Steam Turbine Pressure Regulator Slide Valve

The pressure regulator slide valve is a key character in the steam turbine's regulating system. Although it is small, it is the "nerve center" that connects the unit's signals with the actuators. It directly relates to whether the steam turbine can carry a stable load and respond quickly to grid changes.

I. What exactly is it?

Simply put, the core task of the pressure regulator slide valve is one: to "translate" signals and drive actions. When the steam turbine's speed or load changes, it can quickly capture these signals. Then, through the slight movement of its own valve core, it precisely controls the amount of high-pressure oil entering the oil motor. When the oil motor acts, the steam turbine's regulating valve can open and close, ultimately achieving the regulation of steam intake. This is like a car's accelerator pedal: a slight movement causes the power to change accordingly.

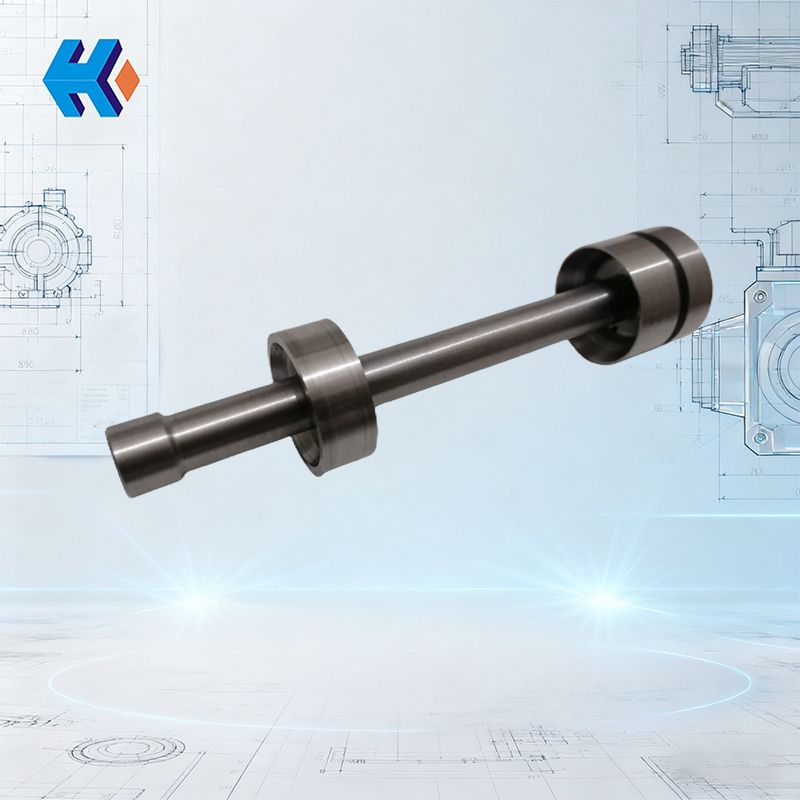

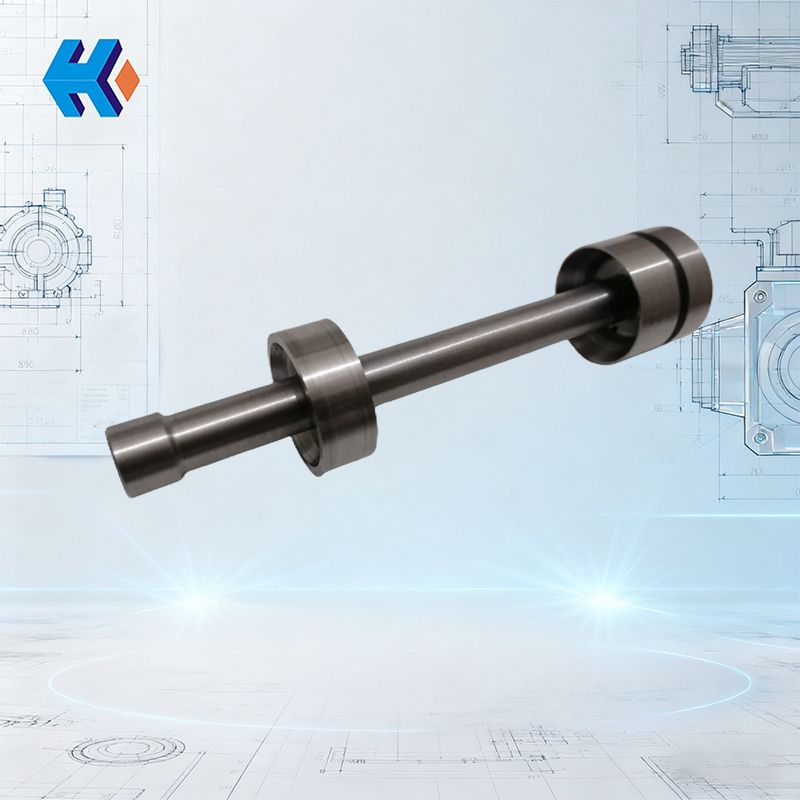

II. What does it look like? What are its core structures?

Let's dissect it. It is mainly composed of these parts:

- Valve Core: Like a small stepped column, its surface is ground to be even brighter than a mirror (roughness can reach Ra0.4μm). This is key to ensuring accuracy.

- Valve Sleeve: The valve core slides inside it, and the fit clearance between the two is only 0.005-0.01mm (thinner than a hair). This ensures oil does not leak randomly.

- Feedback Spring: Can "return" automatically according to pressure, making regulation more stable.

These parts together form a "high-precision hydraulic switch".

III. What "hard indicators" must it meet?

In a steam turbine, it must withstand these tests:

- Fast Response: When the grid load changes, it must react within 0.1 seconds, otherwise the unit will "fall behind".

- High Precision: When the valve core moves 1 millimeter, the action error of the oil motor cannot exceed 0.5mm. This way, load fluctuations can be controlled within ±0.5%.

- Wear Resistance: High-pressure oil will inevitably have trace impurities. The valve core surface is nitrided (hardness reaches 800HV), so even after 8000 hours of operation, wear is minimal.

- Anti-Interference: Even if the oil source pressure occasionally fluctuates (e.g., ±0.1MPa), the output signal cannot change randomly, otherwise the regulating valve will "flicker".

