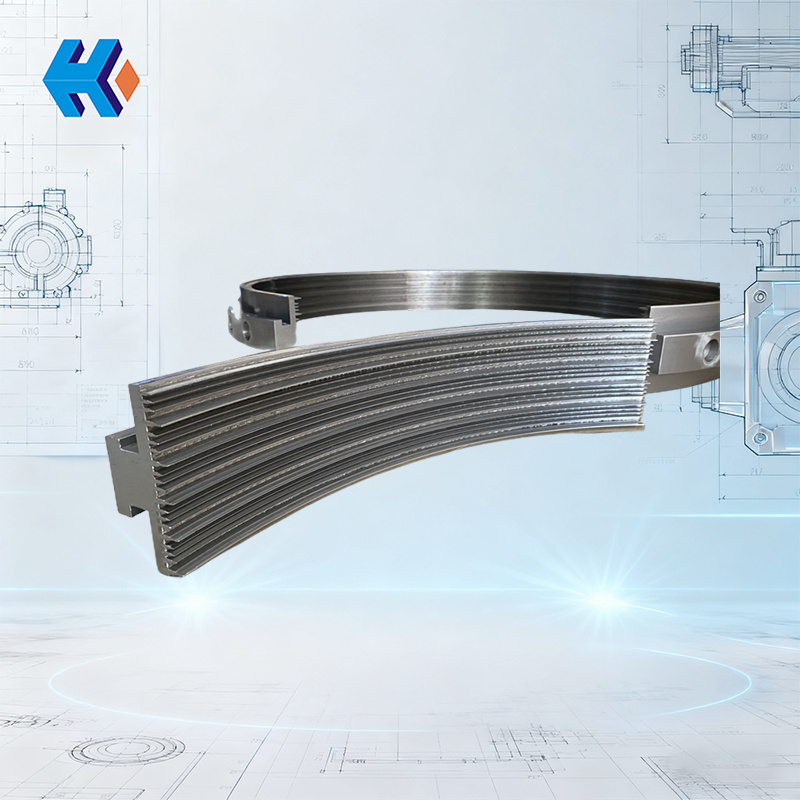

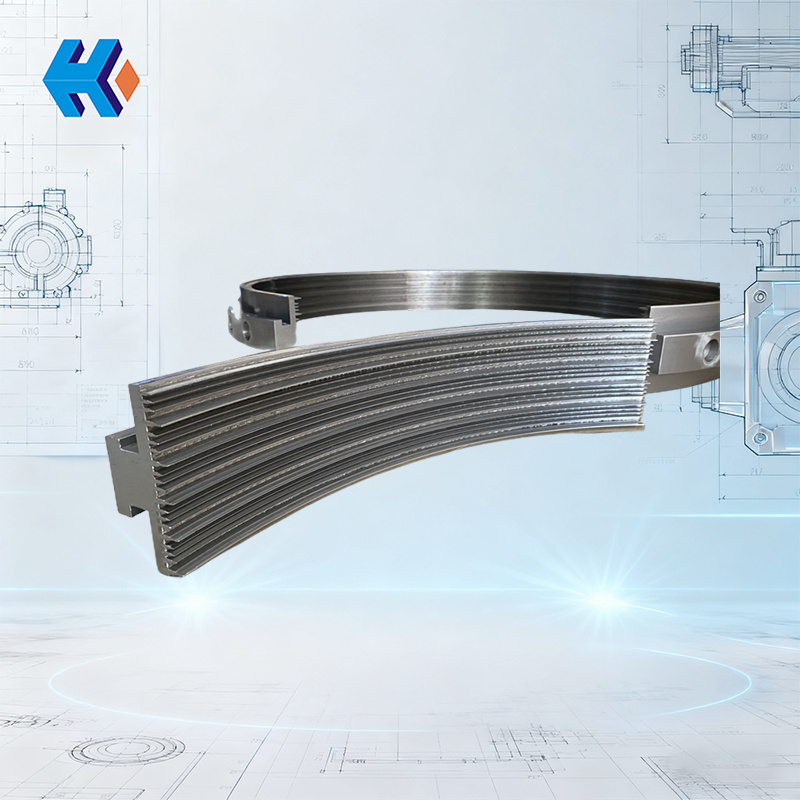

Steam Turbine Gland Seal Rings Machining Based on Drawings

Product Overview

Steam turbine gland seal rings are a critical sealing component of the steam turbine's flow path section. They are mainly installed in the gaps between the moving and stationary parts of the steam turbine, including the shaft-end gland seals, diaphragm seals, and blade-tip seals. Their core function is to reduce the leakage of high-temperature and high-pressure steam in the gaps between the moving and stationary parts, while also preventing air from leaking into the vacuum system. They directly affect the steam turbine's operating efficiency, energy consumption level, and safety and stability, making them an important spare part for ensuring the unit's economic and efficient operation.

Product Features

- High-Efficiency Sealing Design: Uses advanced structural designs such as multi-tooth, honeycomb, or labyrinth seals. Through the principle of multi-stage throttling and pressure reduction, they minimize steam leakage. The sealing efficiency is increased by 15-30% compared to traditional structures, significantly reducing the unit's steam consumption rate.

- Excellent Wear Resistance and Temperature Resistance: Based on the characteristics of different working areas, high-strength alloys, wear-resistant cast iron, or special composite materials are selected for manufacturing. They can work stably for a long time in temperature environments of 300-600°C and have good resistance to wear, corrosion, and thermal deformation.

- Precise Clearance Control: Adopts precision machining processes to ensure the best fit clearance between the seal rings and the rotor. While guaranteeing the sealing effect, it effectively avoids the risk of rubbing between moving and static parts, improving the unit's operational safety.

- Flexible Installation and Adjustment Performance: Designed with a reasonable adjustment structure and positioning method, making on-site installation and debugging easy. The clearance can be adjusted as needed according to the unit's operating status to adapt to sealing requirements under different working conditions.

Technical Parameters

- Compatible Models: Steam turbines of various capacity levels, from 100MW to 1000MW.

