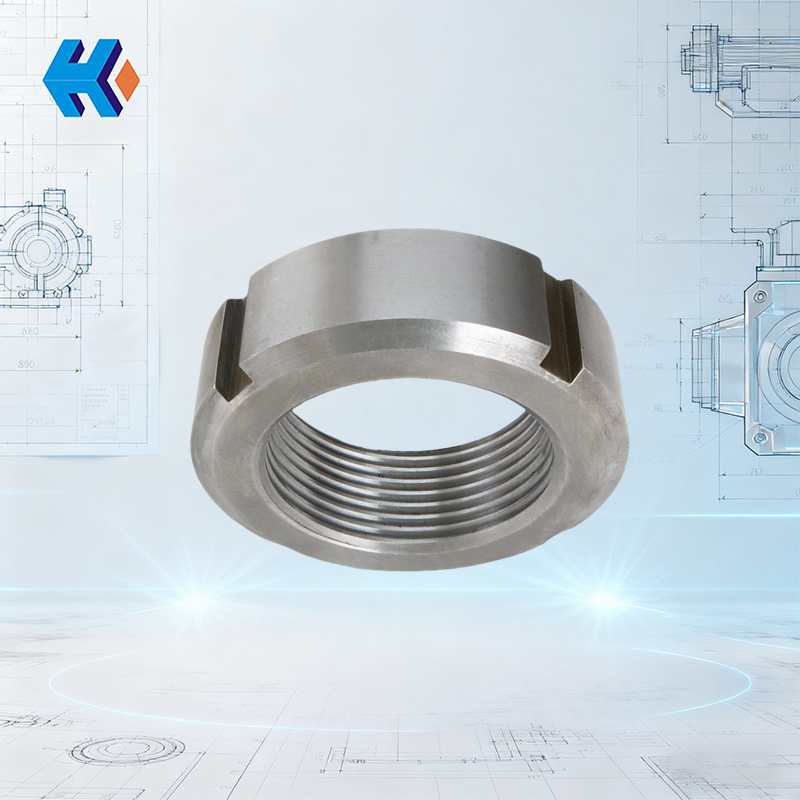

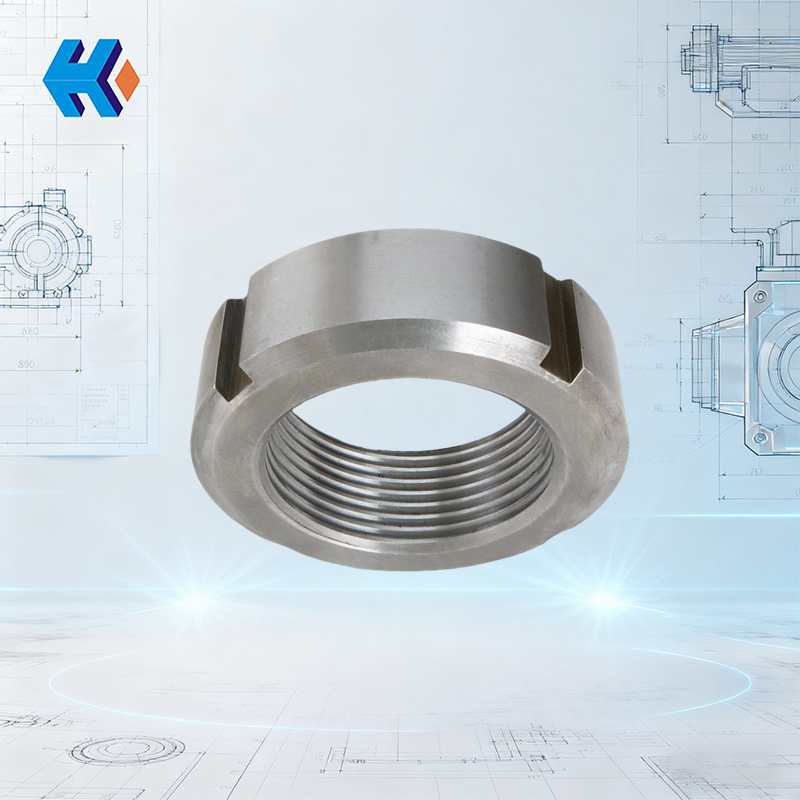

Customized Nuts for Steam Turbine HP and IP Cylinder

Steam turbine HP and IP cylinder nuts are critical fastening components that connect the HP and IP cylinder bodies, flanges, and related parts. They are directly related to the cylinder's sealing performance, structural stability, and the unit's operational safety. During steam turbine operation, the HP and IP cylinders are subjected to a long-term environment of high temperatures (300°C to 566°C) and high pressures (16MPa to 30MPa), and they withstand frequent temperature fluctuations and mechanical stress. This places extremely high demands on the nuts' strength, heat resistance, and sealing capabilities.

