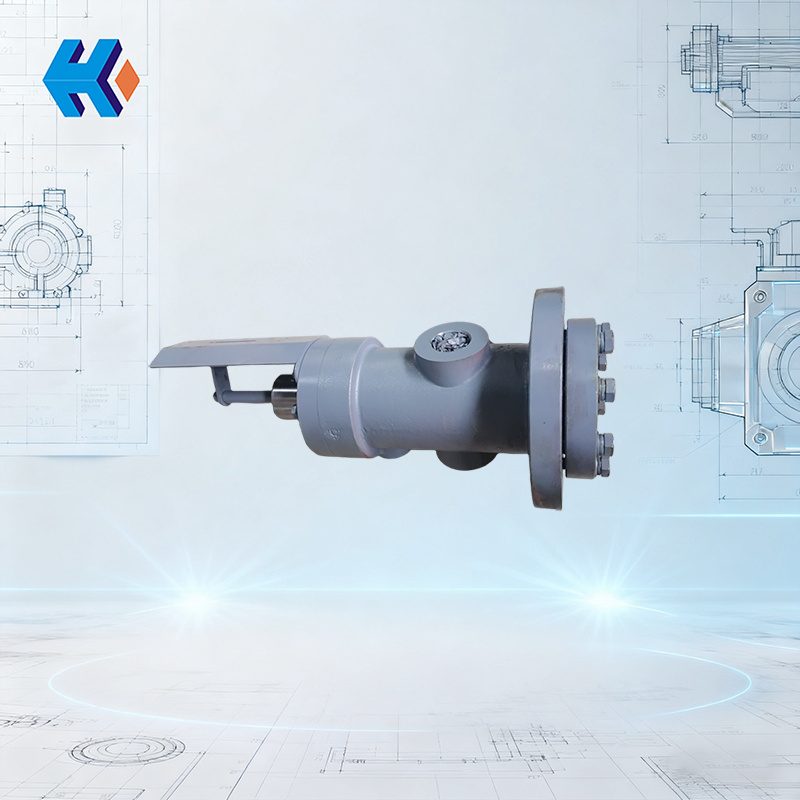

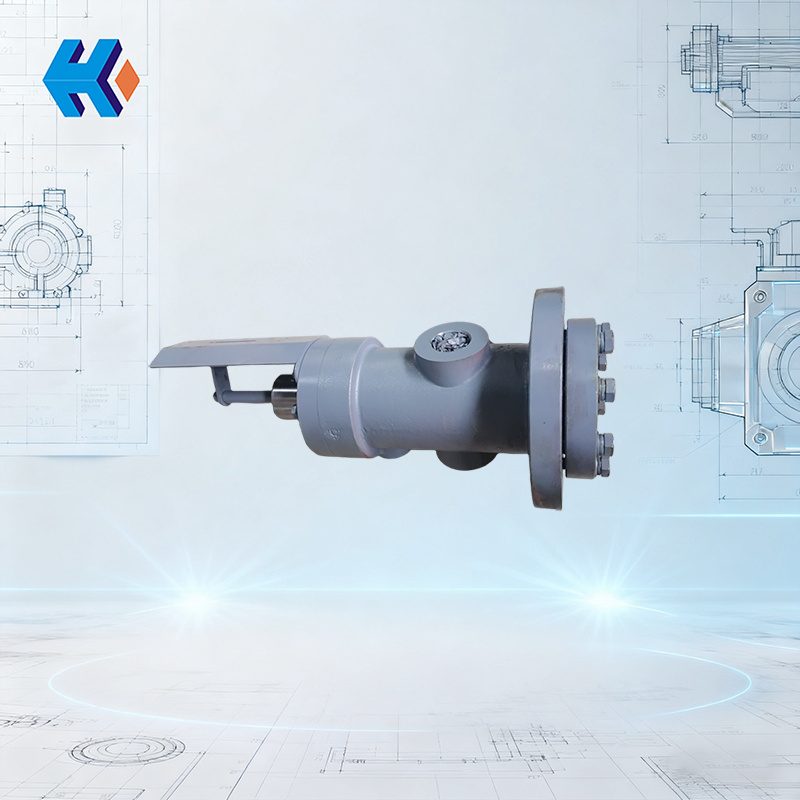

MG00.11.19.01 Hydraulic Directional Valve for Coal Mill

Description of MG00.11.19.01 Hydraulic Directional Valve

The hydraulic directional valve MG00.11.19.01 is a core control element in the hydraulic system of coal mills. It achieves spool direction change through control oil and is vertically installed on the mill. Its precise action directly determines the operating status of the mill’s loading cylinders, playing a vital role in the stable operation of the mill.

Working of MG00.11.19.01 Hydraulic Directional Valve

The working status of the hydraulic directional valve MG00.11.19.01 is closely related to the electromagnetic directional valve. When the electromagnetic valve is in the right position, the control oil chamber of the hydraulic valve is connected to the tank, and the spool is at its highest position under the action of its own structure or reset device. In this state, the return oil chambers of the three loading cylinders are directly connected to the tank, allowing smooth discharge of oil and replenishment, ensuring oil balance in the non-working state and preparing for subsequent actions. This design avoids unnecessary oil retention and ensures flexible cylinder response.

When the grinding roller needs to be lifted or lowered, the electromagnetic valve switches to the left position, and control oil enters the control oil chamber of the hydraulic valve MG00.11.19.01. Under oil pressure, the spool is pushed to the lowest position, isolating the return oil chambers of the three cylinders. Oil return now must pass through flow control and electromagnetic valves, allowing precise control of oil flow speed by adjusting the flow valve opening, ensuring synchronized lifting of the three cylinders. This synchronization is crucial for stable roller operation, avoiding uneven forces and increased vibration, reducing mechanical wear and extending mill life.

To monitor spool position in real time, the hydraulic valve is equipped with two limit switches. When the spool reaches the highest or lowest position, the switches are triggered, sending position signals to the mill control system. Operators can monitor the valve status in real time and handle abnormalities such as spool sticking or incomplete direction change, improving operational safety and monitoring capability.

During daily maintenance, the hydraulic directional valve MG00.11.19.01 should be regularly inspected and serviced. Focus on spool movement flexibility, checking for sticking; limit switch sensitivity, ensuring accurate signals; and regular oil testing and replacement to avoid contamination that may block oil passages or worsen spool wear. Seals and other wear parts should be replaced according to specified cycles to prevent oil leakage that may affect valve performance.

HKZX-2025-10-11-A