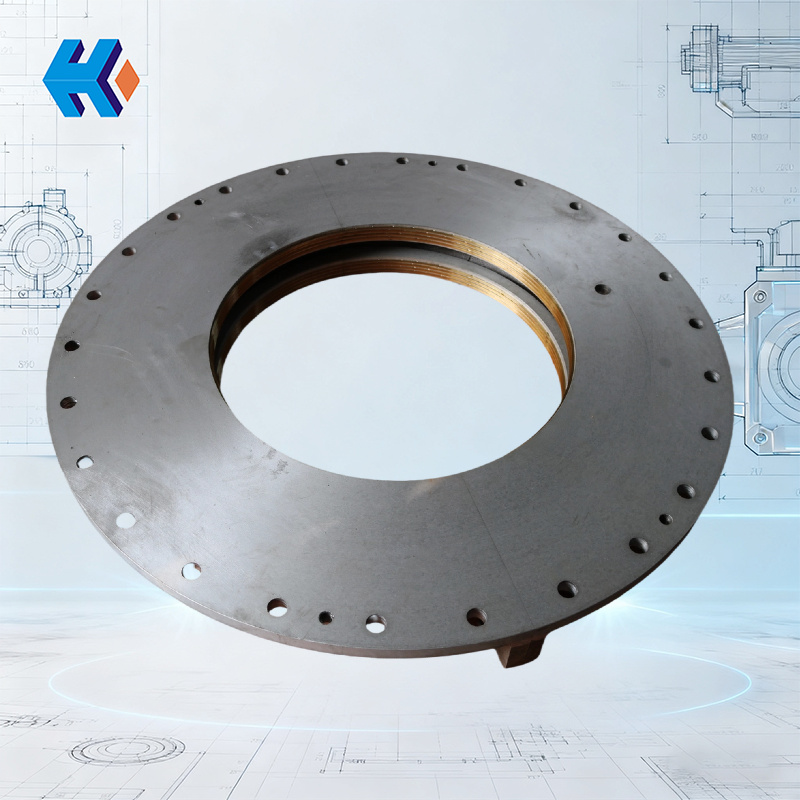

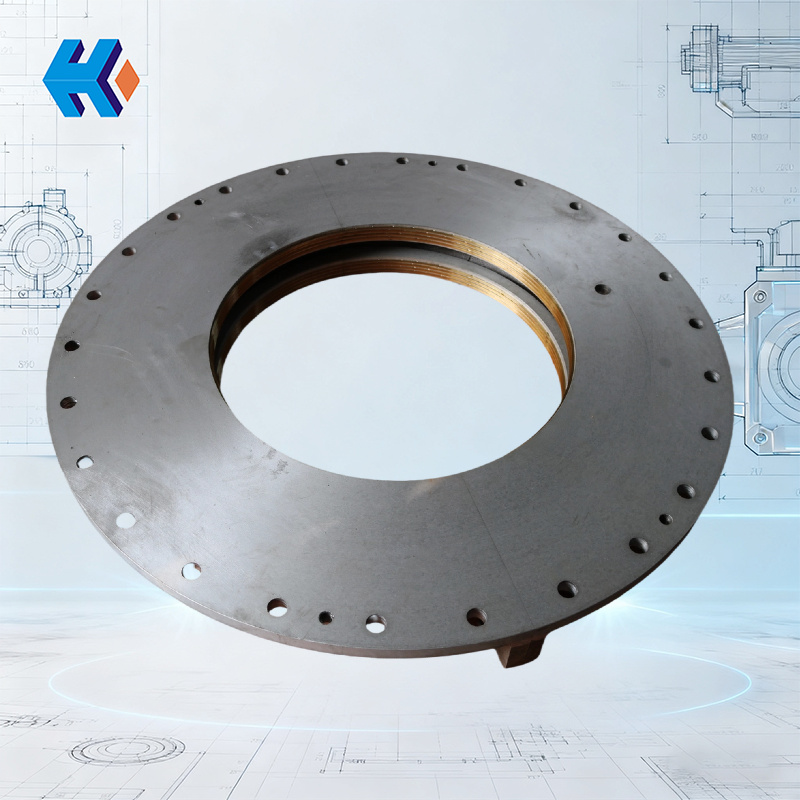

Generator Oil Baffle Ring

The oil baffle is a simple yet vital component in generator sets, serving as the primary barrier for retaining lubrication and blocking external contaminants to ensure machinery longevity and environmental compliance.