These indicators are all to ensure that the unit is "stable, fast to regulate, and safe to run".

IV. What to look out for during daily inspections?

When we are doing on-site maintenance, we should focus on these points:

- Is there any sticking? If the valve core is stuck by impurities, it will cause the regulating valve to not move or act sluggishly. Abnormal running sounds will be heard, and the local pressure gauge may show large fluctuations.

- Leakage situation: Worn seals will leak oil. If oil stains are found, check and replace them promptly.

- Cleanliness: It is particularly sensitive to oil quality. Oil below NAS class 8 (with more impurities) will accelerate wear, so the oil purification system must be kept running well.

- Temperature difference effect: Drastic changes in oil temperature may cause the valve core to stick. During winter startup, be careful with warm-up to let the oil temperature rise slowly.

Remember, paying attention to these details can prevent many major failures.

V. Why is it so important?

For example, if the pressure regulator slide valve is slow to react, when the grid suddenly sheds its load, the steam turbine's speed will soar and may trigger the overspeed protection to shut down the unit. If the accuracy is not enough, the unit's load will fluctuate, which not only consumes more electricity but may also lead to penalties from the grid.

It can be said that it is the unsung hero behind a steam turbine that "runs stably, regulates accurately, and operates safely".

VI. Custom Fabrication per Drawings

We provide precision manufacturing of steam turbine pressure regulator slide valves strictly in accordance with your technical drawings. Our production fully complies with your specified requirements to ensure perfect alignment with your turbine's regulating system.

All custom slide valves undergo full inspection to ensure they integrate seamlessly with your turbine's actuator and signal system.

Keep Your Turbine's Regulation Precise—Choose Our Pressure Converter slide valve!

Our slide valves deliver fast response, high precision, and long wear life. Contact us now for a customized quote, performance testing consultation, or to share your drawings for a detailed manufacturing plan.