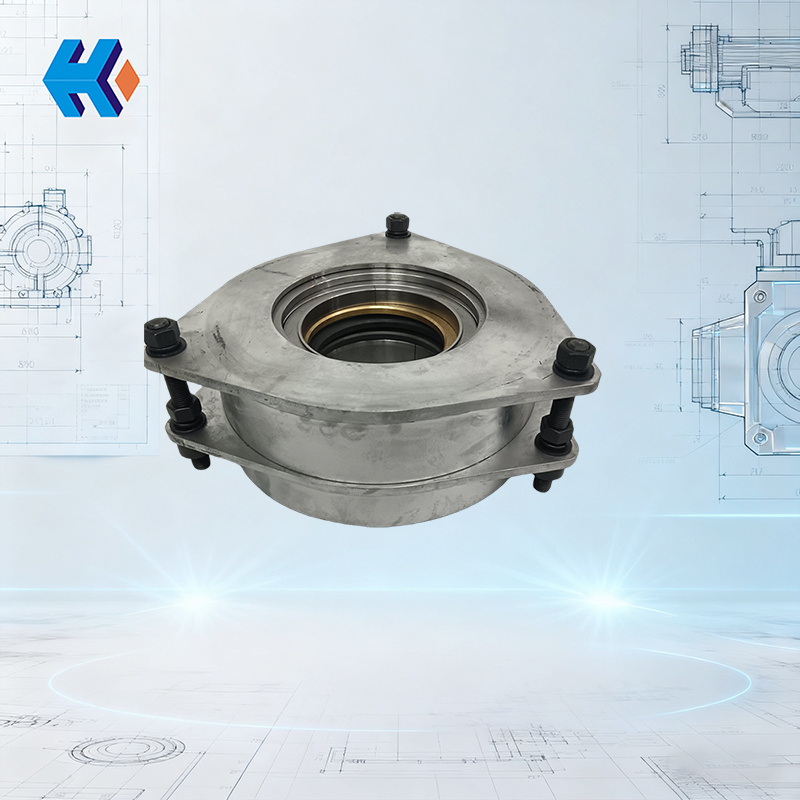

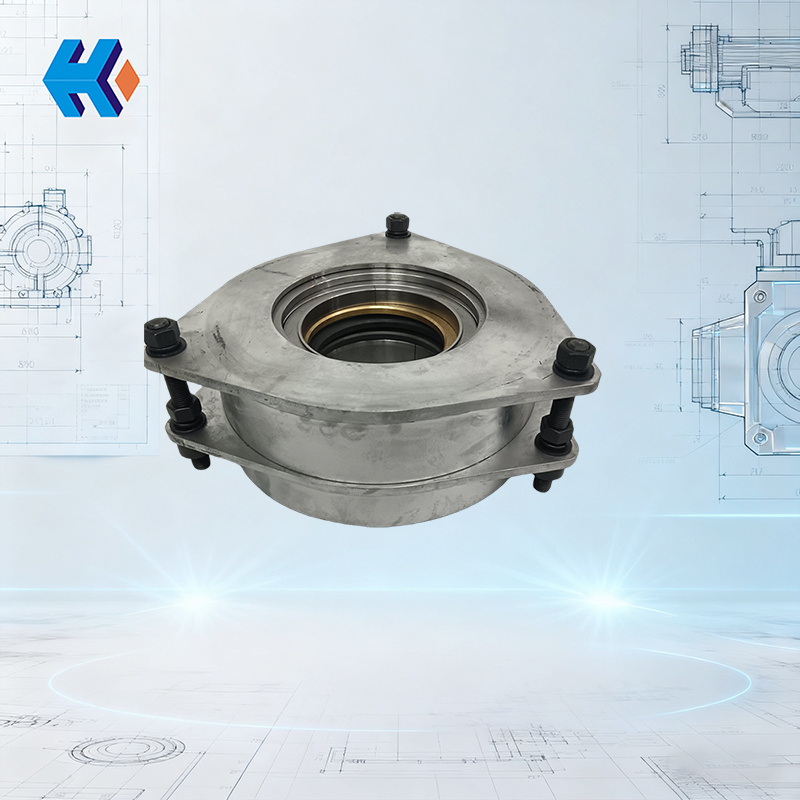

331MG41.11.12B.06 rod seal

Description of coal mill rod seal 331MG41.11.12B.06

The rod seal 331MG41.11.12B.06 is primarily used to prevent powder accumulation between the joint bearing and the sealing ring. During coal mill operation, the internal environment is complex, and coal powder particles are carried by airflow and dispersed everywhere. The rod, as a moving part in the coal mill structure, is prone to coal powder accumulation at its connection points with the joint bearing and sealing ring without effective sealing measures. Over time, this accumulation reduces the flexibility of the joint bearing, increases mechanical wear, affects the normal movement of the rod, and ultimately impacts the overall stability of the coal mill.

Effect of 331MG41.11.12B.06 rod seal

The rod seal device installed at the casing penetration point of the rod also plays a vital role. On one hand, it ensures that coal powder does not leak out through the gap between the casing and the rod, avoiding environmental pollution. On the other hand, it ensures that the rod can move freely up and down without being hindered by the sealing device, so it can perform its tasks normally, such as adjusting the position of certain internal components.

The rod seal 331MG41.11.12B.06 cleverly utilizes specific structures and sealing methods. Internally, it typically adopts a multi-layer sealing structure, which may include sealing rings, gaskets, and specially designed labyrinth-type sealing channels. These structures work together: when coal powder attempts to pass through the gap between the rod and surrounding components, it first encounters the resistance of the sealing ring, which fits tightly around the rod surface, reducing the space for coal powder to pass. Meanwhile, the labyrinth design forces the coal powder to undergo multiple bends and obstructions, greatly increasing the difficulty of leakage. Additionally, the rod seal utilizes a certain amount of sealing air (about 5% of the total air volume), introduced from a specific inlet, forming an air barrier in the sealing area. This airflow not only blows away coal powder particles approaching the seal but also maintains pressure balance in the sealing area, further preventing external coal powder intrusion and ensuring the joint bearing and sealing ring remain clean and free of powder accumulation.

Since the rod seal 331MG41.11.12B.06 operates long-term in an environment filled with coal powder, its material must have good wear resistance to withstand continuous scouring without failure, ensuring long-term sealing effectiveness. Common materials include polyurethane and fluororubber. Polyurethane offers high strength and wear resistance, along with good elasticity, maintaining tight contact with the rod surface during movement.

HK2025-09-29-A