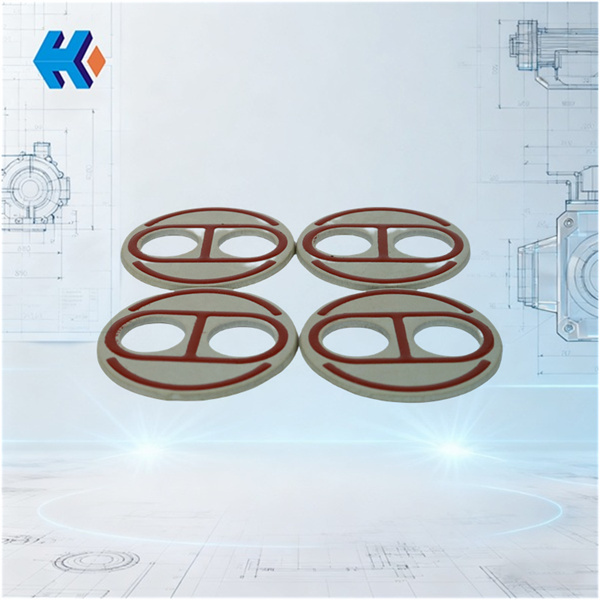

Servo Valve Gasket DTYD30TY008: A Critical Sealing Component

The Servo Valve Gasket DTYD30TY008 is a critical sealing element used in hydraulic servo valve systems. Its function is to prevent hydraulic fluid leakage in high-pressure working environments while ensuring the stable operation and precise control of the servo valve. This gasket is widely applied in fields requiring extremely high sealing performance, such as aerospace, industrial automation, and precision mechanical control.

I. Structure and Material Characteristics

The Servo Valve Gasket DTYD30TY008 typically adopts a composite structure design, consisting of multiple layers of sealing materials with different hardnesses.

• The inner side uses a high-hardness material to withstand mechanical stress under high-pressure conditions.

• The outer side uses a low-hardness material to enhance conformity with the valve body surface, ensuring sealing effectiveness even at low pressures.

This combined high/low-pressure structure effectively solves the problem of insufficient adaptability of traditional single-material gaskets across varying high and low-pressure operating conditions.

Material Selection

In terms of materials, this gasket often uses oil-resistant, high-temperature-resistant specialty rubber or Polytetrafluoroethylene (PTFE) composite materials. For instance, Nitrile Butadiene Rubber (NBR) and Fluoroelastomer (FKM) are frequently used in hydraulic system sealing components due to their excellent oil and temperature resistance. These materials can maintain stable physical properties over long periods in high-pressure, high-temperature environments and resist chemical corrosion from the hydraulic fluid, thus extending the gasket's service life.

II. Working Principle

The working principle of the Servo Valve Gasket DTYD30TY008 is based on its unique composite structure and material properties.

During servo valve operation, the hydraulic system generates alternating high and low-pressure conditions.

• The high-hardness inner section of the gasket can withstand high-pressure shock, preventing hydraulic fluid leakage from the central part of the valve body.

• The low-hardness outer section, through greater compression, ensures good sealing performance is maintained even under low-pressure or static pressure-holding conditions.

This design not only enhances the sealing effect but also reduces the risk of sealing failure caused by pressure fluctuations.

III. Performance Advantages

• High Pressure and High Temperature Resistance: The gasket maintains stable sealing performance in high-temperature and high-pressure environments, adapting to the complex working conditions of servo valves.

• Excellent Corrosion Resistance: Its materials possess outstanding oil and chemical corrosion resistance, effectively resisting chemical attack from hydraulic fluid components and ensuring long-term reliability.

• Dual High/Low-Pressure Sealing: Through the composite structure design, the gasket provides reliable sealing under both high and low-pressure conditions, significantly improving the overall performance of the servo valve.

• Simple Structure, Economical and Practical: Compared to other complex sealing devices, the DTYD30TY008 gasket features a simple design, low manufacturing cost, and high maintenance convenience.

IV. Application Scenarios

The Servo Valve Gasket DTYD30TY008 is widely utilized in hydraulic servo systems that require high-precision control, such as:

• Hydraulic control units in aerospace vehicles.

• Precision hydraulic systems in industrial automation equipment.

• Hydraulic power units in construction machinery.

Its excellent sealing performance and durability make it an indispensable key component in these fields.

V. Installation and Maintenance Notes

• Installation Requirements: When installing the DTYD30TY008 gasket, ensure it is fully seated against the valve body surface to prevent sealing failure due to improper installation. Additionally, avoid excessive installation torque to prevent damage to the gasket's structure.

• Regular Inspection: It is recommended to regularly check the condition of the gasket, especially after prolonged operation under high-temperature and high-pressure conditions. Check for signs of aging, deformation, or cracking. Any detected issues should lead to immediate replacement.

• Replacement Standard: The DTYD30TY008 gasket is a consumable item. If a decline in sealing performance or material aging is observed, it should be replaced immediately to avoid impacting the normal operation of the servo valve.

We can provide more fan parts below:

|

servo valve |

TY9100 |

|

Cylinder group connecting rod |

TY98010 |

|

Double sealing ring 2 for oil cylinder |

TY9110C |

|

Oil cylinder scraper ring 2 |

TY9111C |

|

Oil cylinder gasket |

TY9112C |

|

servo valve |

ty9100b-f |

|

Servo valve gasket |

GU23838-22 |

|

servo valve |

GU13832-01 TY9100 |

|

servo valve |

HU25242-22G TY9100B |

|

bearing |

2JJQ52 |

|

Bearing inner ring |

2YZG52 |

HKZX-2025-11-07