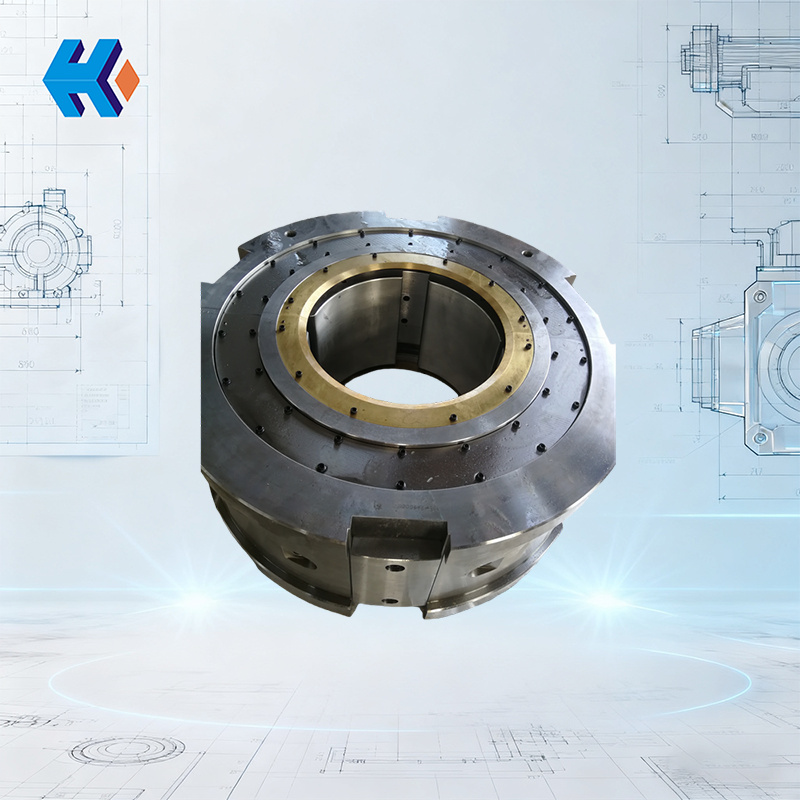

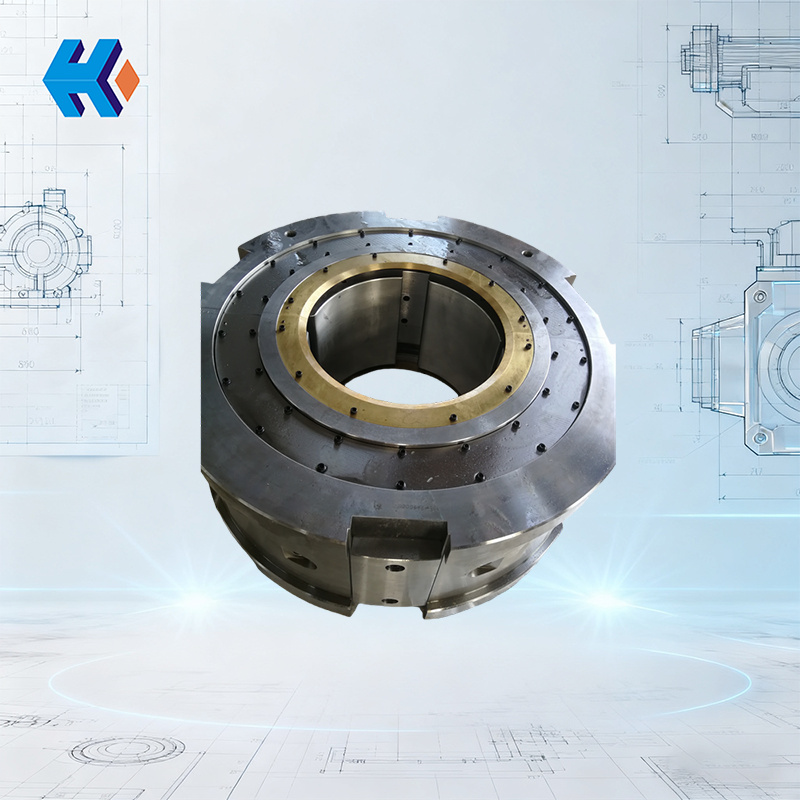

Steam Turbine Radial Bearing

Product Overview

A steam turbine radial bearing is a key component that ensures the steam turbine rotor remains stable, reduces vibration, and extends its service life during high-speed rotation. By providing the necessary support and lubrication, it prevents direct contact between the rotor and the cylinder, thereby avoiding wear and overheating. As a professional manufacturer of steam turbine spare parts and accessories, our radial bearings are made of high-quality materials and have excellent wear resistance, fatigue resistance, and reliability, suitable for long-term stable operation under various working conditions.