Our factory produces HP and IP cylinder nuts using high-quality alloy structural steel, such as 35CrMoA, 25Cr2MoVA, and 45Cr1MoV. These nuts are compatible with subcritical, supercritical, and ultra-supercritical steam turbines of different capacity levels, including 300MW, 600MW, and 1000MW. They are also compatible with major mainstream models on the market, ensuring long-term reliable fastening under extreme conditions.

Core Performance Features

- Customized Materials for Different Operating Conditions

- 35CrMoA: Suitable for IP cylinder flange connections where temperatures are ≤400°C. It has excellent comprehensive mechanical properties (tensile strength ≥900MPa, yield strength ≥750MPa), good hardenability, and stable welding performance. It can withstand medium-load fastening needs.

- 25Cr2MoVA: Suitable for HP cylinder parts where temperatures range from 400°C to 500°C. This is a chromium-molybdenum-vanadium series heat-resistant steel with outstanding oxidation resistance (no significant flaking of the oxide layer after long-term operation at 500°C). Its high-temperature yield strength is ≥440MPa, which can effectively resist thermal relaxation and prevent the decay of bolt pre-tightening force.

- 45Cr1MoV: Suitable for the high-temperature sections of ultra-supercritical units (temperatures from 500°C to 566°C). The added vanadium element strengthens grain boundary stability. Its long-term high-temperature strength (550°C/1000h) is ≥180MPa, and it has excellent creep resistance. It can maintain stable fastening force under long-term high-temperature and high-pressure conditions, preventing cylinder leakage.

- All materials undergo spectral analysis and metallographic inspection to ensure their chemical composition meets the GB/T 3077 standard, preventing material mixing or composition deviation.

- Precision Machining and Heat Treatment to Ensure Dimensional Accuracy and Mechanical Properties

- Machining Accuracy: The threads are formed by a rolling process. The thread profile is complete, and the surface roughness is Ra≤1.6μm. The fit clearance with the bolt is controlled between 0.02mm and 0.05mm, which prevents stress concentration due to poor fit. The parallelism of the nut end face is ≤0.01mm/100mm, ensuring uniform contact with the flange face and preventing local leakage.

- Heat Treatment Process: The heat treatment plan is customized according to the material properties. 35CrMoA uses "850°C oil quenching + 550°C tempering," 25Cr2MoVA uses "900°C oil quenching + 650°C tempering," and 45Cr1MoV uses "920°C oil quenching + 700°C tempering". This ensures the hardness reaches 240-280HB and that the internal structure is uniform (no overheating or overburning) with an impact toughness of αk≥35J/cm².

- Anti-Relaxation and Sealing Design for Dynamic Conditions

- Thermal Relaxation Resistance: Verified by a high-temperature relaxation test (simulating 500°C/1000 hours of operation), the pre-tightening force loss rate is ≤5%, which is far below the industry standard (≤10%). This can effectively prevent nut loosening caused by unit startup, shutdown, and load changes, ensuring long-term cylinder sealing.

- Anti-Seize Structure: The internal thread surface of the nut can be coated with a molybdenum disulfide layer (thickness of 5-10μm) as needed. This reduces the friction coefficient with the bolt (μ=0.1-0.15), making installation and disassembly easier, especially for maintenance at high temperatures.

- Full-Size Coverage for Diverse Connection Needs

- Nut specifications cover M36-M120 (thread diameter) and a thickness of 30mm-150mm. Dimensions can be customized based on the cylinder flange thickness and bolt specifications. It supports different head structures, such as hexagonal and round, to meet the needs of installation in narrow spaces or with special wrenches.

Application Scenarios and Compatible Models

• Typical application parts: connections for upper and lower cylinder flanges of HP and IP cylinders, connections between the cylinder body and the steam chamber, and fastening of inlet pipe flanges.

• Compatible unit examples:

- HP and IP cylinder flange nuts (25Cr2MoVA material) for a 600MW supercritical unit (N600-24.2/566/566).

- High-temperature section nuts (45Cr1MoV material) for a 1000MW ultra-supercritical unit (CC1000-25.0/600/600).

- IP cylinder nuts (35CrMoA material) for a 300MW subcritical unit (N300-16.7/538/538).

Custom Fabrication per Drawings

We provide precision manufacturing of steam turbine HP and IP cylinder nuts strictly in line with your technical drawings. Our production fully complies with your specified dimensional tolerances (thread accuracy, end face parallelism), material grades (35CrMoA/25Cr2MoVA/45Cr1MoV or other custom alloys), and surface treatments. We also adhere to industry standards to ensure each nut matches your turbine's unique connection requirements, whether for maintenance replacement or new unit assembly.

Secure Your Turbine's Fastening Reliability—Contact Us Today!

Our HP and IP cylinder nuts deliver stable performance under high temp/pressure, anti-relaxation, and precise sealing. Reach out now for a customized quote, or technical consultation. We guarantee on-time delivery, full quality inspection reports, and after-sales support to keep your turbine running safely and efficiently.