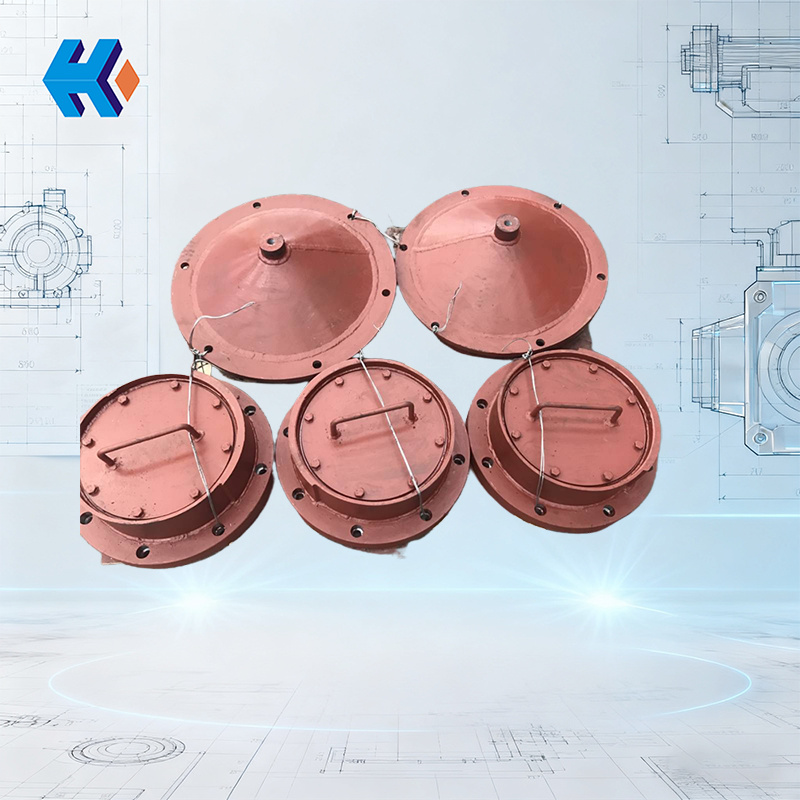

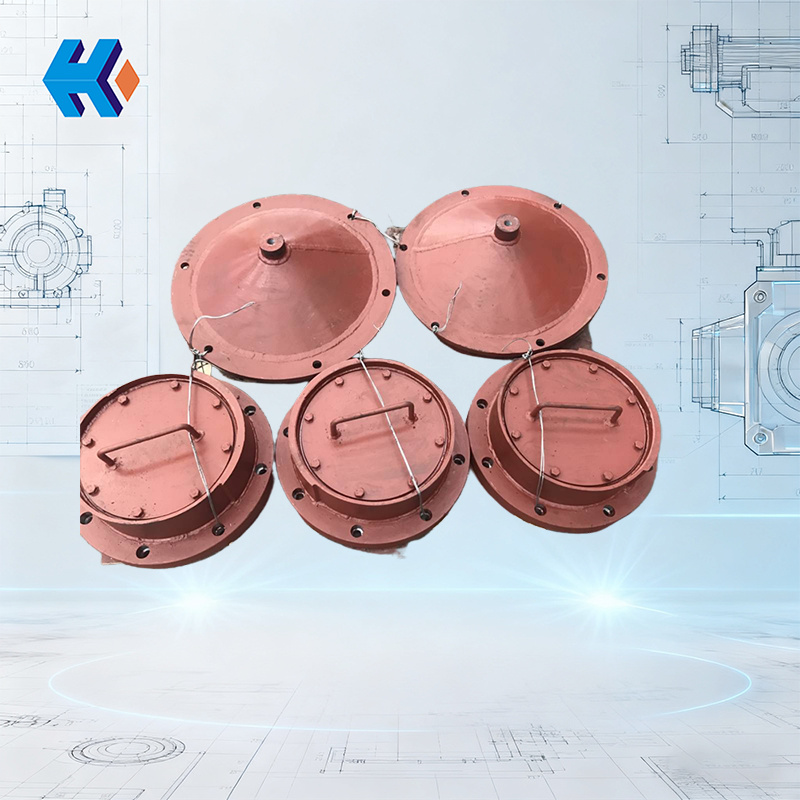

20MG40.11.09.03 grinding roller protective cover

Description of 20MG40.11.09.03 grinding roller protective cover

The protective cover 20MG40.11.09.03 adopts a **split-type modular structure**, consisting of four parts: outer shell, inner buffer layer, sealing flange, and fastening components. The outer shell is made of low-alloy high-strength steel, stamped and formed, then sandblasted and coated with two layers of epoxy zinc-rich primer and one layer of wear-resistant polyurethane topcoat, ensuring both structural rigidity and excellent corrosion resistance. The inner buffer layer is made of 5mm thick nitrile rubber sheet, vulcanized and bonded tightly to the inner wall of the shell, effectively absorbing high-frequency vibrations generated by the shaft head during operation, while reducing the impact force from external object collisions. The sealing flange adopts a mortise-and-tenon joint design, with oil-resistant asbestos packing embedded in the connection surface to the shaft head base, and is fastened with grade 12.9 high-strength bolts, ensuring good sealing performance under high temperatures (≤120℃) and negative pressure during coal mill operation, preventing leakage of coal powder and lubricating oil.

Working principle of 20MG40.11.09.03 grinding roller protective cover

During coal mill operation, the shaft head rotates at high speed (300–500 r/min). The protective cover prevents operator contact with rotating parts, avoiding mechanical injury, and blocks flying coal chunks and metal debris from impacting the shaft head directly, preventing shaft surface scratches or keyway damage. Secondly, it acts as an environmental barrier. The coal mill working environment contains a large amount of coal powder (particle size ≤0.1mm) and sulfur-containing moisture. The protective cover, through a labyrinth sealing structure, reduces dust intrusion into the shaft bearing chamber, lowers the probability of grease contamination, and blocks moisture contact with the shaft surface, slowing oxidation and rust.

The flange surface of the protective cover is machined to IT7 precision, with a fit clearance of 0.05–0.1 mm to the shaft head base, ensuring no radial after installation. Two φ80 mm inspection windows are provided on the side of the shell, equipped with quick-opening covers, allowing easy inspection of shaft seal conditions and grease replenishment without removing the entire cover. Additionally, four φ12 mm dust discharge holes are designed at the bottom of the cover to periodically remove accumulated fine coal powder and prevent long-term buildup from forming safety hazards.

HKZX-2025-10-10-A