Thrust Bearing Pads for Generator Units

A thrust bearing employs a self-aligning design that automatically adjusts the load on the thrust pads, ensuring stable operation. This crucial design allows the thrust pads to adapt instantly to the rotor's axial displacement, significantly reducing wear and damage caused by uneven loads. Installed in the front bearing seat, the thrust bearing axially positions the shaft system. When stationary components expand or contract due to temperature changes, the entire shaft system remains stable and aligned due to the bearing's ability to adjust its positioning points.

1. Functions of Thrust Pads

Thrust pads, also known as thrust shoes, are essential for managing axial forces and maintaining precise clearances:

- Balancing Axial Thrust: The primary role is to balance the rotor's axial thrust and establish the rotor's expansion dead point, ensuring the axial clearance between moving and stationary parts stays within the design limits.

- Determining Rotor Position: During normal operation, the working pads bear the load, preventing the rotor from displacing toward the generator side.

- Protecting the Rotor: During load reduction or shedding, the non-working pads absorb the force, preventing the rotor from moving towards the head end due to inertia.

- Lubrication and Cooling: The friction-generated heat is absorbed by the lubricating oil circulating over the pads and is then cooled by an oil cooler. This system reduces friction, preventing overheating and extending the service life of the pads.

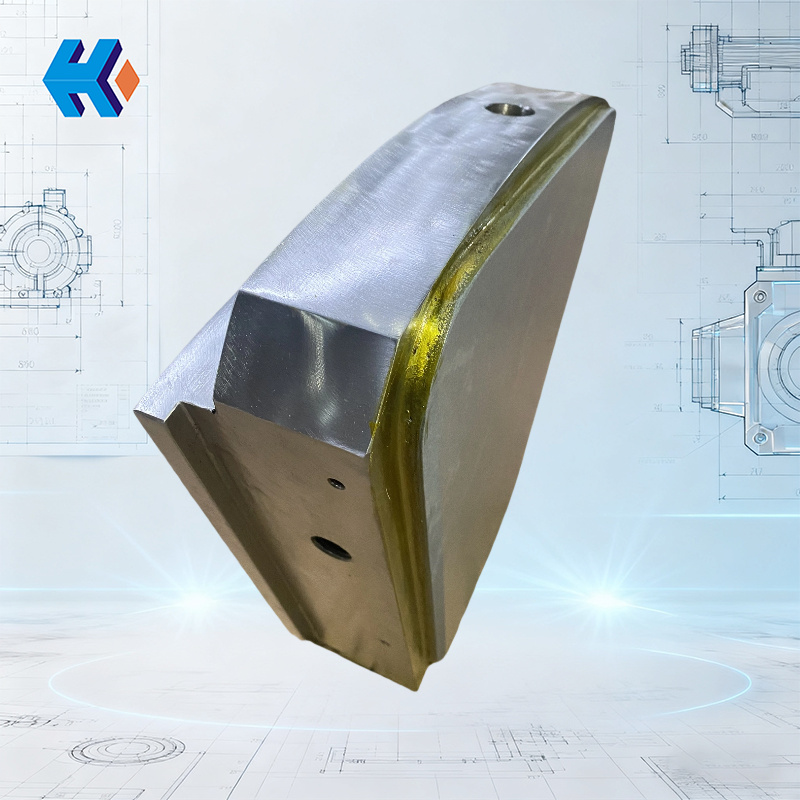

2. Materials and Structure of Thrust Pads

Materials:

- Steel Billet + Babbitt Alloy: Babbitt alloy is cast onto a steel tile body to create a thin, uniform lining. This material offers excellent anti-friction properties and load capacity, maintaining stable performance under high loads.

- Tin Bronze: Suited for higher temperature environments, offering increased corrosion and wear resistance compared to standard materials.

- Steel Billet + Fluoroplastic (PTFE/Teflon): Offers a low coefficient of friction and high-temperature stability. This combination is less prone to scorching in case of temporary oil loss, making it an ideal choice for reliability.

Structure:

Thrust pads typically utilize a sectorial block type structure. They are supported by a bearing seat and feature a groove containing turbine oil for lubrication and cooling. This design ensures the load is distributed evenly, minimizing localized wear and maximizing stability.

3. Installation and Maintenance of Thrust Pads

Installation Precautions:

- Clearance Adjustment: The clearance between the thrust pads and the rotating shaft must be strictly adjusted according to design specifications. Correct clearance is vital for reducing wear and ensuring operational efficiency.

- Cleaning and Inspection: Pads must be thoroughly cleaned and inspected for any damage or wear before installation. Even minor imperfections can severely affect performance.

- Secure Fastening: The pads must be securely fastened to the generator end cover to prevent operational displacement, which could lead to severe vibration and component failure.

Maintenance Recommendations:

- Regular Inspection: Periodically inspect the wear condition of the thrust pads. Timely repair or replacement effectively extends the service life and reduces the risk of equipment failure.

- Lubrication System Check: Ensure the lubrication and cooling system is operating correctly to prevent dry friction due to insufficient oil. A robust lubrication system is key to reducing friction and heat buildup.

🔧 Precision Engineering: Custom Thrust Pads for Peak Performance

We specialize in custom-engineered thrust pads utilizing advanced materials like proprietary Babbitt alloys or PTFE composites, precisely designed to your unit's unique specifications. We ensure perfect clearance geometry and superior hydrodynamic stability to handle the most demanding axial thrust loads.

Contact us to connect with our bearing experts for a technical assessment and a quote on custom thrust pads. Ensure precise axial positioning and extend your rotor's life!

GET A FREE QUOTE AND CONSULTATION