- Material Selection:

- High-Pressure Areas: Martensitic stainless steel such as 1Cr13, 2Cr13.

- Medium- and Low-Pressure Areas: Gray cast iron, ductile iron, tin bronze.

- Special Conditions: High-temperature alloys, honeycomb structure materials.

- Structural Forms: Labyrinth, honeycomb, contact, etc.

- Working Temperature: ≤600°C.

Product Advantages

- Improves Unit Efficiency: Reduces steam leakage loss, which can increase steam turbine efficiency by 1-3% and significantly reduce power generation coal consumption.

- Extends Overhaul Cycle: Uses wear-resistant materials and an optimized structure, extending the service life to 4-6 years and reducing the number of shutdown overhauls.

- Enhances Operational Safety: Has good yielding and impact resistance, effectively preventing rubbing accidents between moving and static parts caused by vibration or thermal deformation.

Application Scenarios

Widely used in thermal power plants, nuclear power plants, biomass power plants, waste-to-energy power plants, and other steam turbines in the high-, medium-, and low-pressure cylinders, shaft ends, and diaphragm parts. It is a core replacement part for steam turbine flow path section modification, energy-saving upgrades, and routine maintenance.

Custom Fabrication per Drawings

We provide precision manufacturing of steam turbine gland seal rings strictly according to your technical drawings. Our production fully complies with your specified requirements: including material selection (1Cr13, gray cast iron, high-temperature alloys, etc.), structural forms (labyrinth, honeycomb, contact), precise clearance control, and working temperature adaptation. We also conduct dimensional accuracy inspections and sealing performance tests to ensure each seal ring meets your turbine’s flow path sealing needs, whether for energy-saving upgrades, maintenance replacement, or new unit assembly.

Cut Steam Leakage, Boost Turbine Efficiency—Choose Our Gland Seal Rings!

Our gland seal rings deliver high sealing efficiency, long service life, and reliable safety performance. Contact us now for a customized quote, technical consultation. We guarantee on-time delivery and after-sales installation guidance to help your turbine operate more economically and stably.