1. Functions of Oil Baffles

- Preventing Lubricating Oil Leaks: The main function is to prevent oil from escaping the equipment, particularly at bearing locations. This minimizes oil waste, avoids environmental pollution, and maintains critical internal lubrication.

- Preventing External Contaminant Ingress: The baffle acts as a seal against external elements like dust, moisture, and dirt, protecting internal precision components from corrosion and abrasive wear.

- Maintaining Internal Lubrication and Cooling: By ensuring oil retention, the baffle sustains proper oil circulation within the equipment, preserving its lubrication and cooling effects and extending the component's service life.

- Improving Equipment Reliability and Safety: By effectively preventing oil leaks and contamination, oil baffles significantly boost the equipment's operational reliability and safety, reducing the likelihood of unexpected failures.

2. Application Locations of Oil Baffles

Oil baffles are strategically deployed across critical lubrication points in various generator types:

- Outside Bearing Housings: They are installed outside the bearing housings at both ends of the generator to prevent lubrication oil from entering the generator's core area and simultaneously preventing external leaks.

- Main Shaft Seal Oil Baffle (Wind Turbines): Often uses a floating seal ring with elasticity. This specialized design adapts to shaft vibrations, preventing increased sealing gaps over time and effectively stopping grease leaks.

- Pedestal Bearings (Turbine Generator Sets): Inner and outer oil baffle plates work with the shaft journal clearance to prevent oil splashing and leakage from the pedestal bearings.

- Oil Grooves (Hydroelectric Generator Sets): Oil baffles, typically employing a gas-sealed device, are crucial in the oil grooves to suppress the escape of oil mist into the surrounding air.

- Exciter Oil Baffle: Used on turbine generator exciters to prevent lubricating oil seepage. Modification with a gas-sealed oil baffle is a common solution for seepage issues often caused by insufficient lubricating oil exhaust fan power.

3. Conditions for Replacing Oil Baffles

Prompt replacement of oil baffles is essential when any of the following conditions are observed:

-

Seal Failure:

- Visible Lubricating Oil Leakage: Leakage indicates sealing deterioration, requiring immediate replacement to prevent oil waste and contamination of other generator parts.

- Ingress of External Contaminants: If dust or moisture is found in the protected area, it signals a seal failure, which can quickly lead to corrosion and wear of internal components.

-

Oil Baffle Wear:

- Mechanical Wear: Wear exceeding the design tolerance from long-term friction means the baffle can no longer effectively block oil and contaminants.

- Weakened Elasticity: For elastic designs (like floating rings), a decrease in elasticity prevents the baffle from adapting to shaft vibrations and displacements, significantly reducing sealing effectiveness.

-

Oil Baffle Aging:

- Material Aging: High temperatures, chemical exposure, or long-term use can cause the material to crack, harden, or become brittle, leading to a decline in sealing performance.

- Performance Decline: Even without visible damage, performance degrades over time. Regular performance checks (sealing effectiveness, elasticity) are vital for timely detection and replacement.

🔧 Custom Sealing Solutions: Upgrade Your Oil Baffles for Zero Leakage

We provide custom-engineered oil baffles and seal rings utilizing advanced polymers, specialized elastic alloys, and high-precision machining. Our bespoke designs ensure optimal clearance fit, superior vibration tolerance, and chemical resistance, eliminating seepage and contamination issues permanently.

Contact us to request a quote for custom oil baffles. Ensure perfect internal lubrication and external cleanliness!

GET A FREE QUOTE AND CONSULTATION