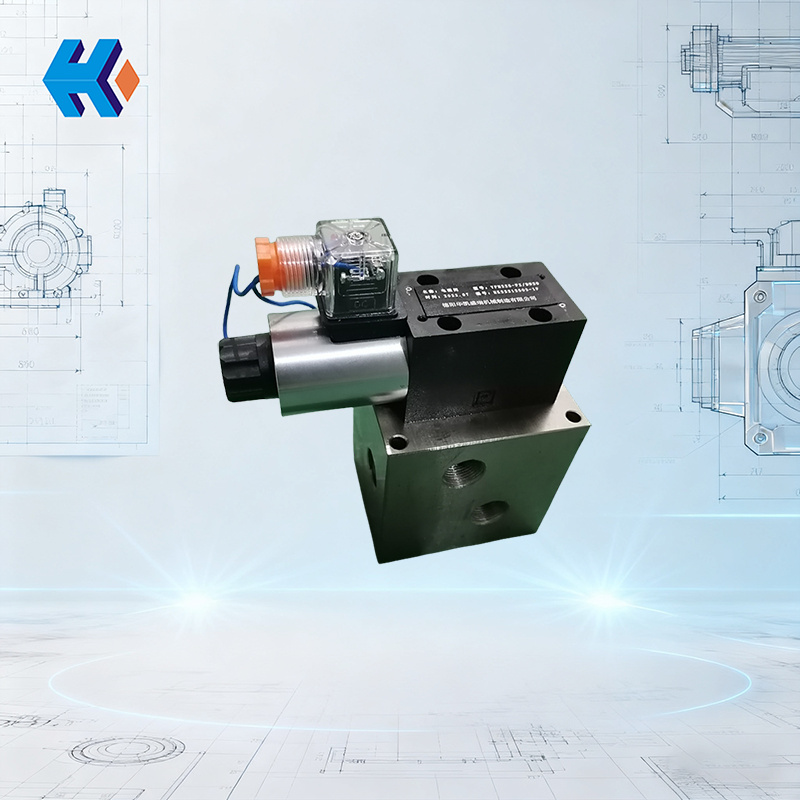

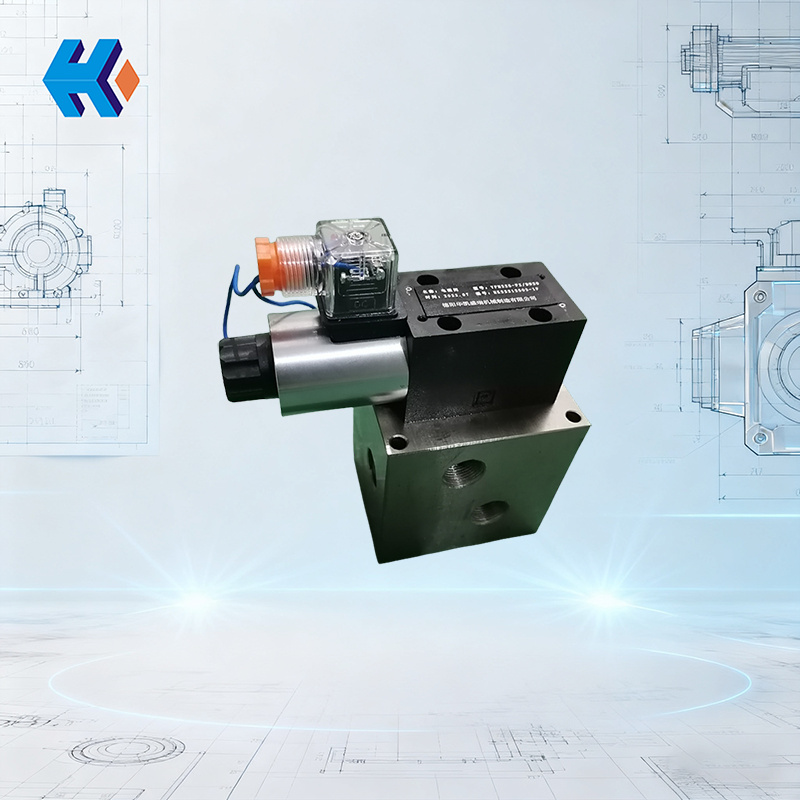

YPM225-FZ DN20 A/B double-sided directional Solenoid valve

Description of Double-sided directional Solenoid valve YPM225-FZ DN20

Double-sided directional Solenoid valve YPM225-FZ DN20 is widely used in the hydraulic control system of large equipment such as coal mills.

double-sided directional Solenoid valve YPM225-FZ DN20 is the layout of the/B two sides. This design means that the two working oil ports A and B in the valve body can realize two-way circulation, breaking the passage restriction of the traditional one-way reversing valve, and can flexibly switch the flow direction of the oil according to the system requirements. The valve body adopts precision machining valve core and valve sleeve matching structure, the valve core surface after special wear-resistant treatment, to ensure that in the high frequency reversing operation can still maintain good sealing and movement accuracy. At the same time, the valve body adopts the overall casting process, the selection of high-strength ductile iron material, not only has excellent pressure resistance, can withstand the long-term impact of the system high-pressure oil, but also can effectively resist the vibration and temperature changes in the working environment, to ensure the stability of the valve body structure.

Working principle of Double-sided directional Solenoid valve YPM225-FZ DN20

When the equipment is in the regular operation mode, the control system sends a signal to drive the valve core in the neutral position. At this time, the oil ports A and B are connected with the oil return chamber, and the oil can flow smoothly back to the oil tank through the oil return pipe to ensure that the system is not Maintaining low-pressure balance under working conditions. When the reversing operation needs to be performed, the control system drives the valve core to move through electromagnetic or hydraulic mode, so that the oil port is connected with the oil inlet cavity, the B oil port is connected with the oil return cavity, or the B oil port is connected with the oil inlet cavity, and the oil port is connected with the oil return cavity to realize the rapid switching of the oil flow direction. Due to the/B two-sided design, the oil flow loss in the switching process is small, the response speed is fast, and it can meet the needs of the coal mill and other equipment for the rapid action of the actuator, such as the control of the lifting of the grinding roller, the opening and closing of the gate and other key operations.

HKZX-2025-09-29-A