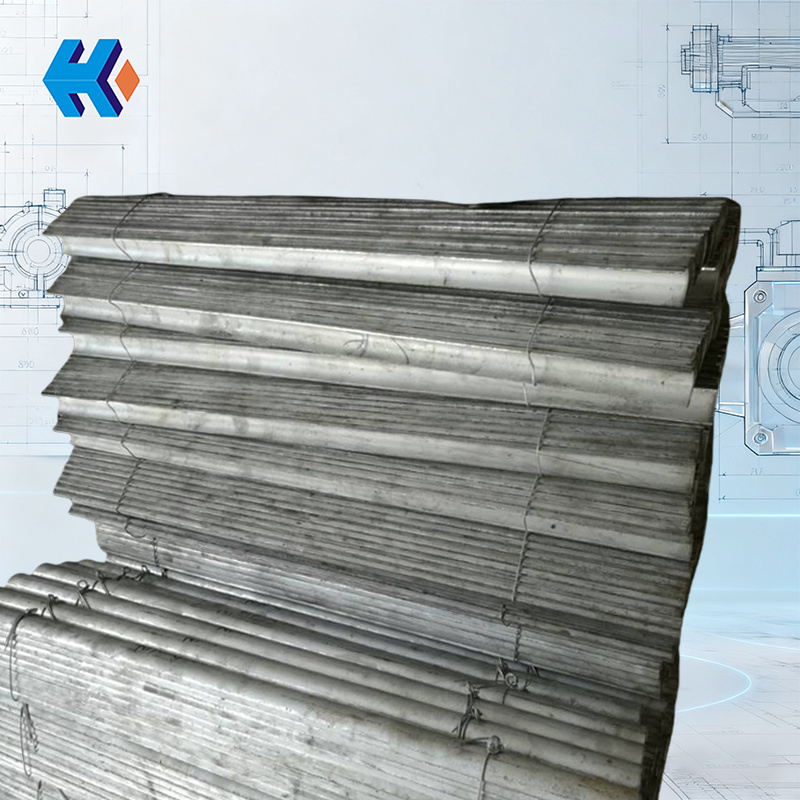

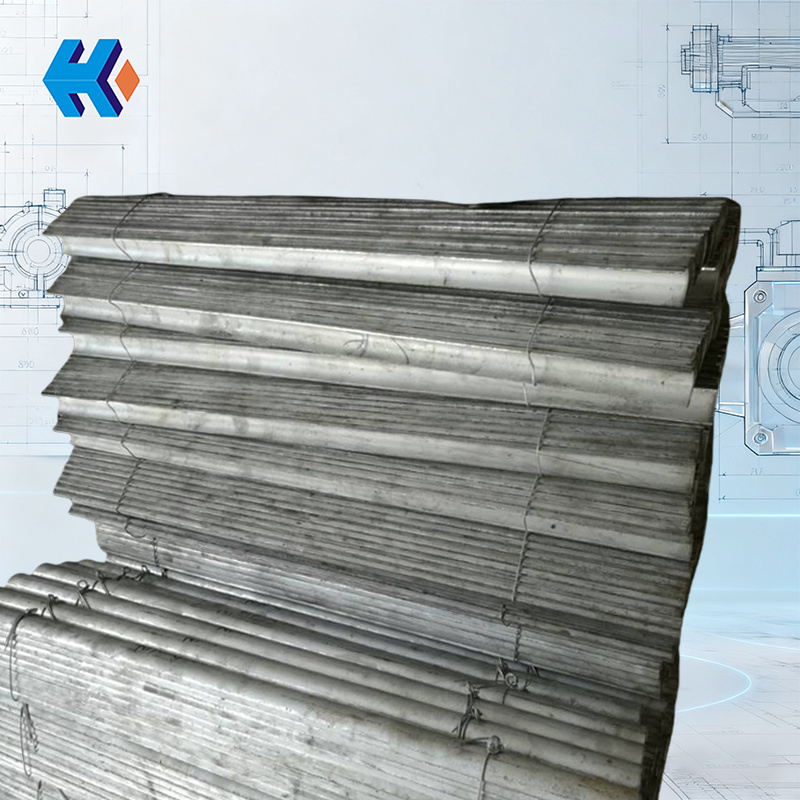

Pipe Shield Anti-wear Cover for Superheater of Power Station Boiler

The anti-wear cover is a key protective component in high-temperature, high-velocity, dust-laden fluid equipment like boilers and pipelines. It protects the heating surfaces or pipe walls from particle erosion and wear. It is widely used on heating surface tube bundles of superheaters, reheaters, and economizers in power plant boilers, as well as on wear-prone sections of material conveying pipelines.

Structural Design of Anti-wear Cover

The design is centered on “close-fit protection” and has the following features:

- Shape adaptability: It is mostly an arc-shaped or flat metal tile, with a curvature that matches the outer diameter of the protected pipe (e.g., designed for common heating surface pipes like φ38mm and φ51mm). It can tightly fit on the outer wall of the pipe to form a comprehensive protective layer.

- Dimensions: Length is typically 100-500mm (can be customized based on the length of the wear area), width is slightly larger than half of the pipe’s circumference (for easy wrapping and fixing), and thickness is generally 3-10mm (adjusted based on wear intensity; the more severe the wear, the greater the thickness).

- Connection structure: The edges of some anti-wear cover plates have positioning holes or buckles, and they are installed by spot welding, clamping, or welding to the pipe to ensure they do not loosen or shift under high-velocity airflow or material impact.

Materials of Anti-wear Cover Plate

Materials must meet requirements for high-temperature resistance, wear resistance, and matching thermal expansion coefficient with the protected component.

- Heat-resistant steel: Such as 12Cr1MoV, 15CrMo, etc., suitable for medium-temperature areas of 300-550°C (e.g., economizers, low-temperature superheaters), with good oxidation resistance and moderate wear resistance.

- High-chromium cast iron: Such as Cr20, Cr26, etc., with a high chromium content (15%-30%), which forms a hard carbide layer. Its wear resistance is 3-5 times that of ordinary heat-resistant steel. It is suitable for areas subjected to high-velocity, dust-laden flue gas erosion (e.g., furnace outlet, superheater tube bundles). However, it is more brittle and should be protected from violent impacts.

- Bi-metal composite material: The base layer is heat-resistant steel (ensuring strength and toughness), while the surface is hard-facing welded with a high-hardness alloy (such as tungsten carbide, nickel-based alloy). This material combines high-temperature and wear resistance, making it suitable for harsh environments with both wear and high temperatures (e.g., heating surfaces of circulating fluidized bed boilers).