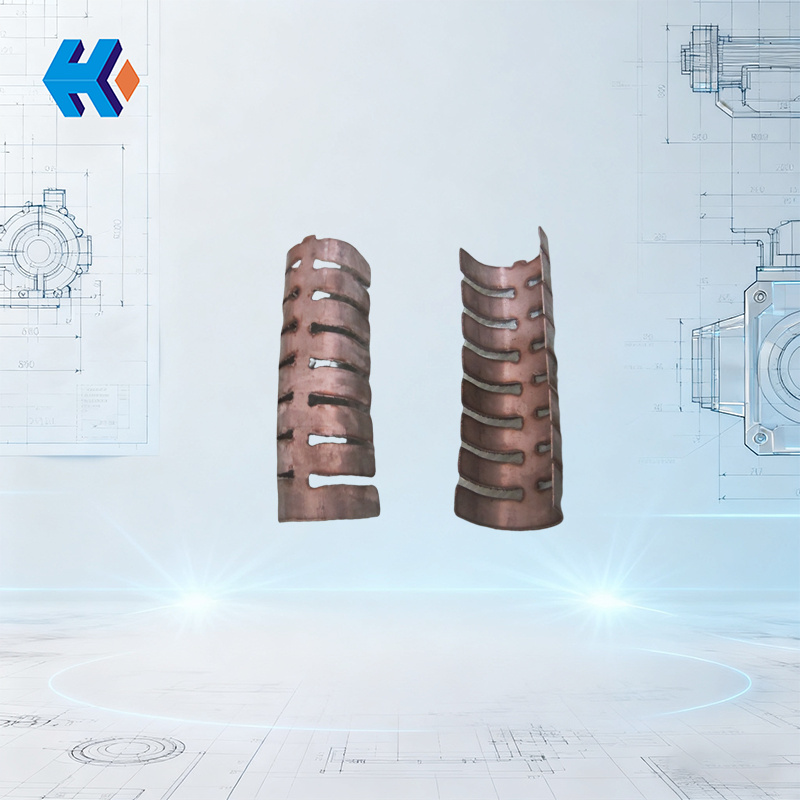

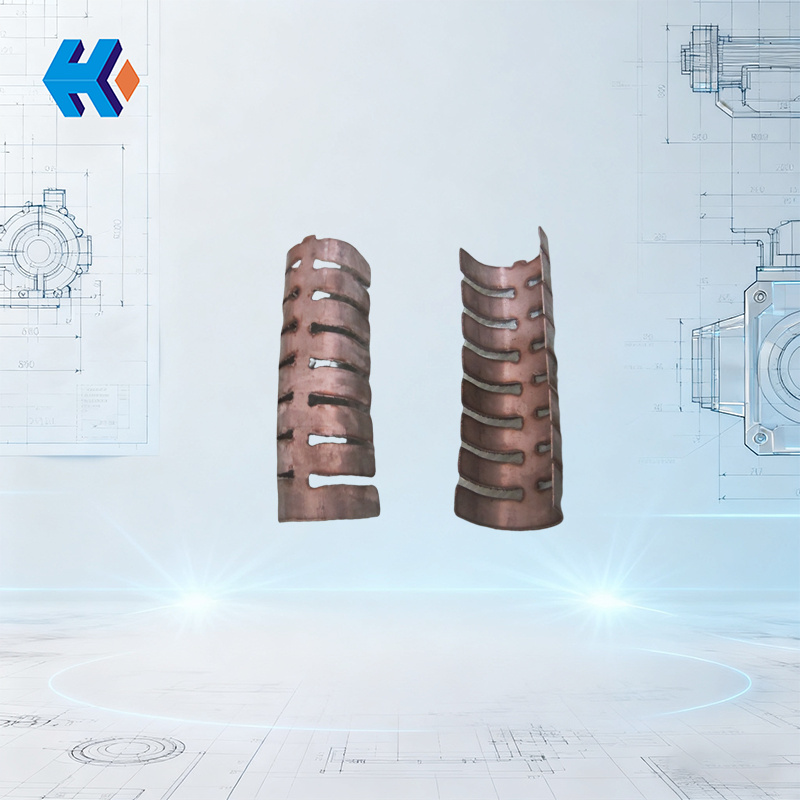

Comb-type Anti-wear Shield for Boiler Pipes

A comb-type anti-wear shield is an anti-wear protection device commonly used on boiler heating surfaces (especially water-cooled walls, superheaters, reheaters, and other pipes). It is mainly used to mitigate the erosion and wear of tubes by high-velocity flue gas carrying fly ash particles, extending the service life of the heating surface tubes and ensuring the safe and stable operation of the boiler. When the boiler is operating, high-temperature flue gas carries a large amount of fly ash (such as unburned pulverized coal particles in pulverized coal boilers, or bed material particles in circulating fluidized bed boilers) flowing at high velocity over the heating surface tubes.

The comb-type anti-wear shield works in the following ways:

- Blocking and Guiding: The teeth directly block the direct impact of fly ash particles on the tubes, while also guiding the flow of flue gas, reducing local velocity, and lessening the force of particle erosion on the tubes.

- Dispersing Wear: Fly ash particles first contact the teeth of the anti-wear shield. The wear is mainly concentrated on the shield, which indirectly protects the heating surface tubes underneath, preventing accidents like tube bursts caused by tubes becoming too thin due to localized wear.

Structural Features of the Comb-type Anti-wear Shield:

- "Comb-like" shape: It consists of multiple parallel metal plates (teeth) connected to a base, with the overall shape resembling a comb.

- Gaps between teeth: A certain gap is left between the teeth to facilitate flue gas flow while effectively blocking fly ash from directly eroding the tube surface.

- Material: It is mostly made of high-temperature and wear-resistant alloy steel (such as Cr25Ni20) to adapt to the harsh environment inside the boiler with high temperatures (usually above 400°C) and high dust content.

Comb-type anti-wear shields are mainly used in areas of the boiler furnace's water-cooled walls, platen superheaters, and convection tube bundles that are susceptible to fly ash wear, and they are widely used in circulating fluidized bed boilers (due to their high dust concentration and strong particle erosion). The anti-wear effect of comb-type anti-wear shields is more significant in areas with high flue gas velocity and coarser fly ash particles. During installation, the comb-type anti-wear shield is usually welded to the windward side or susceptible area of the heating surface tubes, ensuring it fits tightly against the tube to prevent loosening, which could worsen wear due to increased flue gas vortices. During operation, the wear of the anti-wear shield should be checked regularly. If the teeth show severe deformation, wear, or detachment, they should be replaced promptly to ensure the anti-wear effect.

With its simple structure, low cost, and reliable anti-wear effect, the comb-type anti-wear shield has become an important method for protecting boiler heating surfaces, and it is of great significance for improving the safety and economy of boiler operation.