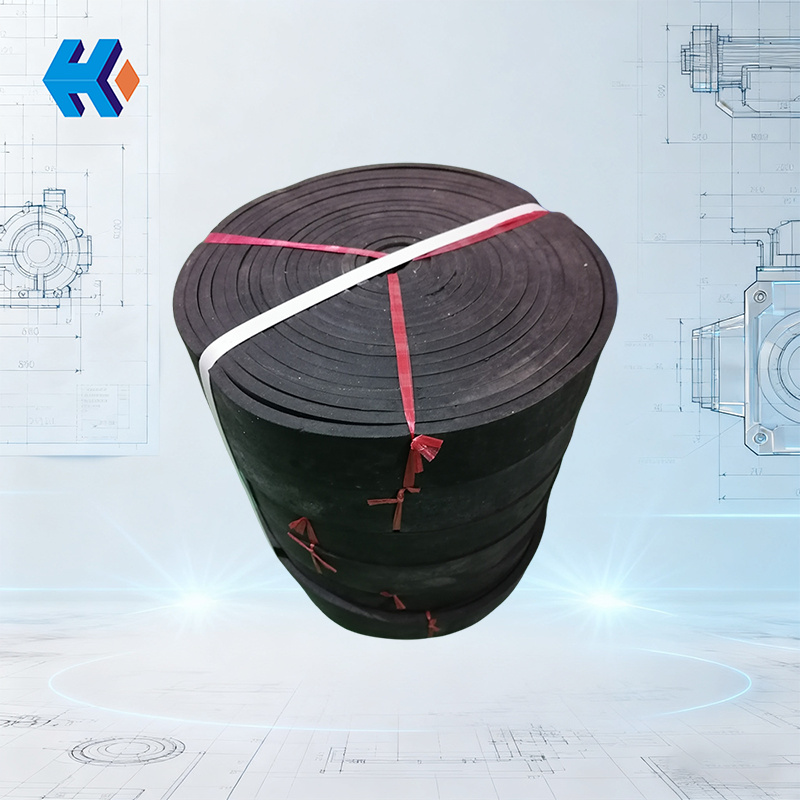

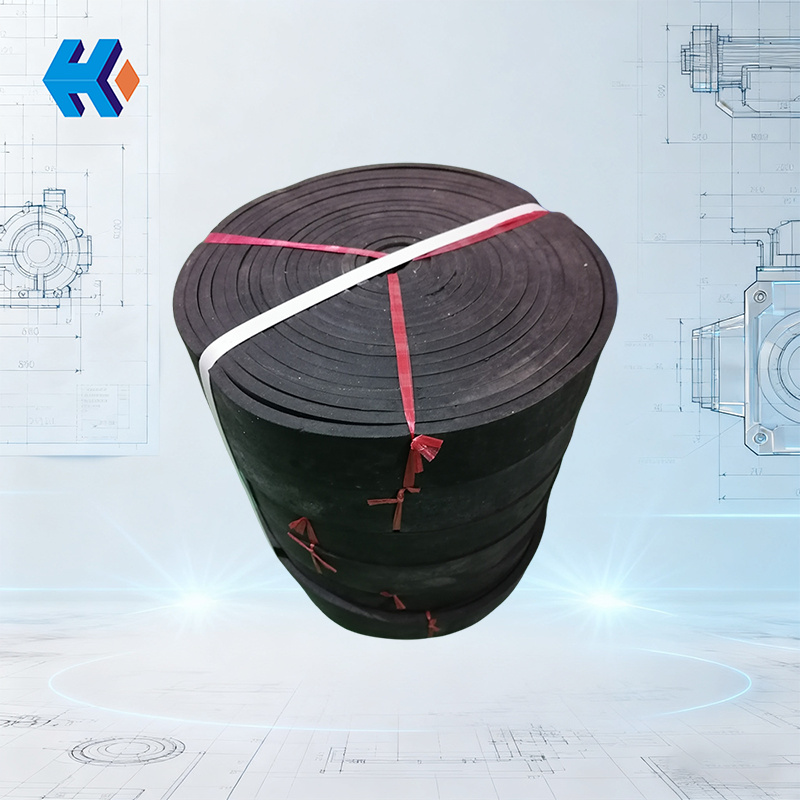

60x10x10m Induced draft fan lining belt liner

Description of 60x10x10m Induced draft fan lining belt liner

In the operational system of an induced draft fan, the Induced draft fan lining belt liner 60×10×10 m and made of foam rubber can be well adapted whether used in long-distance sealing parts of large fans or in specific structures of small fans. Its thickness ensures sufficient strength and toughness to withstand various forces generated during fan operation, without affecting installation space or adding unnecessary weight due to excessive thickness.

Feature of 60x10x10m Induced draft fan lining belt liner

The fan liner is made of foam rubber, a material processed through special techniques. Foam rubber introduces specific foaming agents into the rubber matrix; during processing, these agents decompose under heat to produce gas, forming a large number of tiny bubble structures inside the rubber. This unique microstructure endows foam rubber with many excellent properties. During fan operation, strong vibrations and noise are generated inside the equipment. The bubble structure within the foam rubber acts like springs, effectively absorbing and buffering vibrational energy, reducing the transmission of vibrations to other parts, and lowering equipment wear caused by vibration, thus extending service life. For example, in complex working conditions with severe vibrations, foam rubber liners can significantly reduce the failure rate of equipment. At the same time, these bubble structures can also block and absorb sound, reducing noise during fan operation and providing a quieter working environment for operators.

Foam rubber liners also have excellent sealing performance. During fan operation, internal gases need to flow along specific paths to ensure efficient operation. If gas leakage occurs, it not only reduces fan efficiency but may also lead to energy waste and environmental pollution. The surface of the foam rubber liner can tightly fit the surfaces of fan components. Even if there are slight irregularities on the component surfaces, its good flexibility and elasticity allow the liner to adapt perfectly, filling possible gaps and effectively preventing gas leakage. For instance, at the connection between the impeller and casing of an induced draft fan, the foam rubber liner can form a reliable sealing barrier, ensuring normal gas flow inside the fan.

In addition, foam rubber materials have good corrosion resistance and weather resistance. The working environment of induced draft fans is often harsh, possibly involving humid air, corrosive gases, or dust. Foam rubber can resist erosion from these adverse factors, maintaining stable performance over long-term use without degradation, aging, or cracking due to corrosion. For example, in chemical plant induced draft fans, even when surrounded by highly corrosive chemicals, foam rubber liners can operate stably for extended periods, ensuring normal fan operation.

HK2025-09-29-A