Application Scenarios

In a steam turbine, the radial bearing is mainly used to support the rotor journal, allowing it to run smoothly at high speeds and to withstand radial forces from the rotor. The working environment of radial bearings typically involves high temperatures, high pressures, and high-speed rotation, which places extremely high demands on material selection, machining accuracy, and durability. Our radial bearings are widely used in various thermal power, nuclear power, and industrial-driven steam turbine units to provide safe and reliable solutions for customers.

Main Materials

- Babbitt alloy: Has good conformability and embeddability, suitable for bearing surfaces.

- Bronze alloy: Good mechanical strength and self-lubricating properties, suitable for medium-load applications.

- Steel back + copper-based alloy: Combines high strength with excellent wear resistance, suitable for heavy-duty applications.

Product Types

- Elliptical bearing: The elliptical design helps to form a stable oil film and reduces vibration. It is suitable for high-speed, light-to-medium load applications.

- Tilting-pad bearing: The pads can be adjusted at a slight angle to automatically adapt to rotor eccentricity and optimize oil film distribution. It is suitable for high-speed, heavy-load applications.

- Multi-oil wedge bearing: Multiple oil wedge structures enhance oil film stability and reduce friction. It is suitable for medium-to-high speed applications.

- Cylindrical bearing: Simple structure and easy to maintain, suitable for low-speed, heavy-load applications.

Core Product Advantages

- Excellent Load-Bearing Capacity: The design complies with standards such as API 617 and GB/T 13663. It can withstand dynamic loads during startup, shutdown, and variable loads, ensuring smooth rotor operation.

- Superior Lubrication Performance: The tile surface is provided with oil grooves or guiding oil ramps, which facilitates the formation of a stable hydrodynamic oil film. This reduces the friction coefficient, lowers heat generation, and improves operating efficiency.

- Precision Machining, Accurate Dimensions: CNC grinders and profilers are used for inspection to ensure that key dimensions such as tile thickness, arc, and flatness have a tolerance of ≤0.02mm, ensuring that the assembly clearance meets design requirements.

- Strict Quality Control: Each batch of products undergoes:

- Ultrasonic flaw detection (UT) to check the bonding quality of the alloy layer.

- Hardness testing (HB, HRC).

- Full inspection of appearance and dimensions.

- Provision of material reports and factory inspection records.

- Customization of radial bearings of different specifications and materials based on drawings, physical samples, or unit models is supported.

Typical Application Parts

- Front and rear bearing housings of steam turbines.

- Support for high, intermediate, and low-pressure rotors of single-cylinder/multi-cylinder units.

- Radial bearings on the generator side or the main steam turbine side.

- Back-pressure, extraction-condensing, and condensing steam turbines.

Suggestions for Preventing Radial Bearing Failure

To extend the service life of radial bearings, it is recommended to pay attention to the following points:

- Regularly check the quality of the lubricating oil to prevent water or impurities from entering the oil.

- Monitor vibration data and promptly detect abnormal changes.

- Control the rate of temperature rise during startup and shutdown to avoid thermal shock.

- During major overhauls, check the amount of wear on the pads and whether the alloy layer has peeled off or cracked.

Custom Fabrication per Drawings

We provide precision manufacturing of steam turbine radial bearings strictly according to your technical drawings. Our production fully complies with your specified material requirements, key dimensional tolerances, and bearing type. We also adhere to conduct necessary inspections (UT, hardness testing) to ensure each bearing matches your turbine's rotor support needs, whether for maintenance or new unit assembly.

Ensure Rotor Stability—Choose Our Radial Bearings!

Our steam turbine radial bearings deliver reliable load support, stable lubrication, and long service life. Contact us now for a customized quote, free quality inspection report consultation, or technical support for bearing selection. We guarantee on-time delivery and after-sales maintenance guidance to keep your turbine running smoothly.