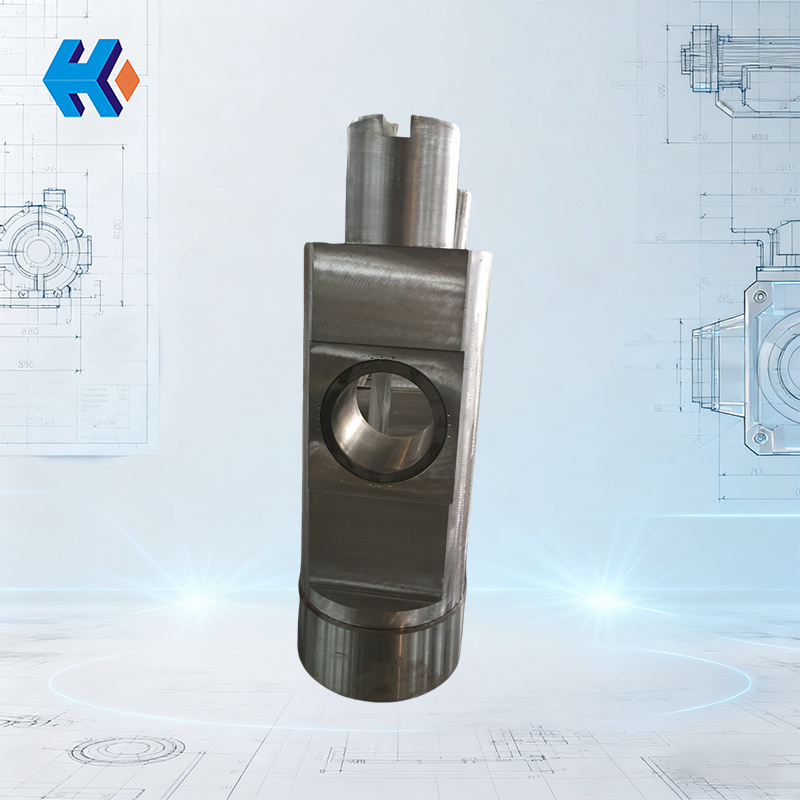

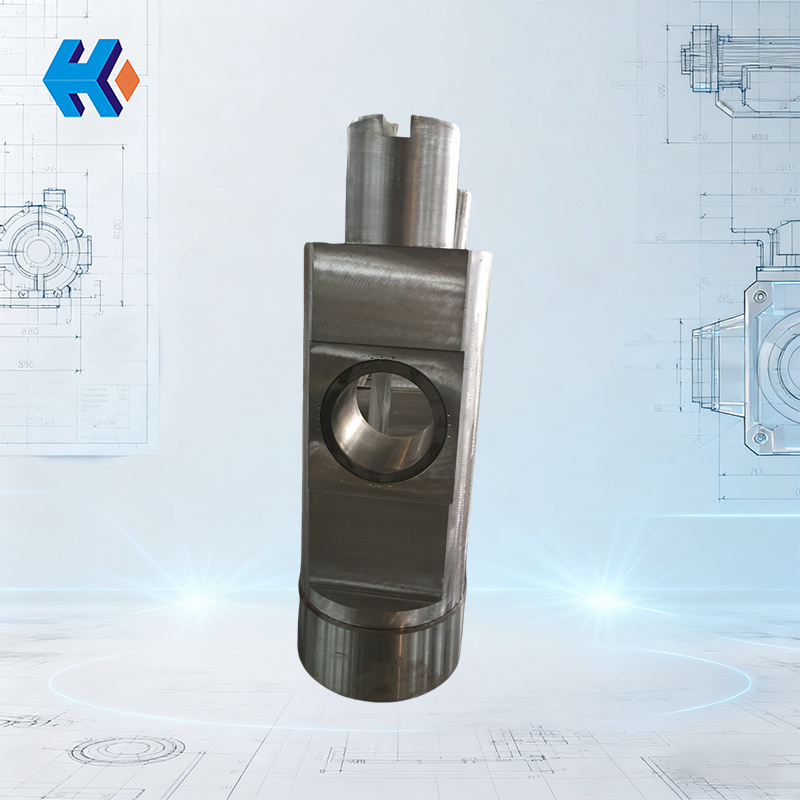

Crosshead for Steam Turbine High-Pressure Control Valve

The HP Control Valve Crosshead is an indispensable, high-precision transmission component within the turbine's sophisticated governing and speed control system. Functioning as the crucial link, it effectively connects the regulating mechanism (actuator) to the high-pressure control valve stem. Its primary role is to smoothly and efficiently transmit the precise actions of the governing device to the valve, enabling accurate and immediate control of high-pressure steam flow. This component's integrity and performance are paramount, directly influencing the turbine's operational stability, load control accuracy, and overall efficiency.

Core Function: Precise Force Transmission and Compensation

The central mission of the crosshead is the precise transmission and conversion of force and motion.

Force Transmission:

When the turbine requires a load adjustment or speed correction, the governing system initiates a command. The force generated by the actuator is channelled cleanly and directly through the crosshead to the valve stem. This action precisely translates into the vertical movement (up and down) of the valve core, thereby modulating the valve opening and regulating the steam flow rate to the turbine stages.

Built-in Compensation:

Beyond simple force transfer, the crosshead is engineered to actively compensate for minor installation misalignments and thermal deformation that occur during operation. This critical self-adjustment ensures a uniform and stable force transfer, effectively preventing issues like jamming, sticking, or uneven wear on the valve stem and sleeve surfaces.

Structural Design and Engineering Excellence

High-Strength, Optimized Structure

The component features a high-strength, one-piece forged structure, providing maximum rigidity and durability to withstand intense forces. The connection between the crosshead body and the internal guide sleeve is a precision sliding fit, engineered for minimal friction and maximum stability.

Enhanced Longevity and Low Friction

- Wear Reduction: The connection points between the crosshead, the regulating rod, and the valve stem are equipped with advanced, wear-resistant bushings. These bushings dramatically reduce the long-term deterioration caused by high-frequency, continuous movement.

- Integrated Lubrication: The internal sleeve incorporates a dedicated lubrication channel to deliver pressurized oil continuously. This effective lubrication system significantly lowers the friction coefficient of the sliding surfaces, drastically extending the service life of the critical components.

Dynamic Analysis Optimization

The crosshead's geometry and overall structure have been meticulously optimized through dynamic stress analysis. This ensures a rational force distribution throughout the component, allowing it to effectively withstand combined axial and radial forces during steam regulation and maintain flawless stability even during high-frequency governing operations.