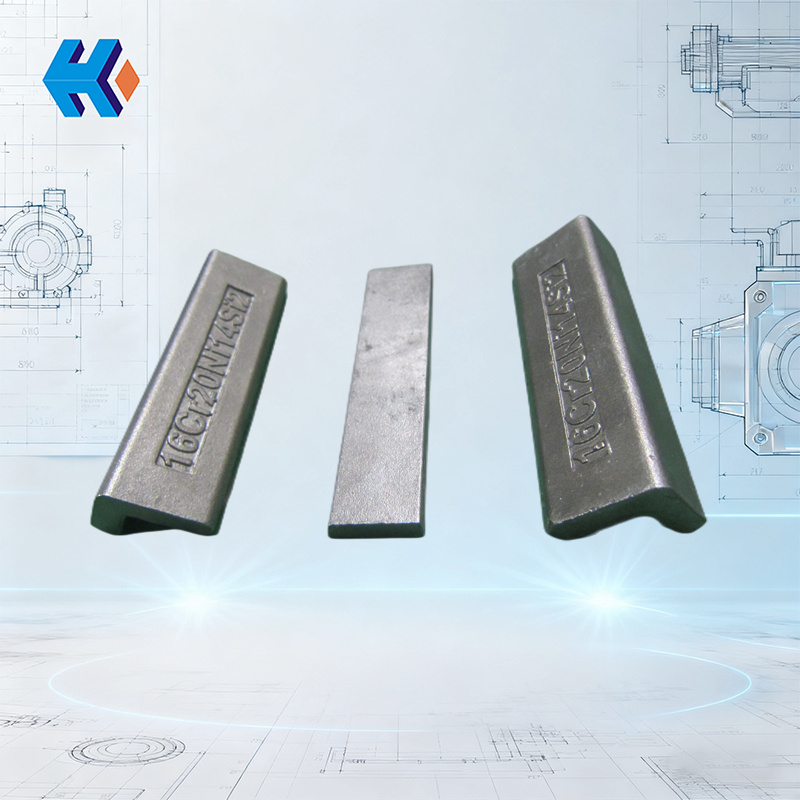

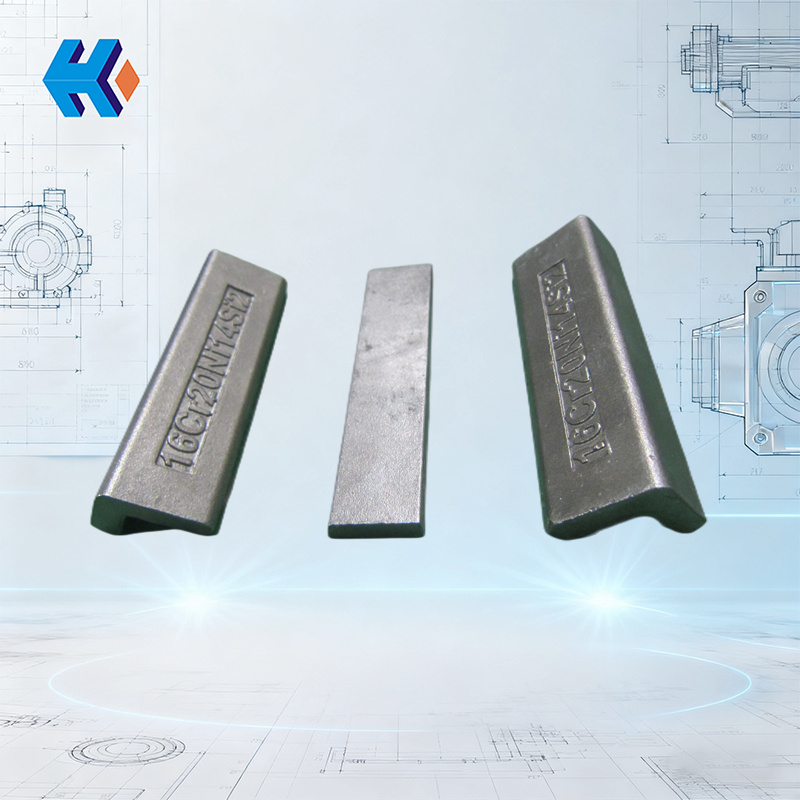

Superheater Sliding Block ZG1Cr20Ni14Si2- Power Plant Boiler Anti-Seize Support and Positioning Component

The boiler superheater system operates under severe conditions characterized by high temperature, high pressure, steam erosion, and thermal expansion displacement. Components such as sliding blocks, desuperheater parts, and piping auxiliaries are prone to wear, deformation, and sealing failure, which directly impacts steam temperature regulation precision and piping safety.

Focusing on the maintenance pain points of superheater systems, utilizes premium material selection and precision processing to create highly adaptable and durable core spare parts. These parts fully meet the operation and maintenance (O&M) requirements for superheater systems and water-steam piping in 300-1000MW units.

1. Product Overview

-

Superheater Sliding Block: A specialized support and positioning component for superheater piping. It accommodates axial and lateral thermal expansion displacement, limits excessive vibration, and prevents impact wear between pipes, brackets, and furnace walls.

-

Superheater Secondary Desuperheater Mixing Tube: The core component of the secondary desuperheating system. It ensures thorough mixing of desuperheating water and high-temperature steam to precisely regulate steam temperature.

-

Superheater Shield (Protective Cover): A dedicated protective component for pipes and fittings. It covers areas susceptible to fly ash erosion and flue gas corrosion, extending the service life of superheater components.

-

Superheater Primary Desuperheater Mixing Tube: The core steam-water mixing part for the primary desuperheating system, providing initial temperature regulation and reducing the heat load on the superheater heating surface.

-

Superheater Primary Water Spray Pipe: Injects atomized desuperheating water into the steam pipe, laying the foundation for full mixing and improving desuperheating efficiency.

-

Alloy Steel 90° Elbow: A redirection component for high-temperature steam/water piping. Made of heat-resistant alloy steel, it withstands the pressure and erosion loads of high-temperature steam.

-

Constant Force Spring Support & Hanger: Provides a constant supporting force to accommodate piping displacement caused by thermal expansion, balancing pipe gravity and preventing deformation due to thermal stress.

-

Constant Force Disc Spring Compensator: Compensates for axial/radial displacement caused by temperature changes and absorbs piping vibrations to ensure sealing and structural stability.

2、 Product Features

| Product Name | Core Material | Core Function | Key Characteristics |

| Superheater Sliding Block | ZG1Cr20Ni14Si2 (Austenitic Heat-Resistant Steel) | Support and positioning; accommodates thermal expansion. |

1. Resists temperatures above 800°C; excellent oxidation and wear resistance. 2. Ground sliding surface with low friction coefficient; no sticking. 3. High dimensional precision for easy installation. |

| Secondary Desuperheater Mixing Tube | SA-213 T91 (Martensitic Heat-Resistant Steel) | Thorough steam-water mixing for precise temperature control. |

1. Resists 650°C/≤42MPa; suitable for high-pressure steam. 2. Built-in flow guide ribs to eliminate temperature deviation. 3. Uniform wall thickness with high resistance to steam erosion. |

| Superheater Shield | SA-240 GR309S (Heat-Resistant Stainless Steel) | Protects against fly ash erosion and flue gas corrosion. |

1. Resists temperatures over 1100°C. 2. Mold-pressed for a precise fit with protected parts. |

HKZX-2026-01-28