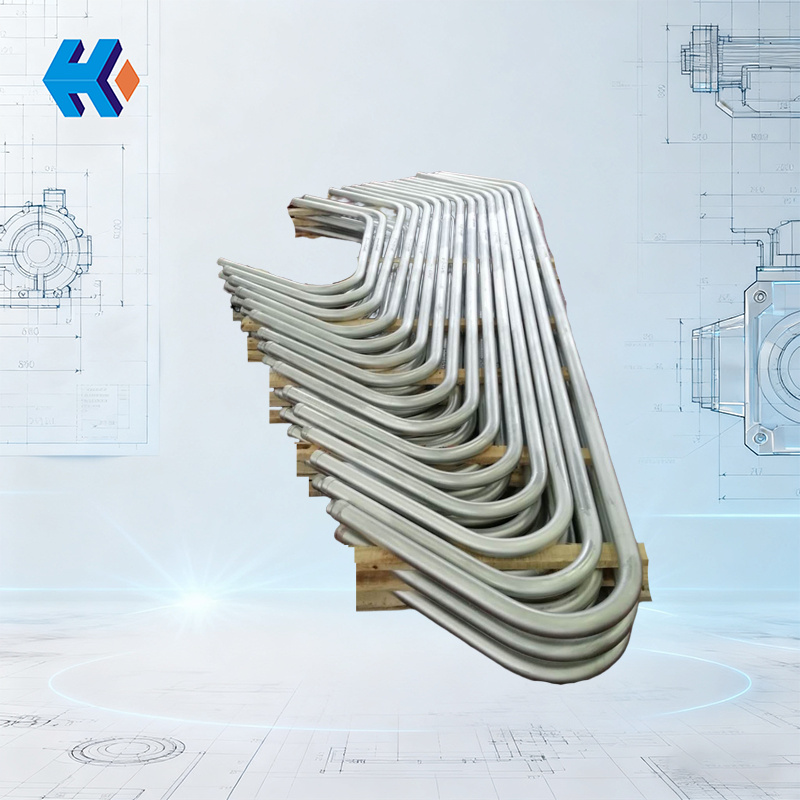

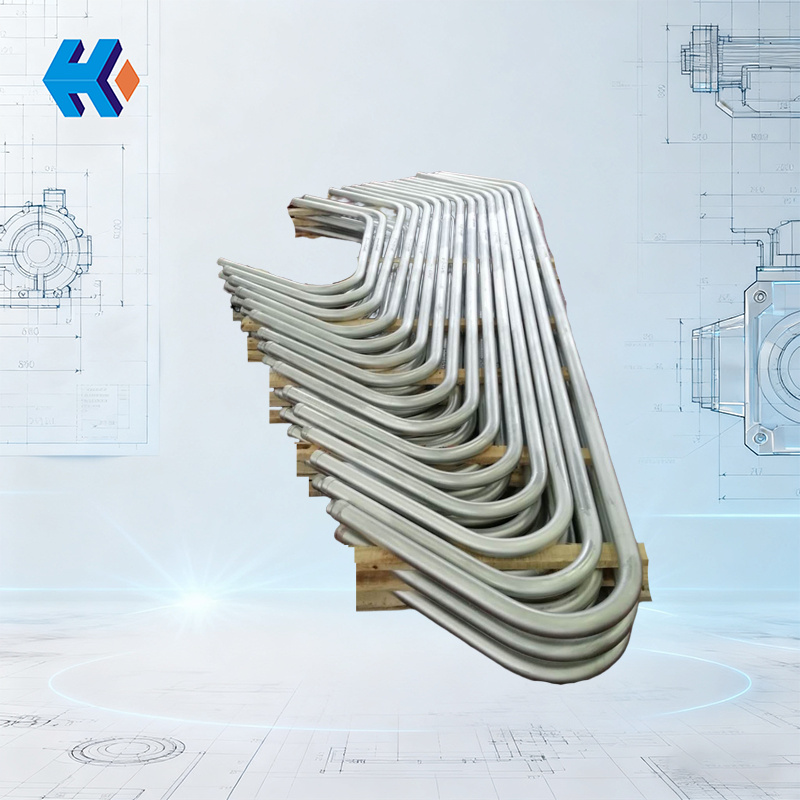

Offset Tubes for Boiler Burner

The burner offset tube is a key component in the boiler combustion system, mainly used for structural clearance and pipeline layout during burner installation. It ensures the spatial coordination between the burner and other boiler components to avoid mutual interference. Its main function is to prevent direct erosion of the water-cooled wall tubes by high-temperature flue gas and particles from the burner, thereby reducing wear. During the combustion process in the boiler furnace, the furnace is divided into a dense phase zone, a transition zone, and a dilute phase zone. The transition zone is where the water-cooled wall is most susceptible to wear, and the offset tube structure can effectively protect this area. The design of the offset tube can optimize the burner's combustion process, ensuring flame stability and combustion efficiency. By reasonably designing the shape and position of the offset tube, it can prevent the flame from directly impacting the water-cooled wall, reducing localized overheating.

Design Principles of Burner Offset Tubes

1. Structural Design:

- The offset tube is usually designed as a pipe with a certain bending angle to guide the high-temperature flue gas and flame from the burner.

- The shape and size of the offset tube are optimized based on the specific burner model and combustion characteristics to ensure the best combustion effect and anti-wear performance.

2. Material Selection:

- Offset tubes are usually made of high-temperature and corrosion-resistant materials, such as alloy steel or stainless steel.

- Material selection must consider the high temperature and corrosiveness of the burner's working environment to ensure the long-term stable operation of the offset tube.

3. Installation and Fit:

- The offset tube needs to fit tightly with the burner, water-cooled wall tubes, and other components to ensure overall performance after installation.

- During installation, factors such as the flame direction of the burner and the adjustment range of the burner must be considered to ensure the offset tube effectively protects the water-cooled wall tubes.

Burner offset tubes are widely used in boiler systems of thermal power plants, especially in the burner area. They are also suitable for various types of burners, including swirl burners and direct-flow burners. The wear of the offset tube should be regularly checked, and severely worn parts should be replaced promptly. During boiler shutdown, the offset tube should be cleaned and inspected to ensure its surface is free of ash and corrosion.

Through reasonable design and installation of burner offset tubes, the boiler's water-cooled wall tubes can be effectively protected, the combustion process can be optimized, and the safety and operational efficiency of the boiler can be improved.