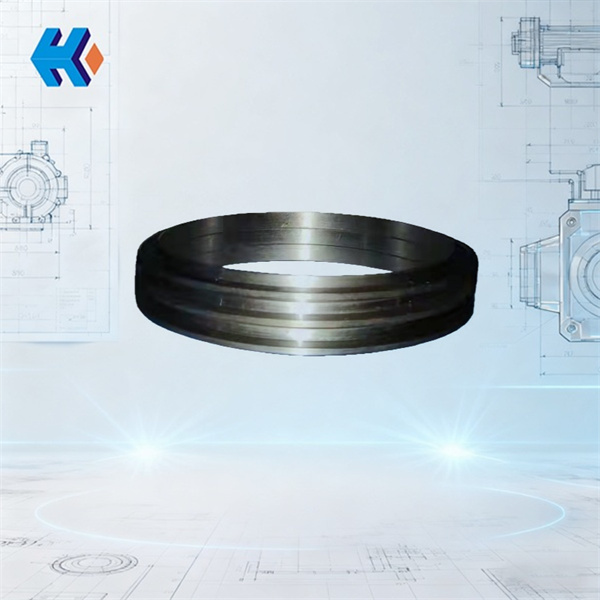

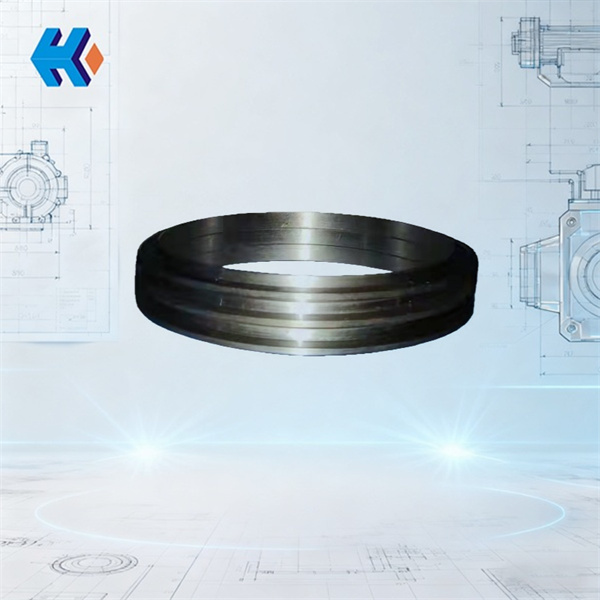

Technical Specifications: Oil Seal Support Ring 20MG40.11.09.83J

The Oil Seal Support Ring 20MG40.11.09.83J is a specialized structural component designed for the sealing system of ZGM series medium-speed pulverizers. It is specifically engineered for the roller assembly of the ZGM123G model. Working in coordination with the roller skeleton oil seal and the Shaft Sleeve (20MG50.11.09.84J), it is installed between the Roller Bracket (20MG40.11.09.98) and the roller shaft system to provide positioning, rigid support, and auxiliary sealing functions.

I. Product Overview

The sealing system is a critical protection zone of the pulverizer, required to withstand high lubricant temperatures and the abrasive force of coal dust. As the foundational support for the oil seal, the precision of this ring directly impacts the overall effectiveness of the sealing system.

-

Manufacturing Standards: Fabricated according to GB/T 700-2006 (Q235A).

-

Material & Process: Made from high-quality Q235 steel through precision stamping, deburring, and electro-galvanization.

-

Quality Assurance: Finished products are free from cracks, dents, or burrs, featuring a uniform, rust-resistant surface.

-

System Synergy: It works alongside the Protective Cover (20MG40.11.09.03J) and the Roller Breather (20MG40.11.09.01j) to build a multi-layer defense for the roller shaft and lubrication system.

II. Technical Features and Advantages

| Feature | Description | Operational Benefit |

| High Material Strength | Made from Q235A steel with tensile strength of 375-500MPa. | Resists vibration loads and assembly pressure without deformation, preventing oil seal misalignment. |

| Precision Stamping | Tight dimensional tolerances matching original equipment (OEM) standards. | Ensures a seamless fit with the roller bracket and shaft sleeve, eliminating assembly gaps. |

| Surface Treatment | Advanced electro-galvanization process. | Provides superior corrosion resistance in humid and dusty environments, extending the spare part's service life. |

| Anti-Damage Design | Comprehensive deburring of all sharp edges and corners. | Prevents scratching of the oil seal lips or shaft sleeve surfaces during installation, ensuring seal integrity. |

III. Application Scenarios

The Oil Seal Support Ring is vital during the assembly, routine maintenance, and overhaul cycles of ZGM123G pulverizers in thermal power plants and industrial coal-processing facilities.

1. Routine Maintenance (Every 1,000 Operating Hours)

During periodic inspections, technicians check the support ring for signs of corrosion, deformation, or cracks. The alignment between the ring, oil seal, and shaft sleeve is verified. If displacement or severe surface oxidation is found, the ring must be replaced to prevent uneven stress on the oil seal, which could lead to lubricant leakage.

2. Major Overhaul (3,000–4,000 Operating Hours)

When the pulverizer undergoes a full disassembly due to vibration anomalies or scheduled maintenance, the support ring is evaluated for replacement.

-

Note: If the Wear Plates (138MG40.11.09.72j/71j) are replaced during an overhaul, the support ring’s position must be re-calibrated to ensure it sits flush against the roller bracket.

3. Emergency Troubleshooting & Fault Handling

In the event of a failure in the Hydraulic Directional Valve (MG00.11.19.01) or excessive coal dust ingress due to worn Scraper Blades (20MG33.11.07), the support ring may be subjected to abnormal loads or abrasive flushing. In such cases, the ring must be inspected for structural integrity. Replacing a damaged support ring promptly prevents secondary damage to the shafting caused by lubricant contamination.

IV. Procurement and Maintenance Advice

For plant engineers and procurement departments, it is recommended to:

-

Verify Material Certification: Ensure the Q235A material complies with GB/T 700-2006 for guaranteed yield strength.

-

Ensure Component Synergy: Source the support ring together with its matching oil seals and shaft sleeves from a professional supplier to ensure 100% compatibility.

-

Strict Installation Protocol: During assembly, ensure the mounting surface is cleaned of all rust and debris. Use professional tools to ensure the ring is seated perpendicularly to the shaft axis to avoid "cocking" the oil seal.

HKZX-2026-01-23