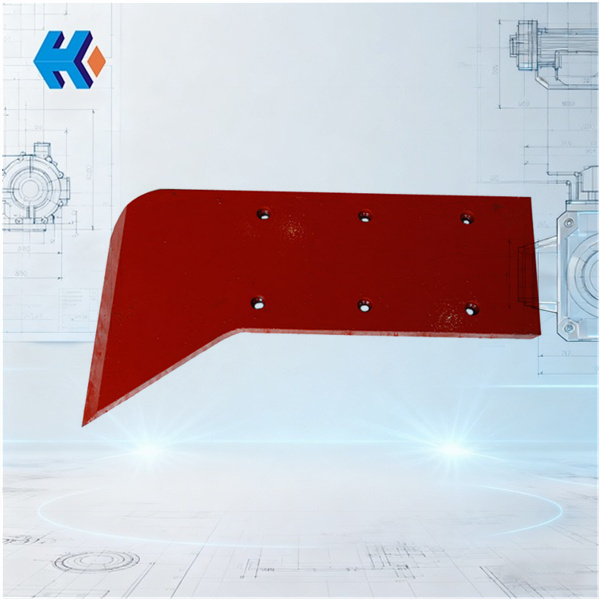

Protection and Performance of 20MG40.11.09.71 Coil Pulverizer Anti-Wear Plate

Protection and Performance of 20MG40.11.09.71 Coil Pulverizer Anti-Wear Plate

Description

The pulverizer anti-wear plate 20MG40.11.09.71 is installed within the coal pulverizer (also known as a coal mill). Looking at the overall structure of the pulverizer, the lower part of the casing is securely welded to the base, while the upper part is tightly connected to the classifier via bolts. The casing serves as the critical outer shell structure, not only protecting internal components but also defining key working areas. Specifically, the lower casing, along with the base top plate, transmission disc, and rotating nozzle ring, forms the primary air chamber. Within this operational environment, pulverized coal, driven by high-velocity airflow, severely scours the inner wall of the casing. It is here that the anti-wear plate 20MG40.11.09.71 takes on the crucial responsibility of withstanding this intense erosion.

The working principle of this anti-wear plate is based on its specialized material and structural design. The plate consists of two parts: a low-carbon steel substrate and an alloy wear-resistant layer, During operation, the low-carbon steel substrate provides excellent toughness, ductility, and resistance to external forces, ensuring the anti-wear plate does not easily deform or fracture when subjected to impact and vibration.

In terms of structural design, the connection method between the pulverizer anti-wear plate 20MG40.11.09.71 and the casing is meticulously engineered to maintain stability even in prolonged, harsh working conditions. Installation typically combines welding, bolt connections, or embedding to ensure the plate adheres tightly to the inner surface of the casing. This prevents gaps or looseness, thereby stopping coal dust from entering crevices and causing further erosion to the casing wall.

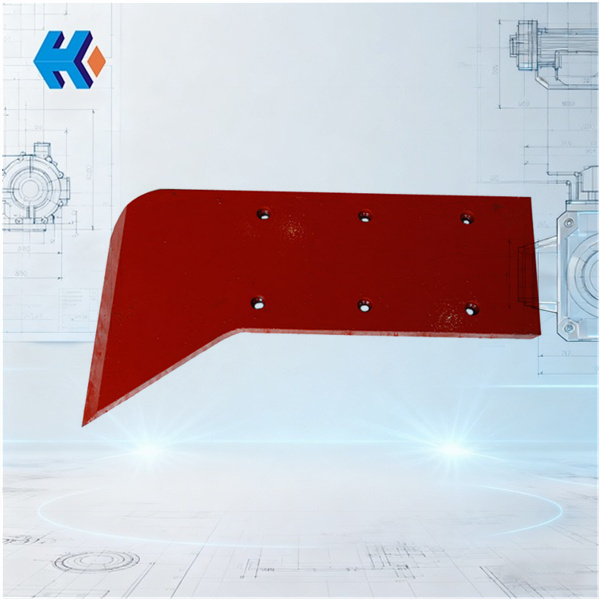

Dual-Layer Material & High-Temperature Durability

The operating environment of a coal pulverizer is complex and dynamic, involving not just coal dust abrasion but also high temperatures, high pressure, and potentially corrosive gases. In high-temperature conditions, typical metal materials can soften and deform, leading to a reduction in wear resistance. However, the alloy carbides used in the anti-wear plate 20MG40.11.09.71 exhibit strong thermal stability. They can maintain high hardness in environments up to $500^{\circ}C$ and possess good anti-oxidation properties, allowing the plate to effectively perform its wear-prevention role even under high-temperature operation. Furthermore, the material of the anti-wear plate offers a degree of corrosion resistance against potential corrosive gases, further safeguarding the plate's service life.

Maintenance and Replacement of Anti-Wear Components

Regular inspection and maintenance of the anti-wear plate 20MG40.11.09.71 is a vital part of pulverizer routine maintenance. Maintenance personnel must periodically enter the pulverizer through the casing's manhole door to check the wear condition of the plates. As different areas inside the pulverizer are subjected to varying degrees of coal dust erosion, the wear condition of the anti-wear plates will also differ. Areas showing severe wear must be repaired or replaced promptly. For minor wear, a resurfacing method like hardfacing welding can be used to deposit a new layer of wear-resistant material, restoring the plate's original thickness and durability. If the wear exceeds the specified limit, a complete replacement with a new anti-wear plate 20MG40.11.09.71 is necessary to ensure the continuous and effective wear protection of the coal pulverizer.

HKZX-2025-10-23.